Anti-acarid and antibacterial finishing agent as well as finishing method and application thereof

An antibacterial finishing agent and anti-mite technology, which is applied in fiber treatment, textile and papermaking, biochemical fiber treatment, etc., can solve the problems of large performance decline, achieve long-lasting durability, improve the durability of anti-mite and antibacterial functions, and have good antibacterial properties. The effect of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of anti-mite and antibacterial finishing agent includes the following steps:

[0024] S1. Add 9 parts of 3-(3-hydroxyphenyl) propionic acid, 9 parts of linalool and 30 parts of deionized water into the reaction kettle, fully stir, heat up to 90°C, stir and react for 5 hours to obtain product A;

[0025] S2. Add 6 parts of licorice chalcone, 8 parts of methacrylic acid and 20 parts of deionized water into the reaction kettle, raise the temperature to 60°C, and then add 0.5 part of dibenzoyl peroxide dropwise, after 0.5 hours of dripping, then Begin to heat up to 85°C, stir and react for 4h, add 20 parts of dihydrokaempferol and 10 parts of deionized water within 0.5h, stir and react for 3h, after the reaction, the temperature of the mixed solution is rapidly reduced to 20°C to obtain product B;

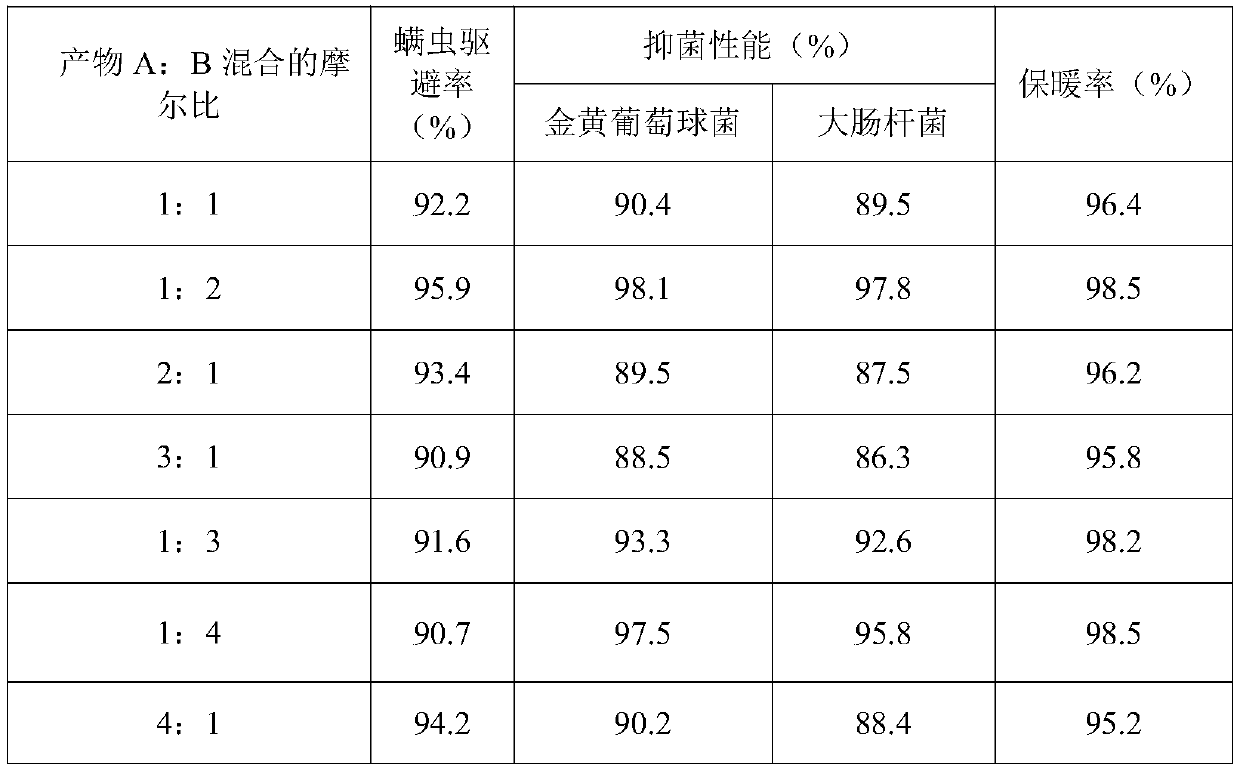

[0026] S3. After mixing product A and product B in a ratio of 1-4:1-4, an anti-mite and antibacterial finishing agent is obtained.

[0027] Finishing the fabric by ...

Embodiment 2

[0034] A preparation method of anti-mite and antibacterial finishing agent includes the following steps:

[0035] S1. Add 6 parts of 3-(3-hydroxyphenyl) propionic acid, 6 parts of linalool and 30 parts of deionized water into the reaction kettle, fully stir, heat up to 90° C., stir and react for 5 hours to obtain product A;

[0036] S2. Add 4 parts of licorice chalcone, 5 parts of methacrylic acid and 20 parts of deionized water into the reaction kettle, raise the temperature to 60°C, and then add 0.3 part of dibenzoyl peroxide dropwise, after 0.5 hours of dropping, then Begin to heat up to 85°C, stir and react for 4h, add 10 parts of dihydrokaempferol and 10 parts of deionized water within 0.5h, stir and react for 3h, after the reaction, the temperature of the mixed solution is rapidly reduced to 20°C to obtain product B;

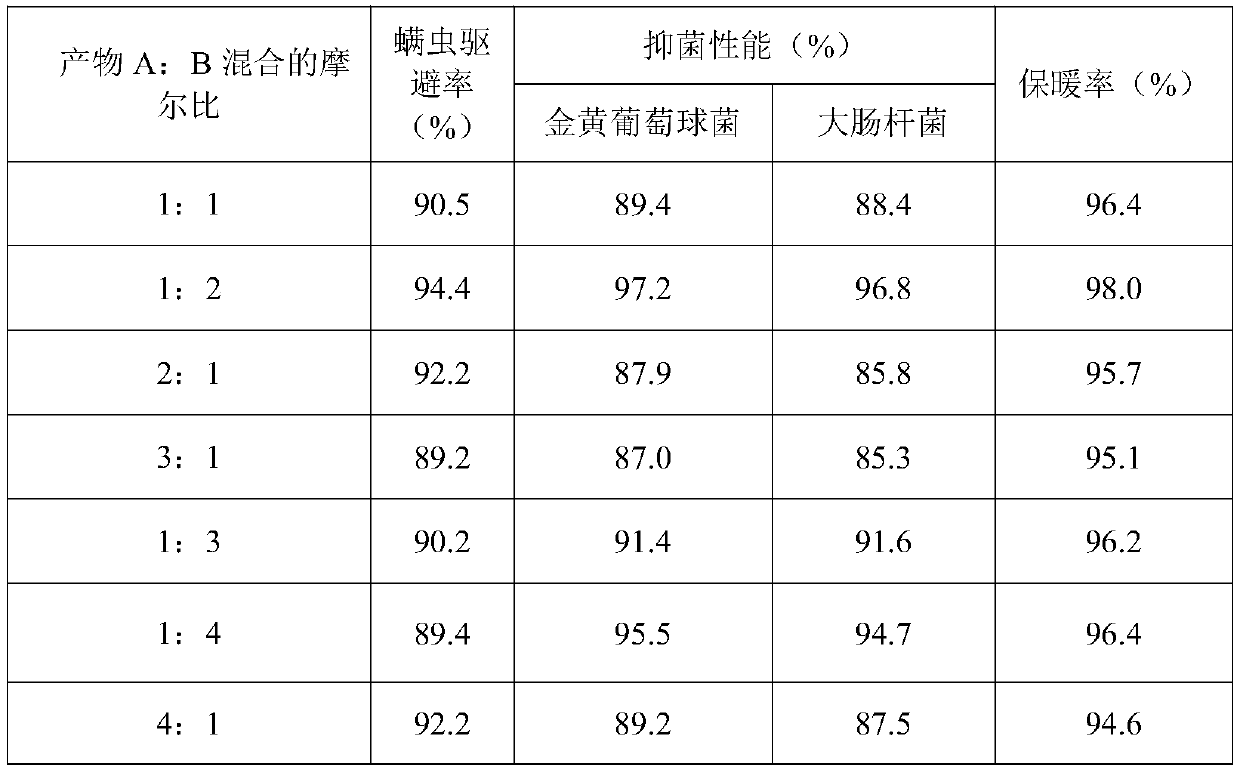

[0037] S3. After mixing product A and product B in a ratio of 1-4:1-4, an anti-mite and antibacterial finishing agent is obtained.

[0038] Finishing the fabric b...

Embodiment 3

[0045] A preparation method of anti-mite and antibacterial finishing agent includes the following steps:

[0046] S1. Add 9 parts of 3-(3-hydroxyphenyl) propionic acid, 9 parts of linalool and 30 parts of deionized water into the reaction kettle, fully stir, heat up to 90°C, stir and react for 5 hours to obtain product A;

[0047] S2. Add 6 parts of licorice chalcone, 8 parts of methacrylic acid and 20 parts of deionized water into the reaction kettle, raise the temperature to 60°C, and then add 0.5 part of dibenzoyl peroxide dropwise, after 0.5 hours of dripping, then Begin to heat up to 85°C, stir and react for 4h, add 20 parts of dihydrokaempferol and 10 parts of deionized water within 0.5h, stir and react for 3h, after the reaction, the temperature of the mixed solution is rapidly reduced to 20°C to obtain product B;

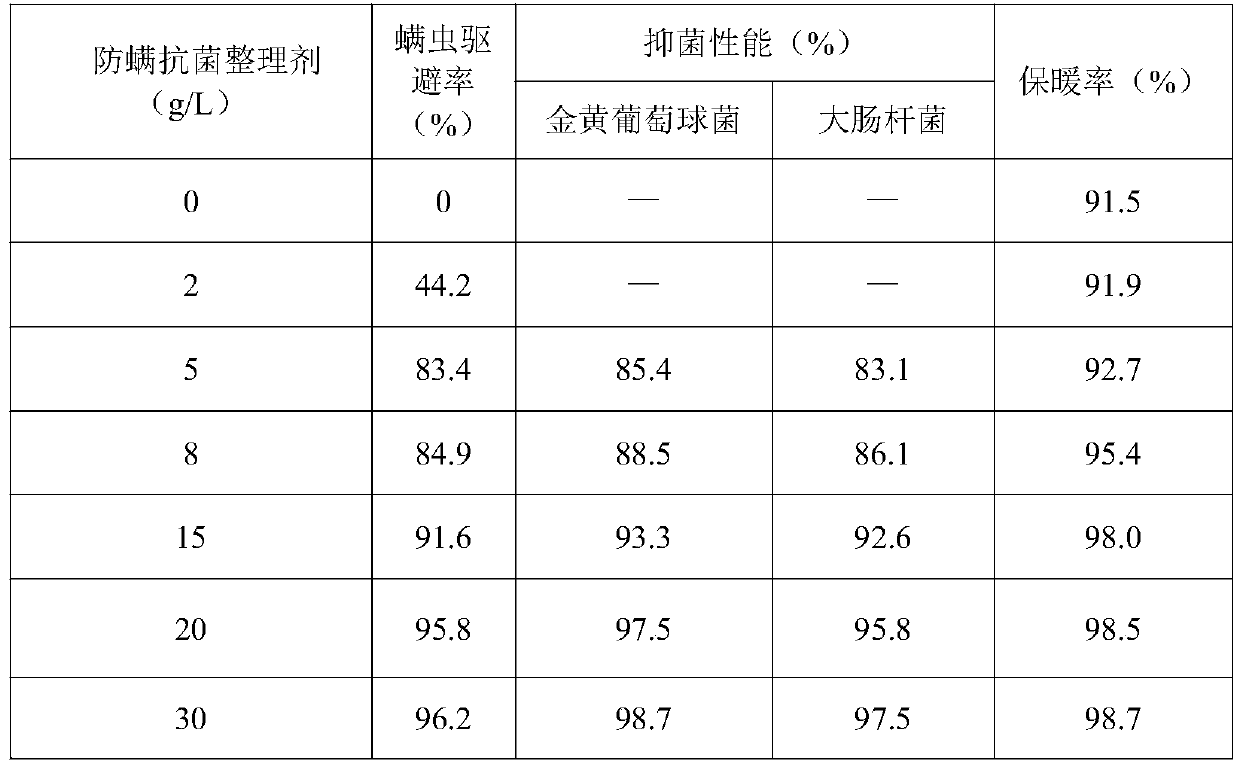

[0048] S3. The anti-mite and antibacterial finishing agent is obtained by mixing the product A and the product B in a ratio of 1:2.

[0049] Finishing the fabric by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com