Preparation and application method of long-life friction-sensitive graphdiyne-based piezoelectric material

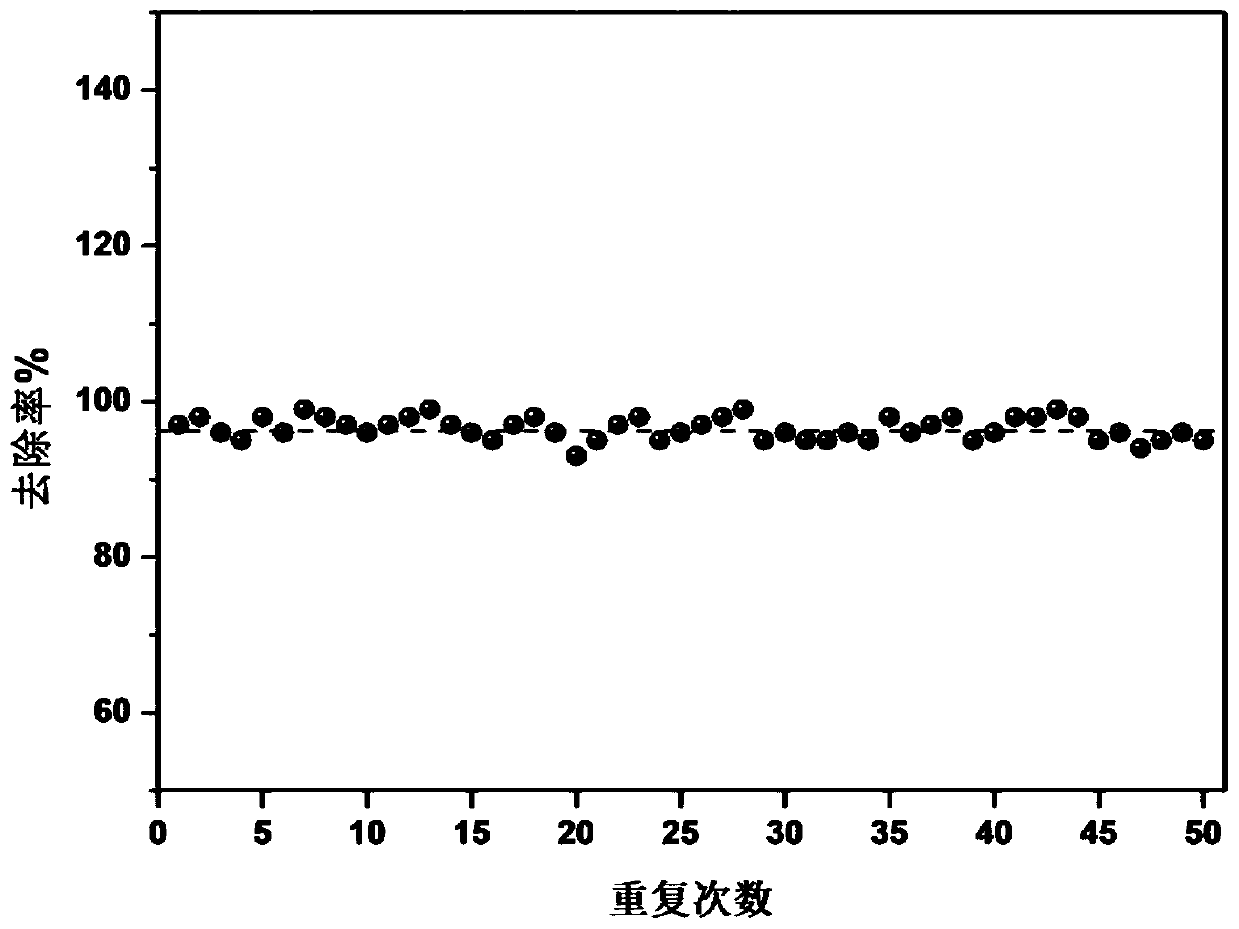

A technology of graphyne and electrical materials, applied in chemical instruments and methods, electrochemical water/sewage treatment, physical/chemical process catalysts, etc., can solve problems such as activity reduction, active site destruction, and catalytic activity maintenance, and achieve pore Multi-stage, low-cost, distinct friction-response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

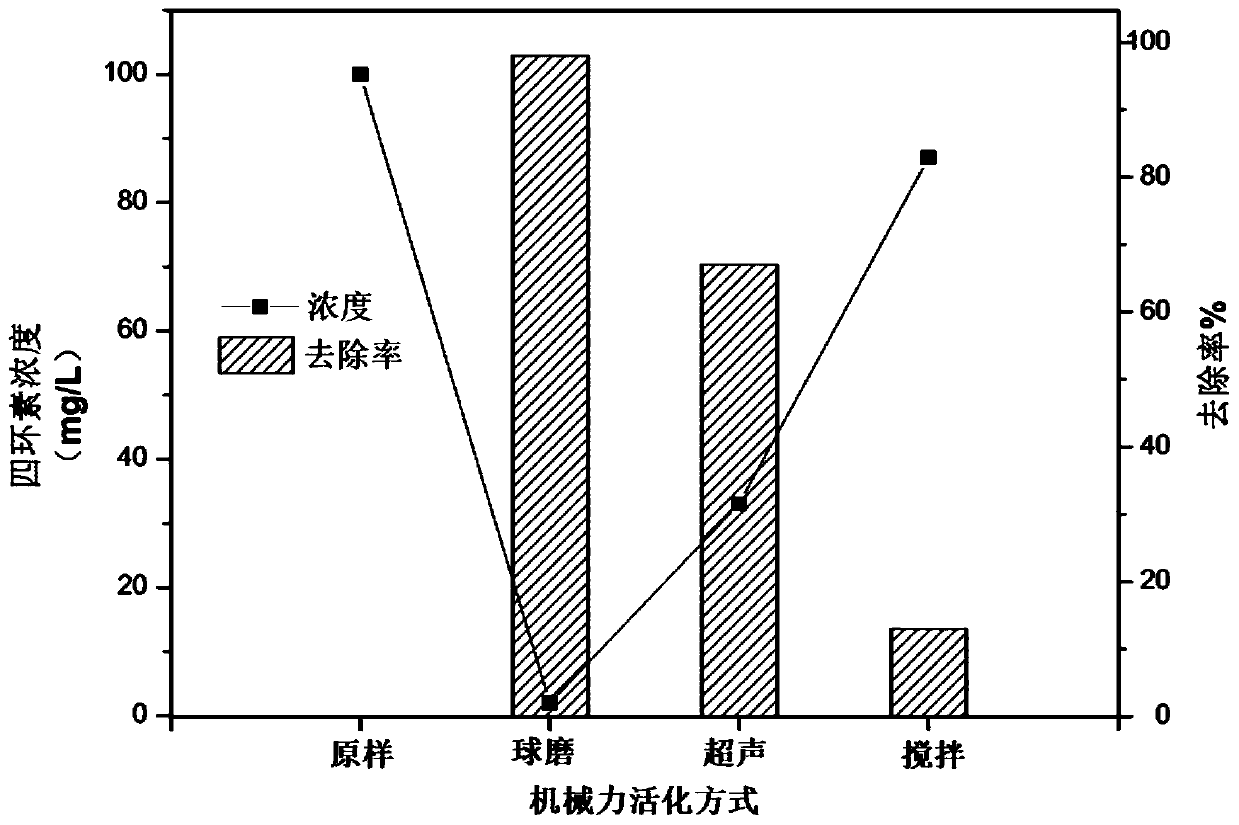

[0028] 1) Take hexabromobenzene and calcium carbide according to a molar ratio of 1:6, place in a 100mL vacuum polytetrafluoro ball mill reactor, add 50 milliliters of ethanol, add 100g of zirconia balls with a diameter of 4mm as a medium, and pump Vacuum, ball milling for 8 hours under the condition of rotating speed of 800 rpm.

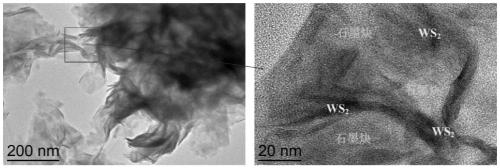

[0029] 2) The powder sample after ball milling was taken out, washed twice with deionized water and ethanol sequentially, and dried at 90°C for 10 h to obtain thin-layer graphdiyne powder.

[0030] 3) Weigh tungsten dioxide, thiourea and sodium hydroxide according to the molar ratio of 1:10:0.1, and place them in a 100mL polytetrafluoro ball mill reactor.

[0031] 4) Weigh the graphdiyne powder obtained in step 2) with a mass of 0.2 g, add it to the reaction kettle of step 3), and ball mill it for 3 hours at 800 rpm to obtain the graphyne-based composite piezoelectric catalytic material precursor powder .

[0032] 5) Put the precursor powder obtai...

Embodiment 2

[0037] 1) Weigh hexahalobenzene and calcium carbide according to the molar ratio of 1:8, place in a 100mL vacuum polytetrafluoro ball mill reactor, add 200g of zirconia balls with a diameter of 4mm as the medium, vacuumize, and Under the condition of 1000 rev / min, ball mill for 6h.

[0038] 2) The powder sample after ball milling was taken out, washed twice with deionized water and ethanol sequentially, and dried at 80° C. for 6 hours to obtain thin-layer graphdiyne powder.

[0039] 3) Weigh ammonium molybdate, thiourea and sodium hydroxide according to the molar ratio of 1:8:0.5, and place them in a 100mL polytetrafluoro ball mill reactor.

[0040] 4) Weigh the graphyne powder obtained in step 2) with a mass of 0.1 g, add it to the reaction kettle of step 3), and ball mill it for 5 hours at 800 rpm to obtain the graphyne-based composite piezoelectric catalytic material precursor powder .

[0041] 5) Put the precursor powder obtained in step 4) in the tube furnace, under N ...

Embodiment 3

[0047] 1) Weigh hexahalobenzene and calcium carbide according to the molar ratio of 1:4, place in a 100mL vacuum polytetrafluoro ball mill reaction kettle, add 200g of zirconia balls with a diameter of 6mm as the medium, vacuumize, at a speed of Under the condition of 1000 rev / min, ball mill for 6h.

[0048] 2) Remove the ball-milled sample, wash twice with deionized water and ethanol in sequence, and dry to obtain thin-layer graphdiyne powder.

[0049] 3) Weigh Bi(OH) according to the molar ratio of 4:3 3 with Ti(OH) 4 Powder, placed in a 100mL polytetrafluoro ball mill reactor.

[0050] 4) Weigh the graphyne powder obtained in step 2) with a mass of 0.5 g, add it to the reaction kettle of step 3), and ball mill it for 6 hours at 1000 rpm to obtain the graphyne-based composite piezoelectric catalytic material precursor powder .

[0051] 5) Put the precursor powder obtained in step 4) in the tube furnace, under N 2 Under atmosphere, activate at 250°C for 4h, then cool to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com