Universal preparation method and application of active site combined with air electrode structure

A technology of active sites and air electrodes, applied in structural parts, battery electrodes, circuits, etc., can solve the problems of slow electrochemical reaction of oxygen, achieve high energy density, increase mass transfer rate, and increase reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

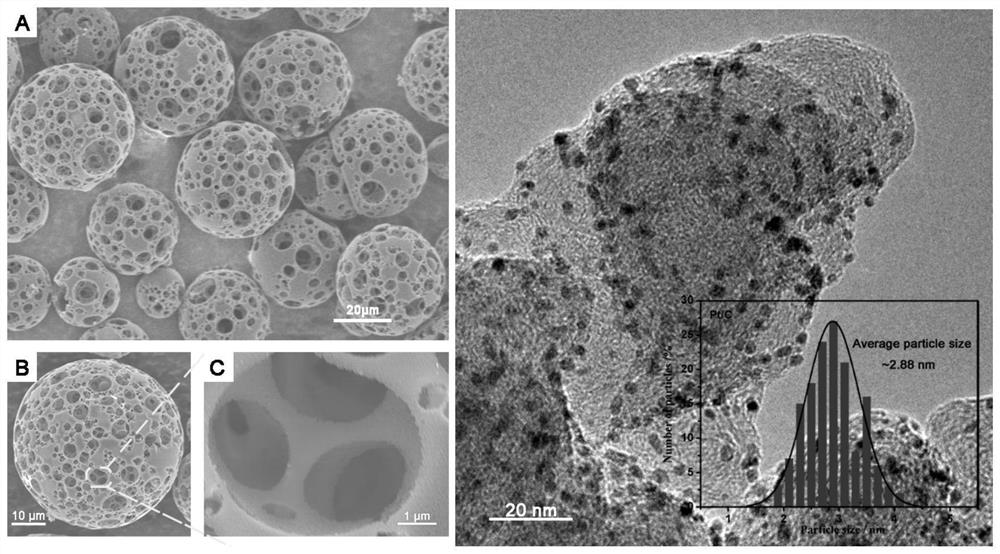

[0053] A highly connected multi-level porous skeleton carbon microsphere loaded trace precious metal platinum catalyst, its precursor includes macropores, mesoporous, The highly interconnected hierarchical porous framework carbon microspheres inside the micropores; and the platinum chloride required for the in-situ reduction of loaded platinum nanoparticles to the above-mentioned internal highly interconnected hierarchical porous framework carbon microspheres prepared by the in situ loading noble metal method acid and reducing agent sodium borohydride.

[0054] The preparation method of the above-mentioned highly connected multi-level porous skeleton carbon microspheres loaded with a small amount of precious metal platinum catalyst is as follows: first, the polymer microspheres are cross-linked by carbon tetrachloride cross-linking method. The specific steps are as follows: 0.1g polymer microspheres and 30ml of carbon tetrachloride in a 50ml glass bottle, shake evenly at 70°C ...

Embodiment 2

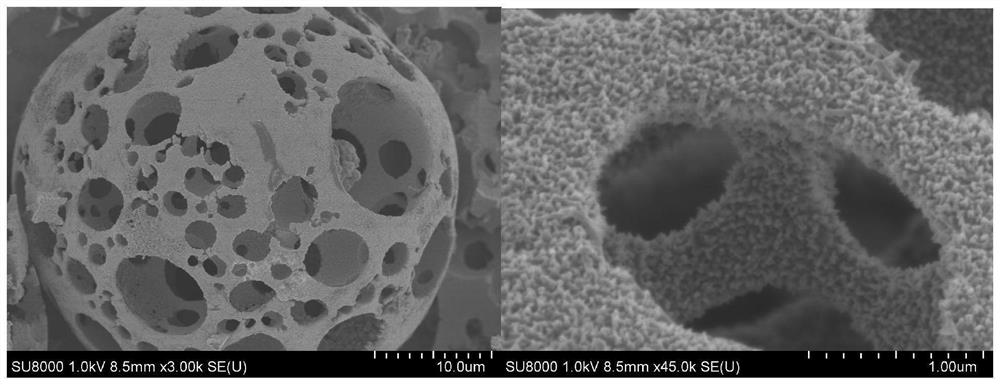

[0056] A polyaniline array-coated hierarchical porous carbon microsphere air cathode catalyst, its precursor and the method used are hierarchical porous polymer microspheres and polyaniline coating prepared by concentrated sulfuric acid Aniline array coated sulfonated polymer microspheres, and nitrogen-containing polyaniline array hierarchical porous microspheres treated with ammonia gas activation.

[0057] The specific method of the above-mentioned polyaniline array-coated hierarchical porous carbon microsphere air cathode catalyst is as follows: the first step is to sulfonate the polymer microsphere with concentrated sulfuric acid sulfonation method, and the specific steps are: pour 50ml of concentrated sulfuric acid into Put 2.0g of polymer microspheres in a 100ml round-bottom flask, treat at 135°C for 5h, pour into 800ml of deionized water under stirring with a glass rod while it is hot, cool and filter, wash with a large amount of water until neutral, and dry at 60°C; In...

Embodiment 3

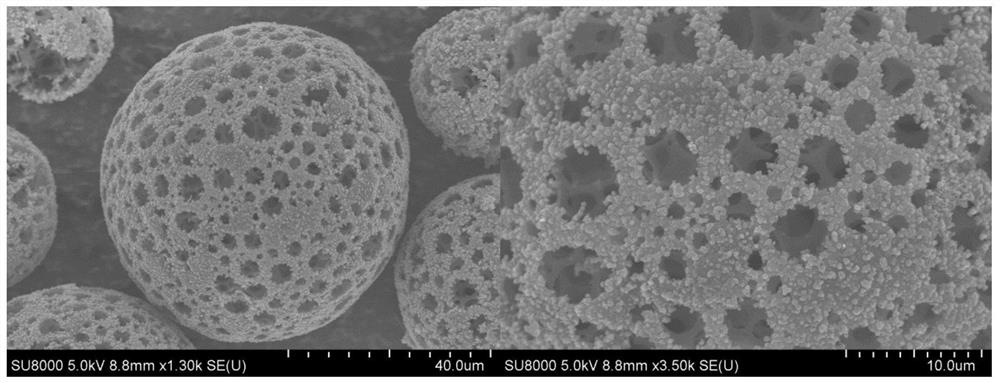

[0059] A nitrogen-sulfur double-doped carbon-based hierarchical porous carbon microsphere air cathode catalyst, the precursors of which are dopamine hydrochloride and mercaptoethylamine, and the methods used are in-situ doping heteroatom method and ammonia gas activation method.

[0060] The preparation method of the above-mentioned nitrogen-sulfur double-doped carbon-based hierarchical porous carbon microsphere air cathode catalyst is as follows: the first step is to mix 0.4g polymer microsphere, 0.8g dopamine hydrochloride and 30ml methanol for 5h, add 0.02M Tris buffer solution 150ml continued to stir for 12h, added 0.32g of mercaptoethylamine, 0.8g of dopamine hydrochloride and 50ml of 0.02M Tris buffer and continued to stir for 24h, filtered and washed, and dried at 60°C; in the second step, the above dopamine and mercaptoethylamine coated polymer The microspheres were activated by ammonia gas. The specific steps were as follows: carbonize the carbon-containing precursor o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com