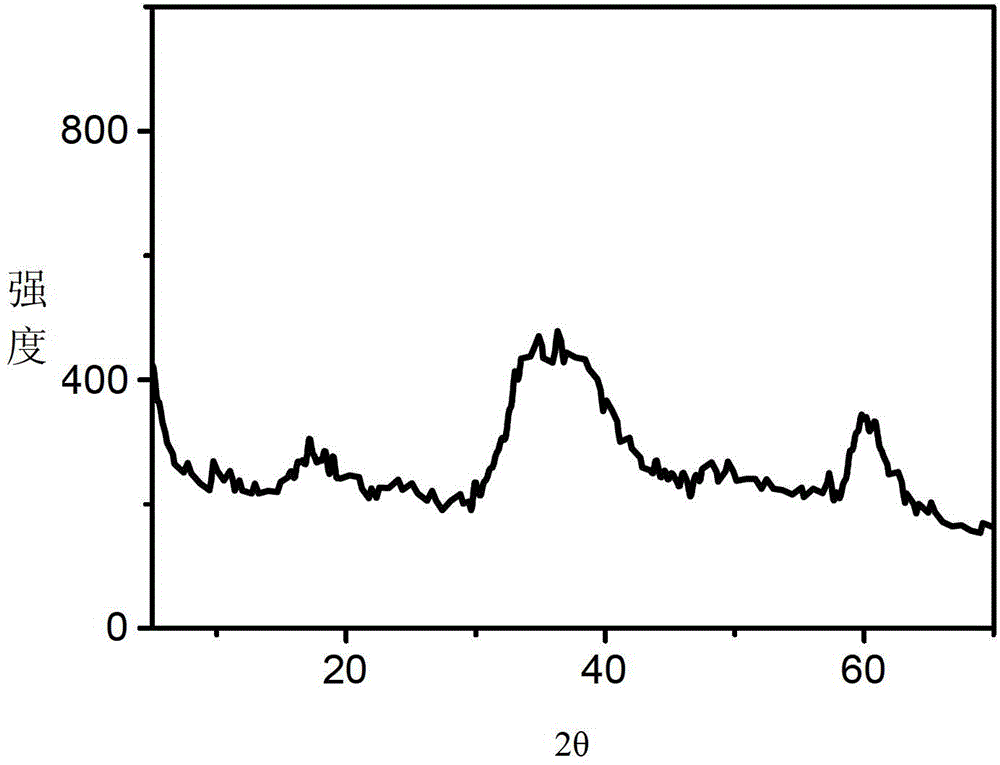

A kind of nickel-based basic nickel carbonate thin film material and preparation method and application thereof

A thin film material, nickel carbonate technology, applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth, etc., can solve the problems of expensive ruthenium materials, limit the popularization of supercapacitors, etc., and achieve large contact area, high capacity and speed. , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

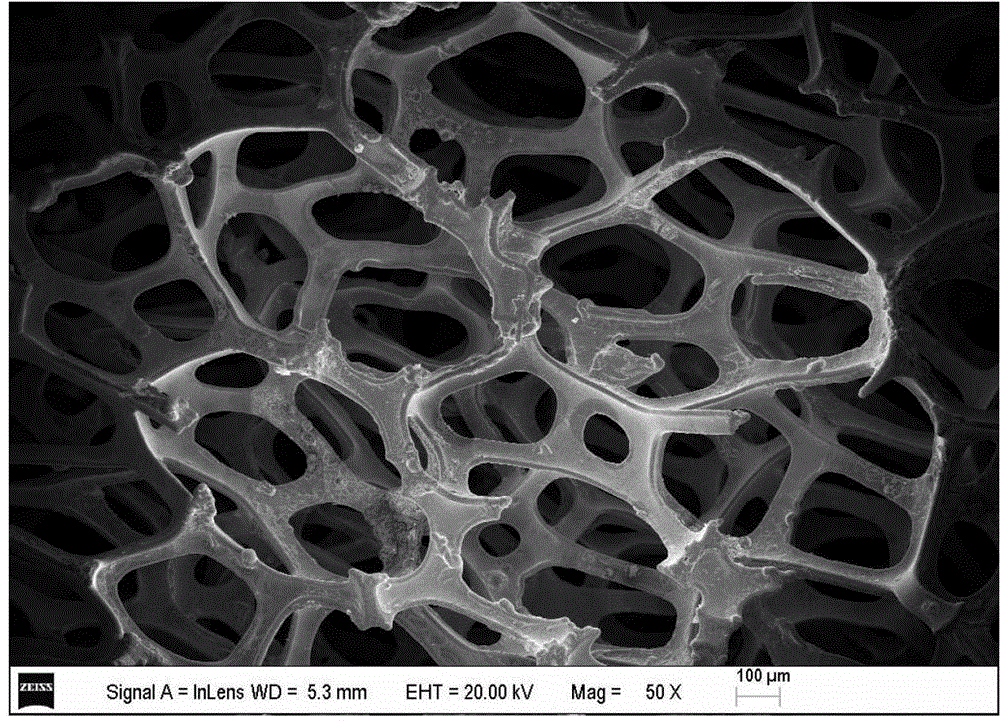

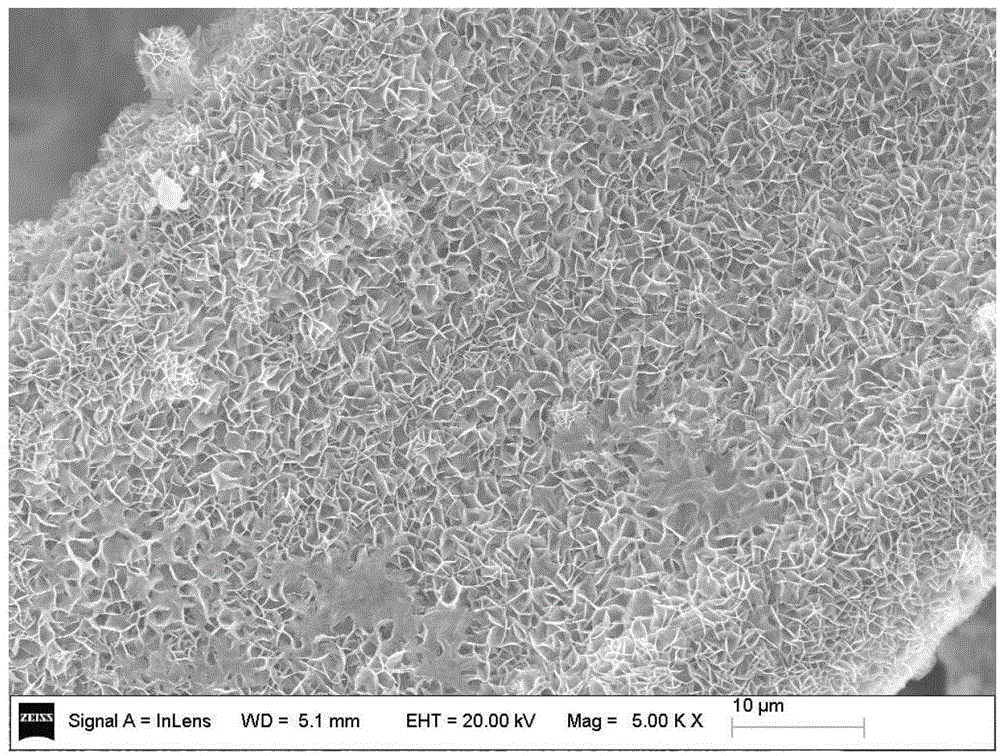

[0029] 1) Use nickel foam sheets with a purity of 95wt% as the substrate, cut them into pieces of 10*15cm in size, ultrasonically clean them with concentrated hydrochloric acid with a mass concentration of 30% for 50 seconds, and then ultrasonically clean them with deionized water for 3 times, and then use absolute ethanol Ultrasonic cleaning once, put into 60 ℃ oven and dry for later use;

[0030] 2) Dilute 58.15g Ni(NO 3 ) 2 Prepare 1000ml nickel nitrate solution; then use deionized water to dissolve 18.65gNaOH and 17.5gNa 2 CO 3 Prepare 200ml of alkali solution; put the foamed nickel sheet treated in step 1) into the nickel nitrate solution, then add the alkali solution drop by drop under stirring until the pH value is 9.5, then transfer it to a polytetrafluoroethylene reactor, put Put it into an oven and react at 90°C for 6h; after the reaction, take out the nickel foam sheet, ultrasonically clean the excess sediment on the surface with deionized water, and dry at 60°C ...

Embodiment 2

[0043] A. Use a foamed nickel sheet with a purity of 98wt% as the substrate, cut it into a piece of 10*15cm size, clean it ultrasonically with 30wt% concentrated hydrochloric acid for 50 seconds, then ultrasonically clean it 3 times with deionized water, and clean it once with absolute ethanol. Dry it in a 60°C oven for later use;

[0044] B. Dissolve 58.16gNi(NO 3 ) 2 Prepare 800ml of nickel nitrate solution, then use deionized water to dissolve 18.7gNaOH and 15.5gNa 2 CO 3 Prepare 225ml of alkali solution; put the foamed nickel sheet treated in step A into the nickel nitrate solution, then add the alkali solution drop by drop under stirring until the pH value is 9, then transfer them together to a 1000ml beaker, and seal it with plastic wrap At the mouth of the beaker, stir vigorously in a water bath at 60°C and react for 5 hours. After the reaction, take out the nickel foam sheet and clean it with deionized water ultrasonic waves, put it in an oven, and dry it at 60°C fo...

Embodiment 3

[0048] A. Use a foamed nickel sheet with a purity of 93wt% as the substrate, cut it into a piece of 10*15cm in size, ultrasonically clean it with 36wt% concentrated hydrochloric acid for 50 seconds, then ultrasonically clean it 3 times with deionized water, and then ultrasonically clean it once with absolute ethanol. Dry it in a 60°C oven for later use;

[0049] B. Dissolve 58.1gNi(NO 3 ) 2 Prepare 750ml of nickel nitrate solution, then use deionized water to dissolve 18.67g of NaOH and 15.44g of NaOH 2 CO 3 Prepare 250ml of alkali solution; put the foamed nickel sheet treated in step A into the nickel nitrate solution, then add the alkali solution drop by drop under stirring until the pH value is 8.5, then transfer them together to a 1000ml beaker, and seal it with plastic wrap At the mouth of the beaker, stir vigorously in a water bath at 60°C and react for 5 hours. After the reaction, take out the nickel foam sheet and clean it with deionized water ultrasonic waves, put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com