Catalyst and method for preparing glycine methyl ester and glycine from methyl glycolate by using bimetallic glass fiber layered eutectic

A technology of methyl glycolate and methyl glycine, which is applied to the catalyst for preparing methyl glycine and glycine from methyl glycolate and the field of preparation thereof, can solve the problems such as difficulty in obtaining a zero-valent metal-supported catalyst, and achieve significant economic advantages, Simple separation and purification, simple and efficient process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

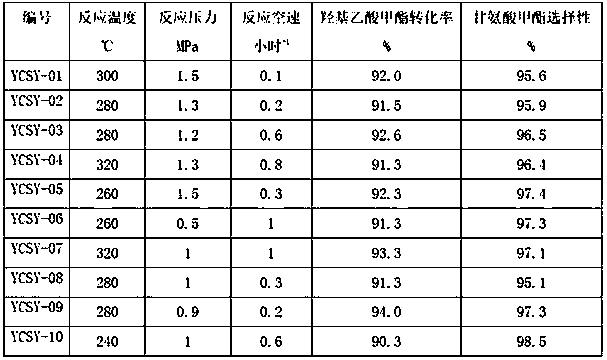

Examples

Embodiment 1

[0024] A bimetallic glass filament layered eutectic catalyst comprises 100 parts by weight, 5 parts of metal cobalt, 1 part of metal nickel, and the rest is vitrified silica carrier.

[0025] The preparation method of the bimetallic glass filament layered eutectic catalyst: take metal cobalt, metal nickel and vitrified silica carrier according to the above ratio, and mix metal cobalt and metal nickel with vitrified silica carrier under nitrogen atmosphere Finally, after heating to 1800°C, centrifuge at a speed of 150r / min for 15 minutes. Due to the high specific gravity, the metal is distributed on the outer layer of the vitrified silica carrier after centrifugation, forming a bimetallic-glass layered eutectic Through the glass filament drawing process, it is prepared into a metal-containing layered glass filament of 2-10 μm, that is, a bimetallic glass filament layered eutectic catalyst is obtained, and the loading of cobalt and nickel metal atoms on the outer surface of the g...

Embodiment 2

[0028] A bimetallic glass filament layered eutectic catalyst comprises 100 parts by weight, 5 parts of metal cobalt, 5 parts of metal nickel, and the rest is vitrified silica carrier.

[0029] The preparation method of the bimetallic glass filament layered eutectic catalyst: take metal cobalt, metal nickel and vitrified silica carrier according to the above ratio, and mix metal cobalt and metal nickel with vitrified silica carrier under nitrogen atmosphere Finally, after heating to 1600°C, centrifuge at a speed of 300r / min for 3 minutes. Due to the high specific gravity, the metal is distributed on the outer layer of the vitrified silica carrier after centrifugation, forming a bimetallic-glass layered eutectic Through the glass filament drawing process, it is prepared into a metal-containing layered glass filament of 2-10 μm, that is, a bimetallic glass filament layered eutectic catalyst is obtained, and the loading of cobalt and nickel metal atoms on the outer surface of the g...

Embodiment 3

[0032] A bimetallic glass filament layered eutectic catalyst comprises 100 parts by weight, 20 parts of metal cobalt, 5 parts of metal nickel, and the rest is vitrified silica carrier.

[0033] The preparation method of the bimetallic glass filament layered eutectic catalyst: take metal cobalt, metal nickel and vitrified silica carrier according to the above ratio, and mix metal cobalt and metal nickel with vitrified silica carrier under nitrogen atmosphere Finally, after heating to 1700°C, centrifuge at a speed of 280r / min for 2 minutes. Due to the high specific gravity, the metal is distributed on the outer layer of the vitrified silica carrier after centrifugation, forming a bimetallic-glass layered eutectic Through the glass filament drawing process, it is prepared into a metal-containing layered glass filament of 2-10 μm, and a bimetallic glass filament layered eutectic catalyst is prepared to realize the loading of cobalt and nickel metal atoms on the outer surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com