Combustion rate regulator for carbon-based zinc oxide composite propellant and low-temperature preparation method thereof

A carbon-based zinc oxide, propellant technology, applied in offensive equipment, gaseous chemical plating, ammonium perchlorate composition, etc., to achieve the effect of excellent burning rate adjustment ability, excellent burning rate adjustment performance, and optimized energy release structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

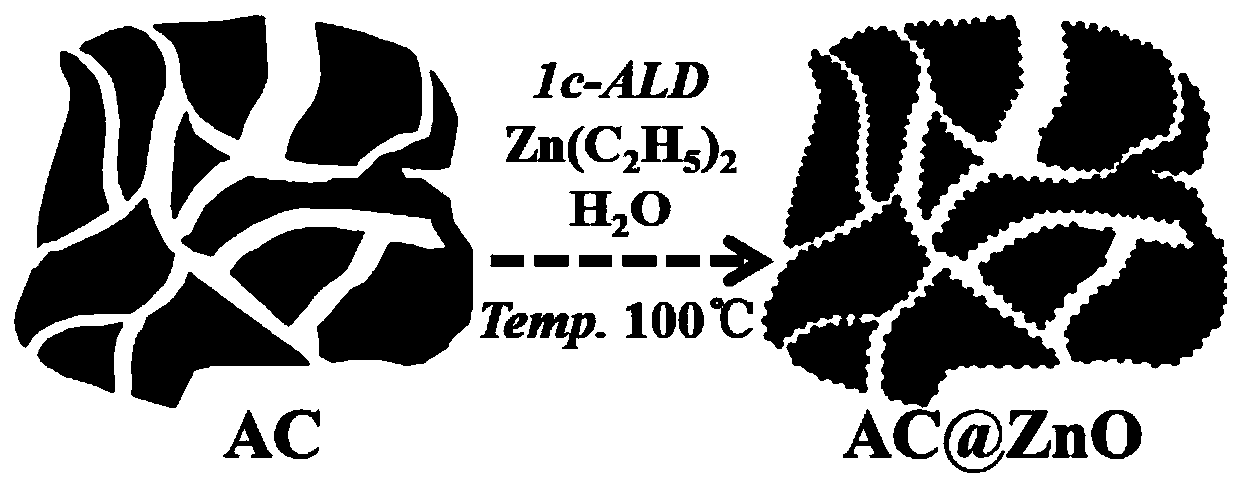

[0037] This embodiment proposes a carbon-based zinc oxide composite propellant burning rate regulator and its low-temperature preparation method. The carbon-based base material used is activated carbon (AC) material with a specific surface area of 1250 square meters per gram. The preparation method specifically includes the following steps :

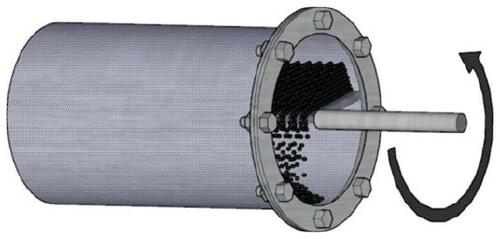

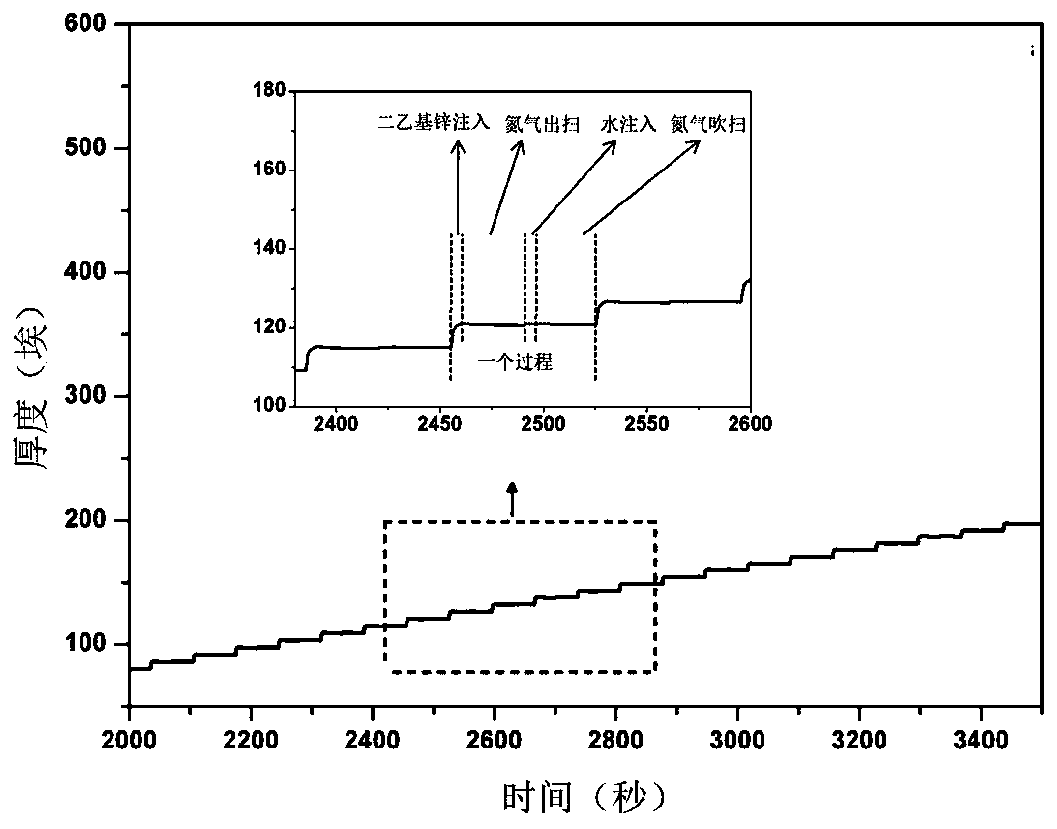

[0038] Step 1, such as figure 1 As shown, the activated carbon is placed in the porous container and then placed in the reaction chamber of the chemical vapor deposition equipment, a quartz crystal microbalance is installed at the sample inlet and outlet of the chemical reaction deposition equipment, and then the sample inlet and outlet of the chemical reaction deposition equipment is closed;

[0039] Step 2, respectively heating the chemical vapor deposition reaction chambers with electric heating wires to keep the temperature at 100°C;

[0040] Step 3. Nitrogen gas with a flow rate of 100 sccm is passed into the reaction chamber fro...

Embodiment 2

[0051] This example proposes a carbon-based zinc oxide composite propellant burning rate regulator and its low-temperature preparation method. The carbon-based base material used is a carbon nanotube (CNT) material with a specific surface area of 820 square meters per gram. The preparation method specifically includes The following steps:

[0052] Step 1. Spread the carbon nanotubes flat on the sample tank and place them in the reaction chamber of the chemical vapor deposition equipment, and then close the sample inlet and outlet of the chemical reaction deposition equipment;

[0053] Step 2, respectively heating the chemical vapor deposition reaction chambers with electric heating wires to keep the temperature at 80°C;

[0054] Step 3. Nitrogen gas with a flow rate of 50 sccm is passed into the reaction chamber from the inlet of the vapor deposition equipment, and a vacuum pump is used at the outlet of the vapor deposition equipment to pump air, so that the vacuum degree in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com