Composite coating layer with hydrophobicity and wear resistance as well as preparation method and application thereof

A composite coating and wear-resistant technology, applied in the field of polymer chemical materials, to achieve the effect of enhancing the microstructure, reducing the possibility of icing, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a composite coating having both hydrophobicity and wear resistance, comprising the following steps:

[0042] 1. Coating preparation

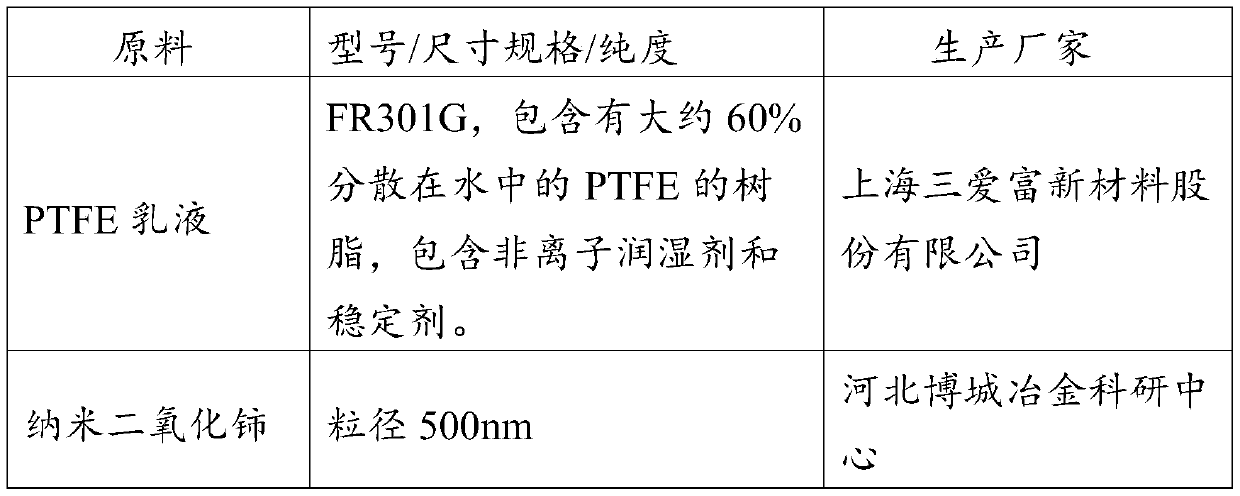

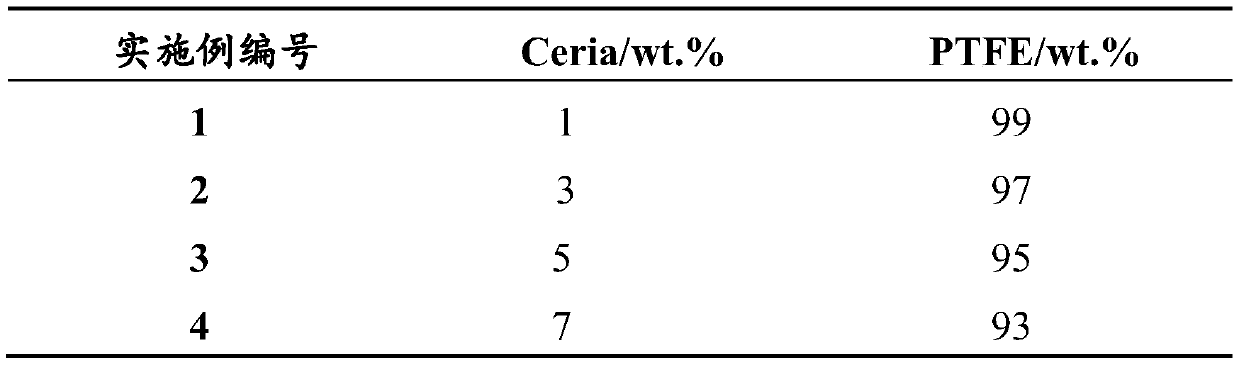

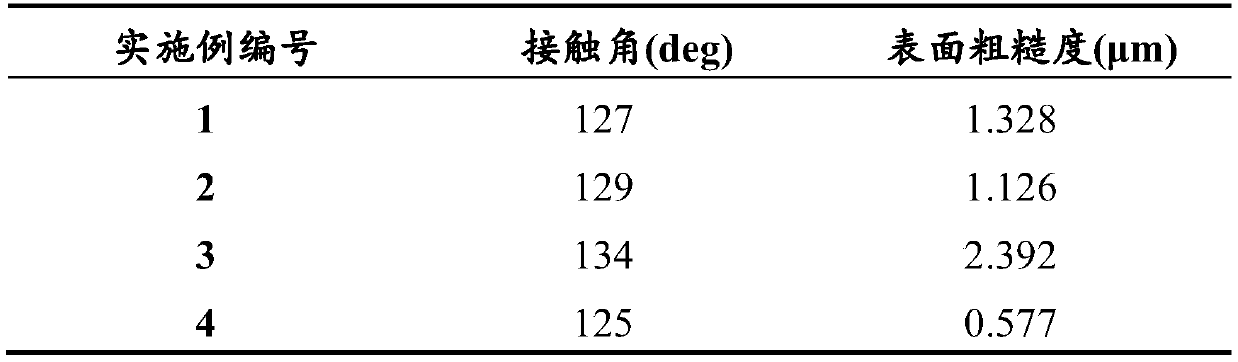

[0043] 165 parts by mass of an aqueous polytetrafluoroethylene emulsion (which contains 99 parts by mass of polytetrafluoroethylene), and 1 part by mass of ceria particles with a particle diameter of 500 nm were dispersed for 20 minutes until uniform using a sand mill. The list of ingredients is shown in Table 1 and Table 2.

[0044] 2. Workpiece surface pretreatment

[0045] In order to make the workpiece coating have sufficient surface adhesion, first use an organic solvent to dissolve the grease on the surface of the workpiece and heat it to about 400°C to volatilize it, and then use sandblasting to clean the surface of the workpiece and obtain a certain roughness on the surface to improve The ability of the coating to bond to the surface of the workpiece.

[0046] 3. Spraying

[0047] Put the paint into the ...

Embodiment 2

[0053] A method for preparing a composite coating having both hydrophobicity and wear resistance, comprising the following steps:

[0054] 1. Coating preparation

[0055] 162 parts by mass of an aqueous emulsion of polytetrafluoroethylene (containing 97 parts by mass of polytetrafluoroethylene) and 3 parts by mass of ceria particles with a particle diameter of 500 nm were dispersed for 20 minutes until uniform using a sand mill. The list of ingredients is shown in Table 1 and Table 2.

[0056] 2. Workpiece surface pretreatment

[0057] In order to make the workpiece coating have sufficient surface adhesion, first use an organic solvent to dissolve the grease on the surface of the workpiece and heat it to about 400°C to volatilize it, and then use sandblasting to clean the surface of the workpiece and obtain a certain roughness on the surface to improve The ability of the coating to bond to the surface of the workpiece.

[0058] 3. Spraying

[0059] Put the paint into the A...

Embodiment 3

[0065] A method for preparing a composite coating having both hydrophobicity and wear resistance, comprising the following steps:

[0066] 1. Coating preparation

[0067] 158 parts by mass of polytetrafluoroethylene emulsion (which contains 95 parts by mass of polytetrafluoroethylene) and 5 parts by mass of ceria particles with a particle diameter of 500 nm were dispersed for 20 minutes until uniform using a sand mill. The list of ingredients is shown in Table 1 and Table 2.

[0068] 2. Workpiece surface pretreatment

[0069] In order to make the workpiece coating have sufficient surface adhesion, first use an organic solvent to dissolve the grease on the surface of the workpiece and heat it to about 400°C to volatilize it, and then use sandblasting to clean the surface of the workpiece and obtain a certain roughness on the surface to improve The ability of the coating to bond to the surface of the workpiece.

[0070] 3. Spraying

[0071] Put the paint into the ANESTIWATA ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com