Coating for melamine veneer cabinet and coating method thereof

A melamine and skin-coating technology, which is applied to polyester coatings, devices for coating liquid on the surface, coatings, etc., can solve problems such as poor adhesion, unreachable hardness, and easy yellowing of the coating, and achieve excellent durability. Yellowing performance, enhanced adhesion, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a paint for melamine skinned cabinets, including a primer, a white primer, a color trimming topcoat, and a clear topcoat, which are sequentially applied from bottom to top on the surface of the melamine skinned cabinetry, and the primer and the color trimming topcoat They are all two-component acrylic polyurethane paints; among them, the primer and color-fixing topcoat can be purchased or self-made.

[0054] The primer and color-fixing topcoat in this embodiment are both self-made two-component acrylic polyurethane paints according to conventional preparation methods, and the specific raw materials are as follows:

[0055] The primer consists of the following raw materials in parts by weight: 40-60 parts of hydroxyl acrylic resin I, 1-10 parts of cellulose ester I, 40-60 parts of solvent I, 0.01-0.05 parts of leveling agent I, 0.05-0.2 Parts of drying accelerator I, 0.15-1 parts of auxiliary I, 40-60 parts of polyisocyanate I, 40-60 parts of diluent ...

Embodiment 2-5

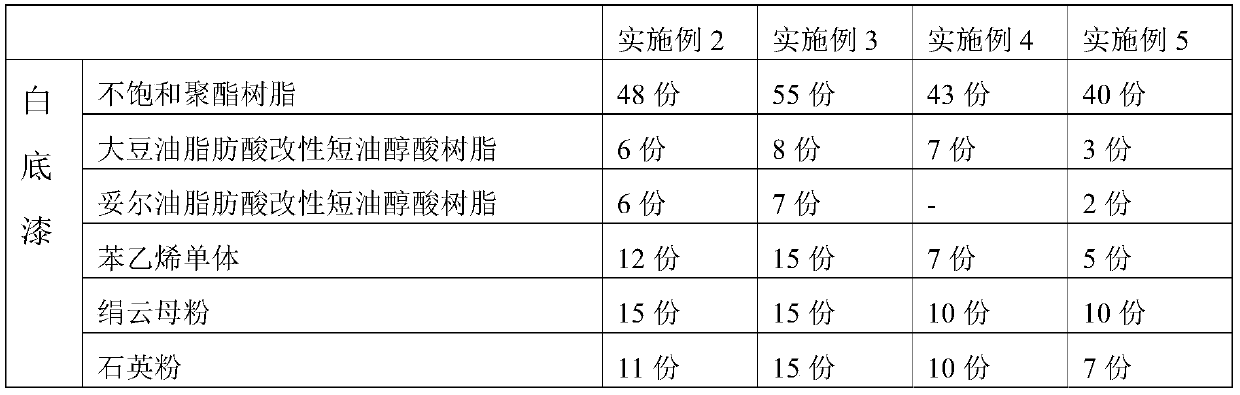

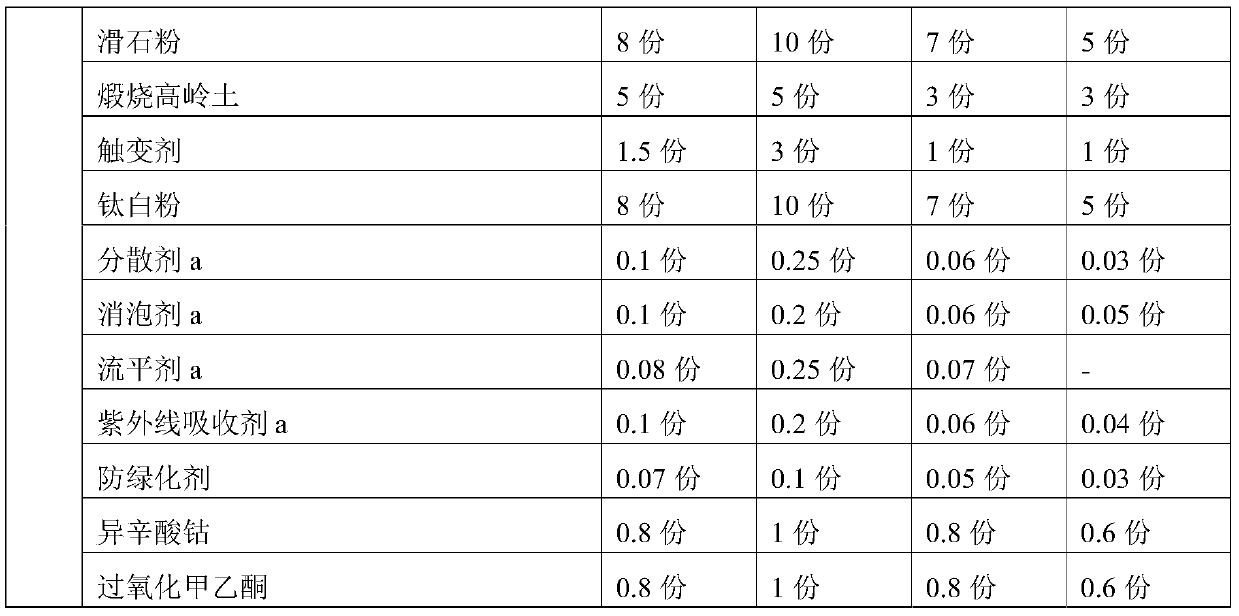

[0089] The raw material composition and preparation method of the white primer of Examples 2-5 are basically the same as those of Example 1, and the difference lies in:

[0090] Table 1 White primer ratio of Example 2-5

[0091]

[0092]

[0093] Among them, the unsaturated polyester resin of Example 2 has a styrene content of 23% and a viscosity of 1700 CPS. The unsaturated polyester resin of Example 3 has a styrene content of 25% and a viscosity of 1600 CPS. The unsaturated polyester resin of Example 4 has a styrene content of 21% and a viscosity of 2000 CPS. The unsaturated polyester resin of Example 5 has a styrene content of 21% and a viscosity of 2000 CPS.

Embodiment 6-9

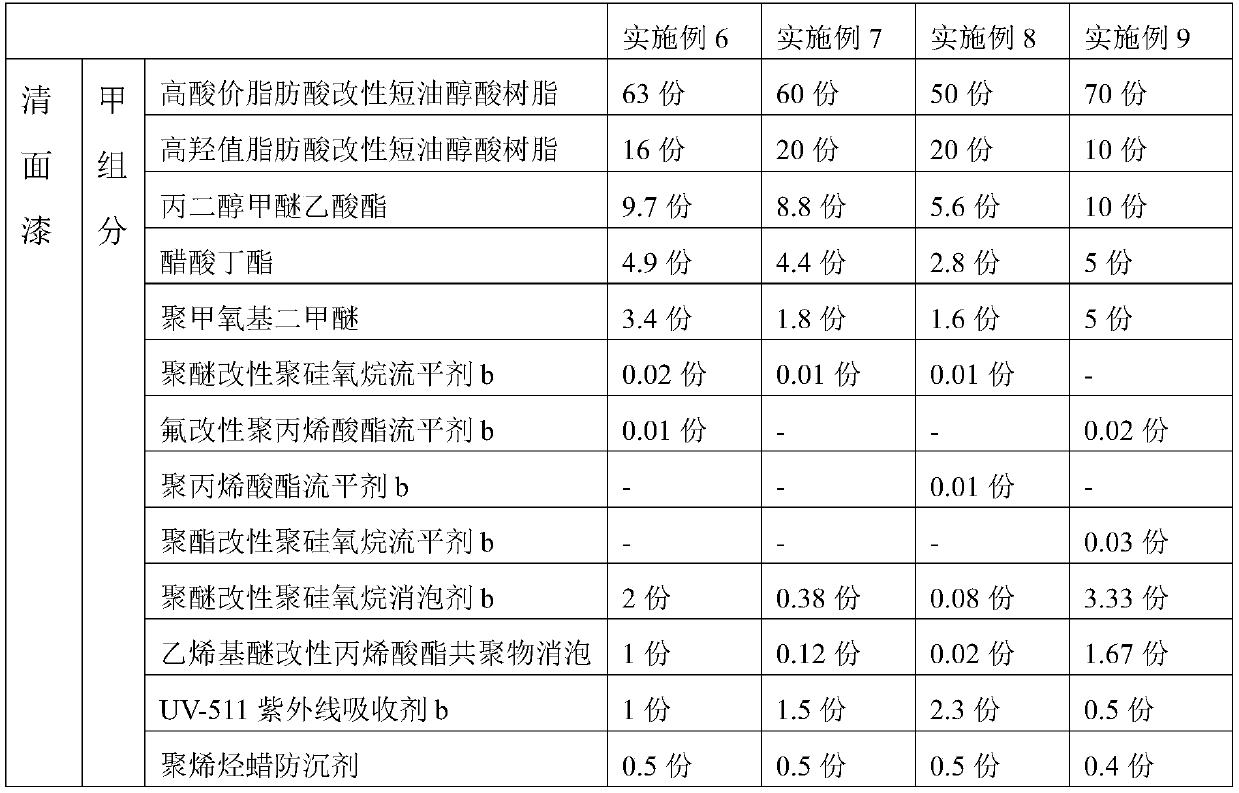

[0095] The raw material composition and preparation method of the clear topcoat of Examples 6-9 are basically the same as those of Example 1, and the difference lies in:

[0096] Table 2 The ratio of clear topcoats in Examples 6-9

[0097]

[0098]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap