Medium-strength super-hard aluminum alloy and manufacturing process thereof

A hard aluminum alloy and manufacturing process technology, which is applied in the field of aluminum alloy, can solve the problems of failing to realize the short process of lightweight processing of auto parts, and achieve the effect of enhancing the solid solution effect, increasing the strength, and improving the ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

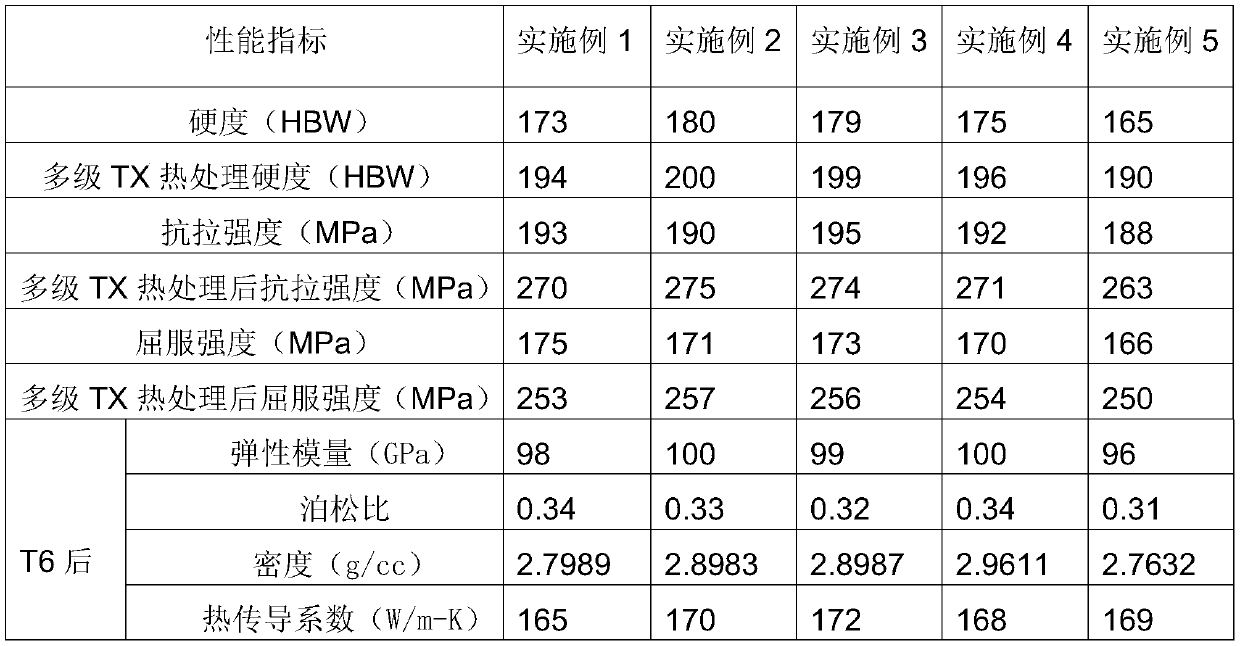

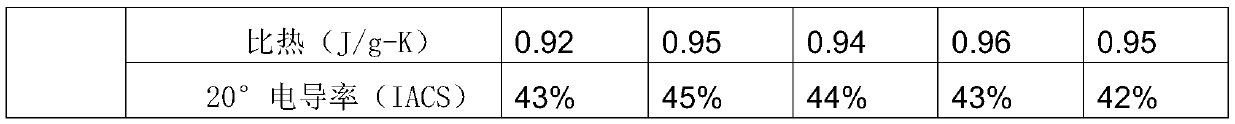

Examples

Embodiment 1

[0032] The medium-strength superhard aluminum alloy is composed of the following components in terms of mass percentage: Si 15%, Cu 12%, Zn 4%, Fe 0.5%, Mg 0.5%, Ni 0.4%, Mn 0.3%, Co 0.2%, La0.1%, Al remainder.

[0033] The manufacturing process of the medium-strength superhard aluminum alloy includes batching, smelting, and casting in sequence;

[0034] Ingredients: According to the formula, the ingredients are washed with alkaline solution until the defects such as alumina and slag on the surface are removed, and then baked to remove the contained water

[0035] Described smelting, comprises the following steps:

[0036] (1) Aluminum: the matrix is placed in a natural gas furnace at a temperature of 750°C, and an intermediate alloy is added, and alloyed in the following order: Al-Si alloy, Cu-Zn alloy, Fe-Ni alloy, Al-Mg alloy, Co-La alloy;

[0037] (2) Detection: get the above-mentioned melt in the natural gas furnace and carry out spectral test to obtain the informati...

Embodiment 2

[0045] The medium-strength superhard aluminum alloy is composed of the following components in terms of mass percentage: 16% Si, 12% Cu, 5% Zn, 0.7% F, 0.5% Mg, 0.5% Ni, 0.4% Mn, 0.3% Co %, La0.2%, Al balance.

[0046] The manufacturing process of the medium-strength superhard aluminum alloy includes batching, smelting, and casting in sequence;

[0047] Ingredients: According to the formula, the ingredients are washed with alkaline solution until the defects such as alumina and slag on the surface are removed, and then baked to remove the contained water

[0048] Described smelting, comprises the following steps:

[0049] (1) Aluminum: the matrix is placed in a natural gas furnace at a temperature of 760°C, and an intermediate alloy is added, and alloyed in the following order: Al-Si alloy, Cu-Zn alloy, Fe-Ni alloy, Al-Mg alloy, Co-La alloy;

[0050] (2) Detection: get the above-mentioned melt in the natural gas furnace and carry out spectral test to obtain the informatio...

Embodiment 3

[0058] The medium-strength superhard aluminum alloy is composed of the following components in terms of mass percentage: Si 18%, Cu 10%, Zn3%, Fe 0.8%, Mg 0.6%, Ni-0.6%, Mn 0.5%, Co 0.3% , La0.4%, Al balance.

[0059] The manufacturing process of the medium-strength superhard aluminum alloy includes batching, smelting, and casting in sequence;

[0060] Ingredients: According to the formula, the ingredients are washed with alkaline solution until the defects such as alumina and slag on the surface are removed, and then baked to remove the contained water

[0061] Described smelting, comprises the following steps:

[0062] (1) Aluminum: the matrix is placed in a natural gas furnace at a temperature of 730°C, and an intermediate alloy is added, and alloyed in the following order: Al-Si alloy, Cu-Zn alloy, Fe-Ni alloy, Al-Mg alloy, Co-La alloy;

[0063] (2) Detection: get the above-mentioned melt in the natural gas furnace and carry out spectral test to obtain the information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com