Preparation and lossless recovery method of inlaid sample

A recovery method and thermosetting technology, which are applied in the preparation of test samples, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of acetone being toxic, flammable, and scarce of samples, and achieve a simple recovery process, Guaranteed integrity and strong design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

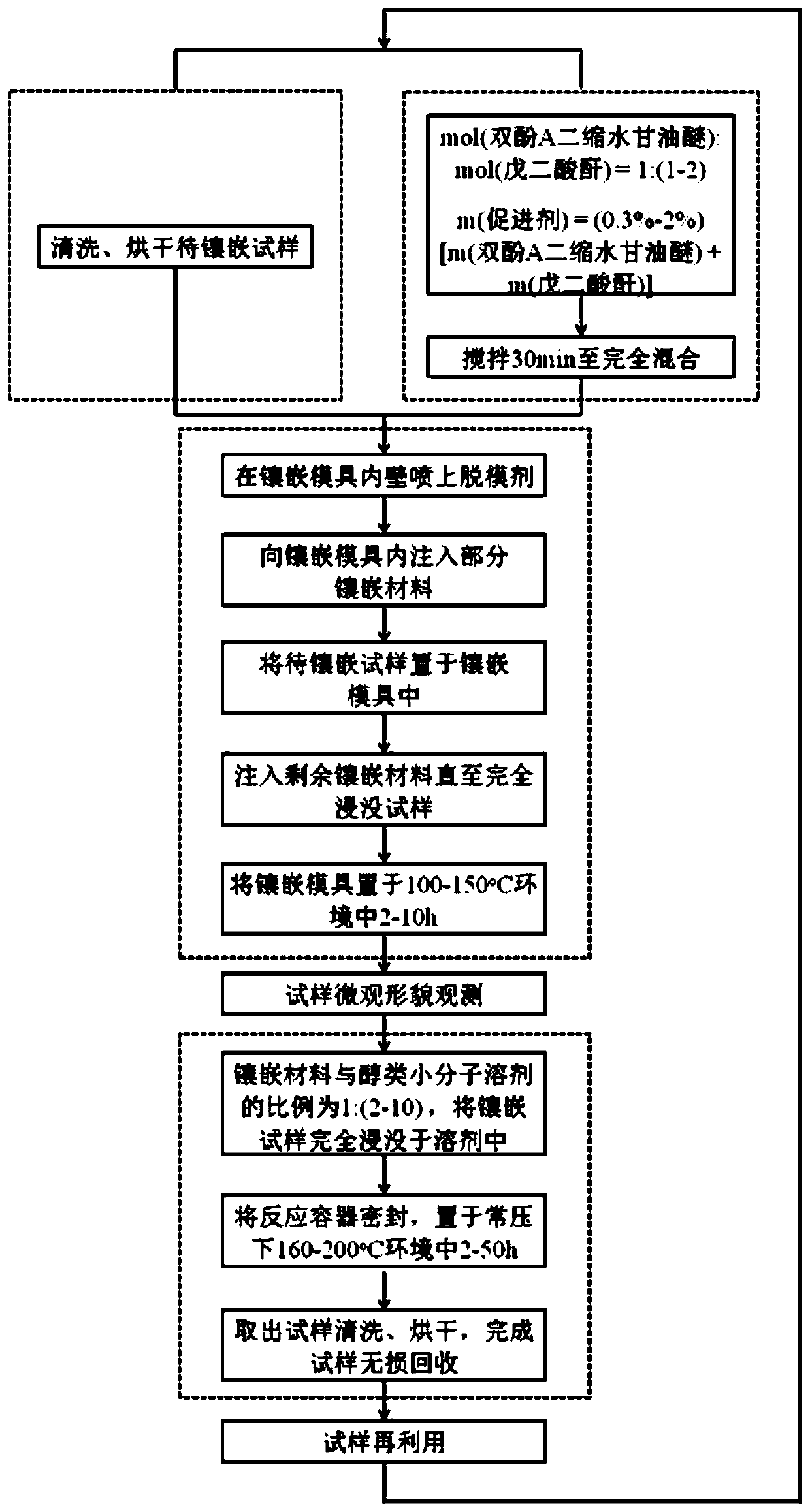

Method used

Image

Examples

Embodiment 1

[0031] Mix bisphenol A diglycidyl ether and glutaric anhydride uniformly at a molar ratio of 1:1, and then add (2,4,6)-tris(dimethylaminomethyl)phenol at 0.3% of the mass sum of the two , and mix the three evenly to obtain the prepared mosaic material.

[0032] Spray release agent on the inner wall of the mosaic mold, then slowly inject part of the prepared mosaic material into the mosaic mold, then place the cleaned and dried sample to be mosaic in the mosaic mold, and then slowly inject the remaining mosaic material Until the sample is completely submerged; place the mosaic mold in an oven at 130°C under normal pressure for 6 hours to ensure that the mosaic material is completely cured.

[0033] After the observation of the microscopic morphology of the sample is completed, according to the mass ratio of the mounting material and the alcohol small molecule solvent of 1:4, the mounting sample is completely immersed in ethylene glycol, and then the reaction vessel is sealed and ...

Embodiment 2

[0035] Mix bisphenol A diglycidyl ether and glutaric anhydride evenly at a molar ratio of 1:2, and then add (2,4,6)-tris(dimethylaminomethyl)phenol at 2% of the mass sum of the two , and mix the three evenly to obtain the prepared mosaic material.

[0036] Spray release agent on the inner wall of the mosaic mold, then slowly inject part of the prepared mosaic material into the mosaic mold, then place the cleaned and dried sample to be mosaic in the mosaic mold, and then slowly inject the remaining mosaic material Until the sample is completely submerged; place the mosaic mold in an oven at 150°C under normal pressure for 2 hours to ensure that the mosaic material is completely cured.

[0037] After the observation of the microscopic morphology of the sample is completed, according to the mass ratio of the mounting material and the alcohol small molecule solvent of 1:4, the mounting sample is completely immersed in ethylene glycol, and then the reaction vessel is sealed and pla...

Embodiment 3

[0039] Mix bisphenol A diglycidyl ether and glutaric anhydride uniformly at a molar ratio of 1:1, and then add (2,4,6)-tris(dimethylaminomethyl)phenol at 2% of the mass sum of the two , and mix the three evenly to obtain the prepared mosaic material.

[0040] Spray release agent on the inner wall of the mosaic mold, then slowly inject part of the prepared mosaic material into the mosaic mold, then place the cleaned and dried sample to be mosaic in the mosaic mold, and then slowly inject the remaining mosaic material Until the sample is completely submerged; place the mosaic mold in an oven at 130°C under normal pressure for 6 hours to ensure that the mosaic material is completely cured.

[0041] After the observation of the microscopic morphology of the sample is completed, according to the mass ratio of the mounting material and the alcohol small molecule solvent of 1:4, the mounting sample is completely immersed in ethylene glycol, and then the reaction vessel is sealed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com