Triple smelting process of difficult-to-deform nickel-based high-temperature alloy GH4151

A nickel-based superalloy, GH4151 technology, applied in the field of hot processing, can solve the problem of low degree of dendrite segregation, and achieve the effect of low degree of dendrite segregation, reduced sulfur and inclusion content, and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

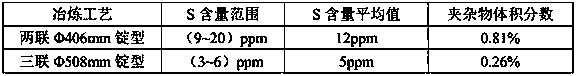

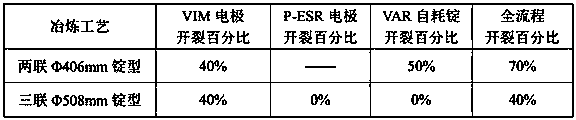

[0034] Example 1. A triple smelting process of a difficult-to-deform nickel-based superalloy GH4151

[0035] This example mainly describes a triple smelting process of a hard-to-deform nickel-based superalloy GH4151. The triple smelting process is specifically vacuum induction furnace smelting (VIM) + protective atmosphere electroslag remelting (P-ESR) + vacuum Consumable remelting (VAR) smelting. The diameter of alloy ingots for vacuum induction furnace smelting (VIM) is 360mm, the diameter of alloy ingots for protective atmosphere electroslag remelting (P-ESR) is 450mm, and the diameter of alloy ingots for vacuum consumable remelting (VAR) is 508mm.

[0036] The process flow of vacuum induction melting (VIM) includes the following steps:

[0037] Step 1.1: According to the composition requirements of the GH4151 alloy, weigh the raw materials. The weight percentage (wt.%) of each raw material is: C0.04, Co 14.0, Cr 10.0, Mo 4.0, W 2.5, V 0.40, Ti 2.50, Al 3.5, Nb 3.0, S=0.0...

Embodiment 2

[0065] Example 2: A triple smelting process of a hard-to-deform nickel-based superalloy GH4151

[0066] This example mainly describes a triple smelting process of a hard-to-deform nickel-based superalloy GH4151. The triple smelting process is specifically vacuum induction furnace smelting (VIM) + protective atmosphere electroslag remelting (P-ESR) + vacuum Consumable remelting (VAR) smelting. The diameter of alloy ingots for vacuum induction furnace smelting (VIM) is 350mm, the diameter of alloy ingots for protective atmosphere electroslag remelting (P-ESR) is 450mm, and the diameter of alloy ingots for vacuum consumable remelting (VAR) is 508mm.

[0067] The process flow of vacuum induction melting (VIM) includes the following steps:

[0068] Step 1.1: According to the composition requirements of the GH4151 alloy, weigh the raw materials. The weight percentage (wt.%) of each raw material is: C0.08, Co 16.0, Cr 12.0, Mo 5.0, W 3.5, V 0.80, Ti 3.10, Al 4.0, Nb 3.5, S=0.0005, ...

Embodiment 3

[0096] Example 3: A triple smelting process of a hard-to-deform nickel-based superalloy GH4151

[0097] This example mainly describes a triple smelting process of a hard-to-deform nickel-based superalloy GH4151. The triple smelting process is specifically vacuum induction furnace smelting (VIM) + protective atmosphere electroslag remelting (P-ESR) + vacuum Consumable remelting (VAR) smelting. The diameter of the alloy ingot for vacuum induction furnace smelting (VIM) is 340mm, the diameter of alloy ingot for protective atmosphere electroslag remelting (P-ESR) is 430mm, and the diameter of alloy ingot for vacuum consumable remelting (VAR) is 508mm.

[0098] The process flow of vacuum induction melting (VIM) includes the following steps:

[0099] Step 1.1: According to the composition requirements of GH4151 alloy, weigh the raw materials. The weight percentage (wt.%) of each raw material is: C0.07, Co 15.0, Cr 11.0, Mo 4.5, W 3, V 0.50, Ti 2.70, Al 3.7, Nb 3.2, S=0.0001, Ni in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com