Desulfurization and denitration environment-friendly treatment method

A technology for desulfurization, denitrification and environmental protection treatment, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as long consumption time, difficult treatment, poor living conditions, etc., to optimize the preparation process, increase the treatment process, The effect of improving desulfurization and denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

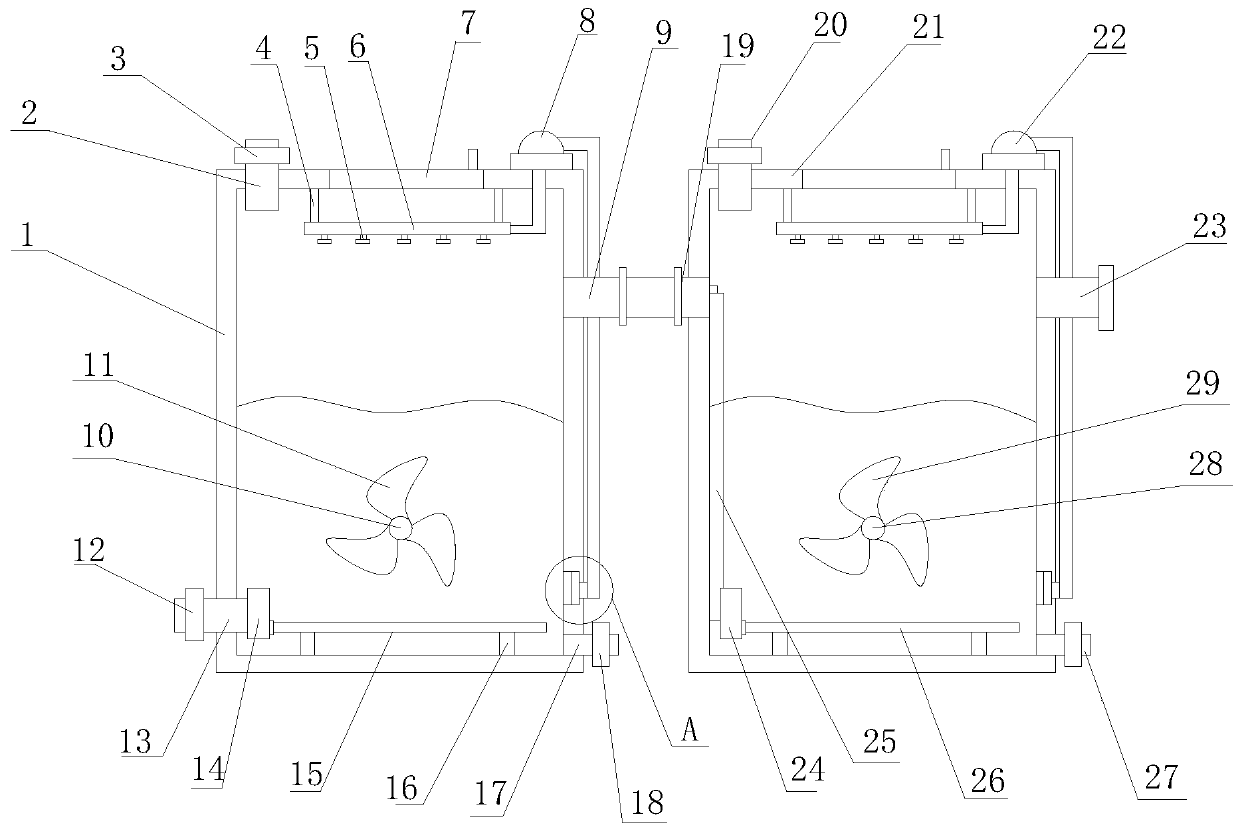

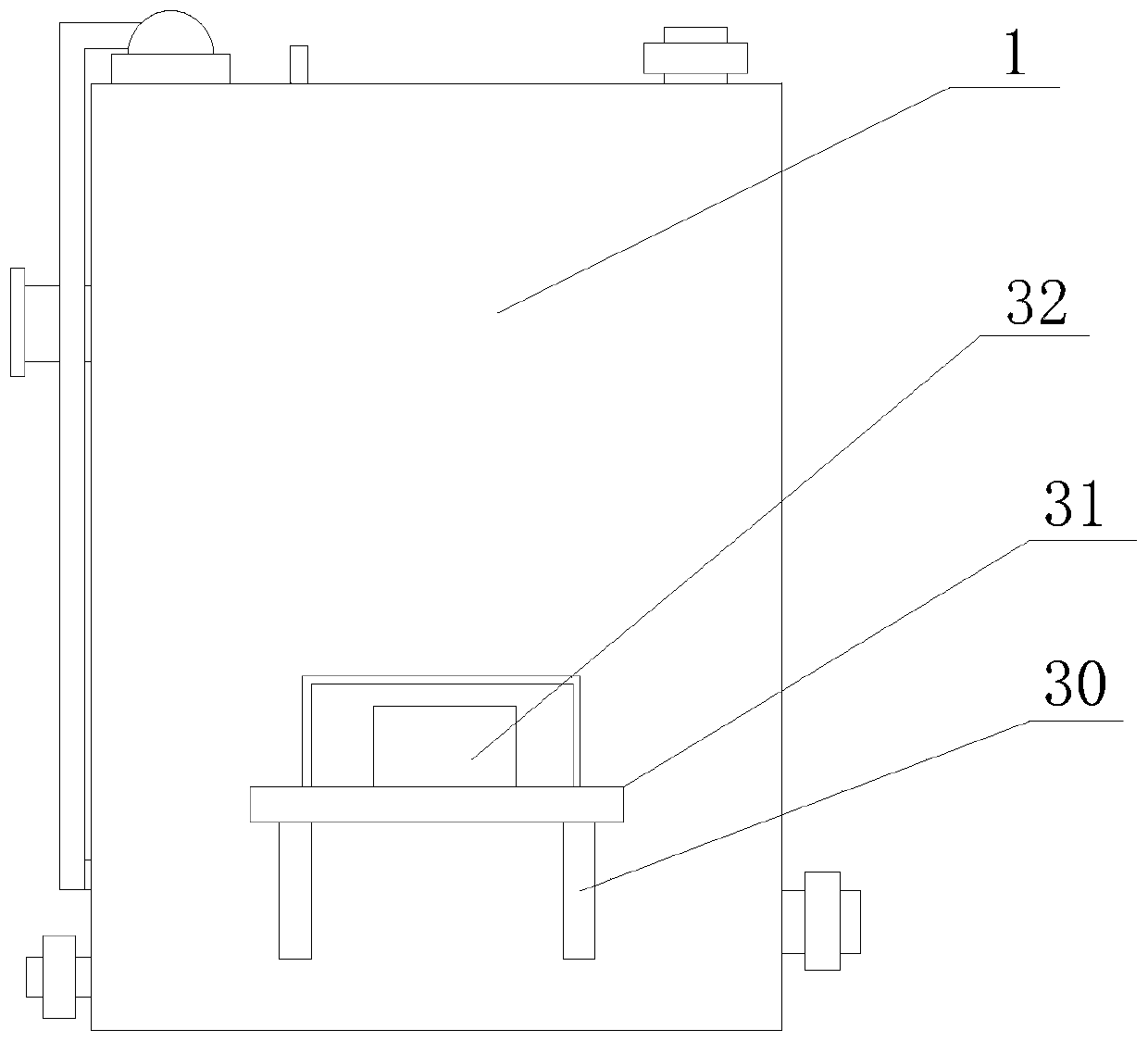

[0035] see Figure 1-4 , the present invention provides a technical solution: a desulfurization and denitrification environmental protection treatment method, comprising the following steps:

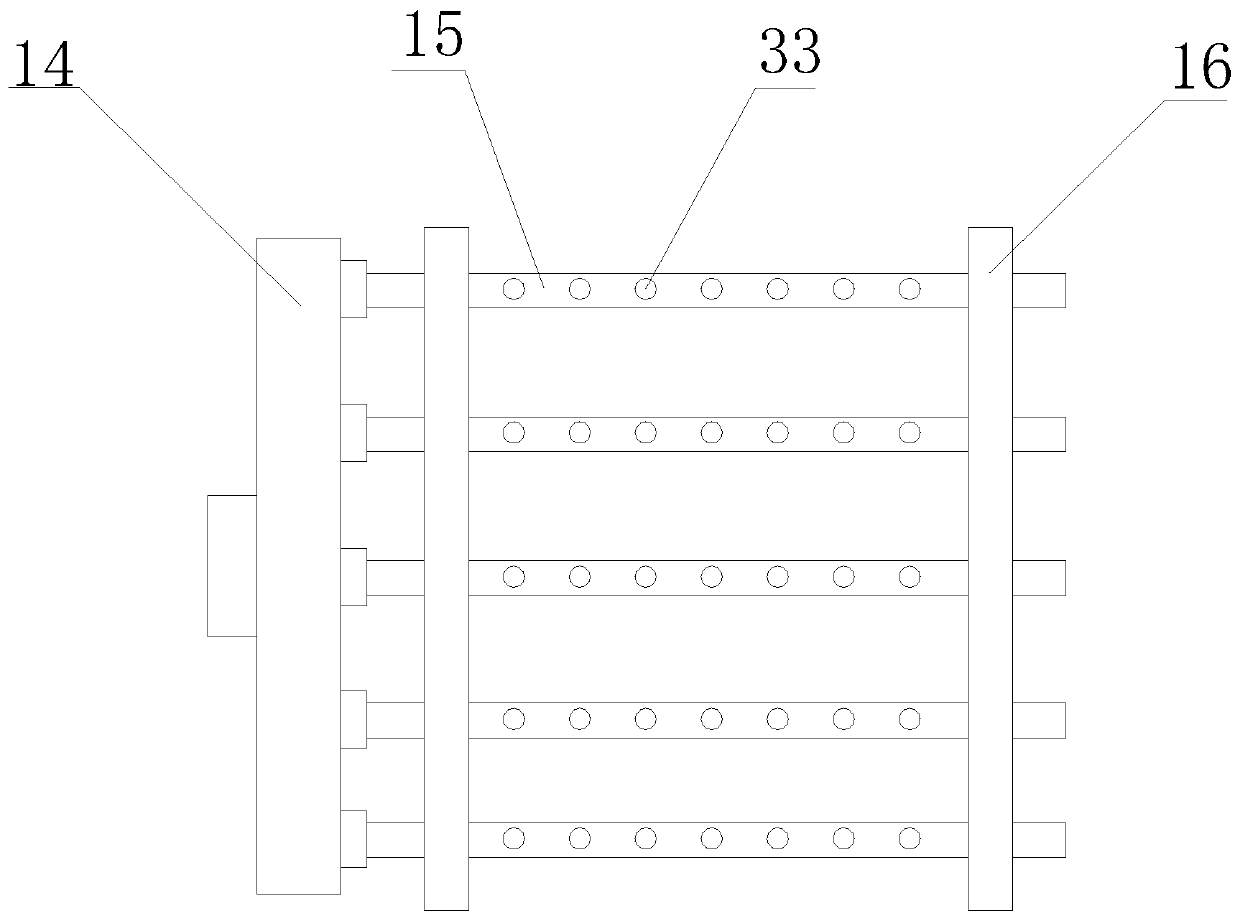

[0036] 1) The flue gas enters the pipe from the air inlet 1 and emerges from the exhaust holes at the bottom of the multiple exhaust pipes fixedly installed on the right side of the pipe 1, and the many smoke bubbles that emerge enter the interior of the desulfurization tank in the desulfurization solvent;

[0037] 2) The stirring motor drives the stirring blade on the stirring shaft to stir the desulfurization solvent inside the desulfurization tank, so as to speed up the contact between the flue gas bubbles and the desulfurization solvent to produce a reaction;

[0038] 3) The desulfurization solvent extracted by the water pump 1 is sprayed from multiple spray heads and contacts the bubbles floating out of the desulfurization solvent in the air for further desulfurization. After the f...

Embodiment 2

[0045] In embodiment 1, the desulfurization solvent and the denitration solvent contain a desulfurization and denitration catalyst, and the preparation method of the desulfurization and denitration catalyst comprises the following steps:

[0046] S1 Add 10wt% activated carbon powder and 10wt% NY molecular sieve to attapulgite clay powder, add acetic acid and stir, extrude and form, dry and roast at 350°C for 2 hours under nitrogen protection, and grind to make a composite carrier;

[0047] S2 Send the composite carrier into the atmospheric pressure low temperature plasma device, make the composite carrier at the jet outlet of the atmospheric pressure low temperature plasma, pass the gas medium into the atmospheric pressure low temperature plasma device, apply the working voltage, form the plasma jet, and control the atmospheric pressure low temperature plasma The moving speed of the injection outlet of the plasma device is 10mm / s, so that the plasma jet is sprayed on the compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com