High-heat-resistance low-dielectric copper-clad plate and preparation method thereof

A copper clad laminate and low dielectric technology, which is applied in the field of high heat resistance and low dielectric copper clad laminate and its preparation, can solve the problems of poor heat resistance and dielectric properties, and achieve the effect of reducing dielectric property and increasing heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A high heat-resistant and low-dielectric copper-clad laminate, with inverted copper foils on both sides of the copper-clad laminate, and three glass fiber cloth-based prepregs in the middle, each layer is bonded with epoxy resin glue, epoxy resin glue The solution is composed of the following components by weight: 10 parts of brominated epoxy resin with a bromine content of 12%, 15 parts of trifunctional epoxy resin, 15 parts of polystyrene resin, and 8 parts of polyimide resin with a number average molecular weight of 2000. 20 parts, 20 parts of bisphenol A diphenyl ether type bismaleimide, 30 parts of benzoxazine, 0.5 part of 2-methylimidazole, 15 parts of molten spherical silicon with a particle size of 5 μm and 100 parts of DMF;

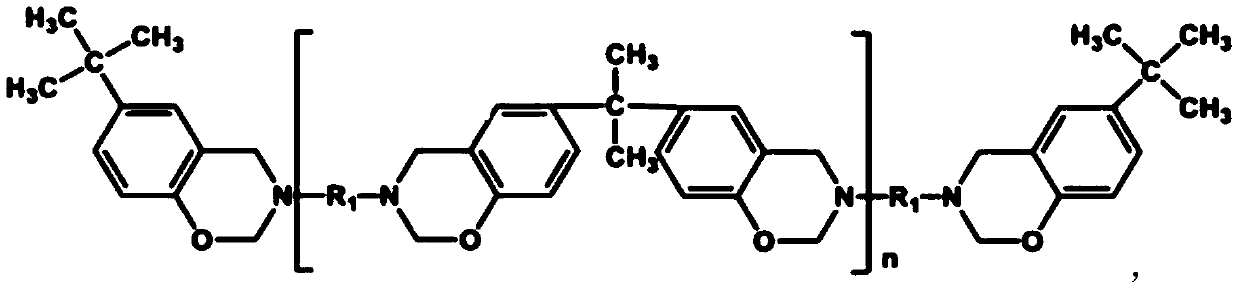

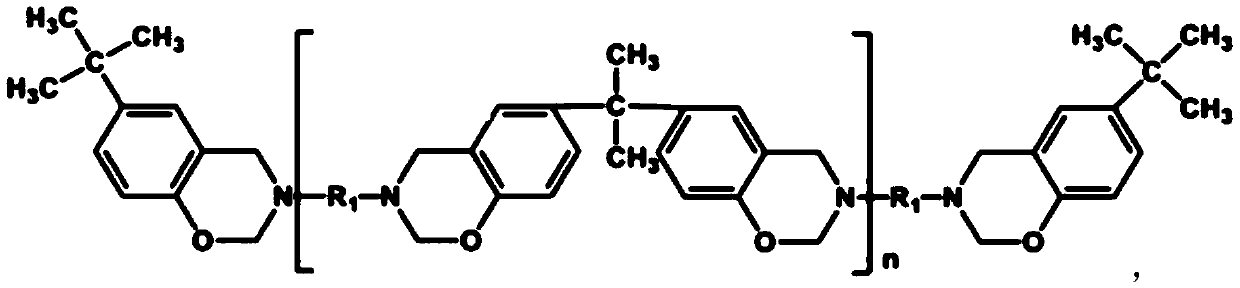

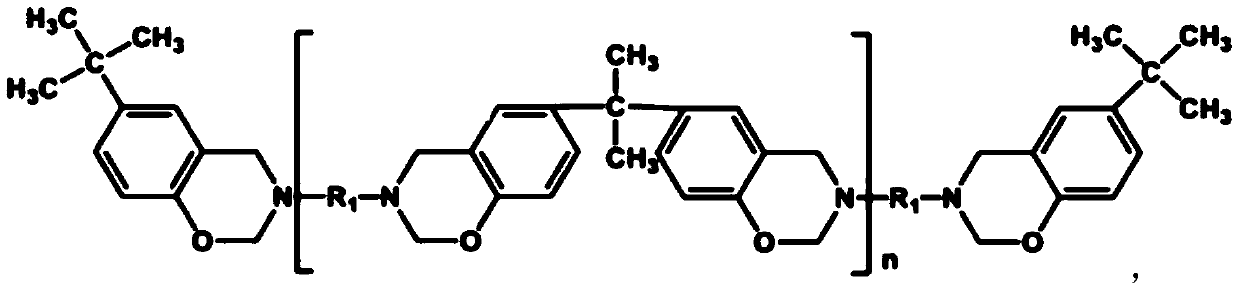

[0014] Among them, the epoxy equivalent of the trifunctional epoxy is 150g / eq, and the softening point is 50°C; the polystyrene resin viscosity is 1000cps (40°C), the vinyl content is 10wt%, and the styrene content is 30wt%; benzoxazine Ha...

Embodiment 2

[0019] A high heat-resistant and low-dielectric copper-clad laminate, with inverted copper foils on both sides of the copper-clad laminate, and four glass fiber paper-based prepregs in the middle, each layer is bonded with epoxy resin glue, epoxy resin glue The solution is composed of the following components by weight: 20 parts of bisphenol A type brominated epoxy with a bromine content of 51%, 12 parts of trifunctional epoxy, 10 parts of polystyrene resin, polyimide with a number average molecular weight of 1000 11 parts of amine resin, 15 parts of bisphenol A diphenyl ether type bismaleimide, 20 parts of benzoxazine, 0.25 parts of 2-ethyl, 4-methylimidazole, molten spherical silicon with a particle size of 0.1 μm 25 parts and 65 parts of toluene;

[0020] Wherein, the epoxy equivalent of trifunctional epoxy is 180g / eq, and softening point is 80 ℃; Polystyrene resin viscosity is 10000cps (40 ℃), vinyl content is 15wt%, and styrene content is 25wt%; Azines have the following...

Embodiment 3

[0025] A high heat-resistant low-dielectric copper-clad laminate, with copper foil on both sides of the copper-clad laminate, and five cotton cloth-based prepregs in the middle, each layer is bonded with epoxy resin glue, and the epoxy resin glue consists of the following weight The composition of parts: 30 parts of brominated epoxy resin with bromine content of 60%, 10 parts of trifunctional epoxy resin, 5 parts of polystyrene resin, 15 parts of polyimide resin with number average molecular weight of 500, bisphenol A: 10 parts of diphenyl ether type bismaleimide, 15 parts of benzoxazine, 0.05 part of 2-phenylimidazole, 35 parts of molten spherical silicon and 30 parts of butanone with a particle diameter of 2.5 μm;

[0026] Wherein, the epoxy equivalent of the trifunctional epoxy is 200g / eq, and the softening point is 110°C; the polystyrene resin viscosity is 20000cps (40°C), the vinyl content is 20wt%, and the styrene content is 20wt%; Azines have the following molecular for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com