Rhodium oxide-nano porous nickel composite electrode capable of detecting formaldehyde and preparation method thereof

A nanoporous nickel and composite electrode technology, which is applied to the electrochemical variables of materials, electrolytic inorganic material coatings, air quality improvement, etc., can solve the problems of inaccurate detection of formaldehyde, the influence of formaldehyde sensors, and insufficient sensitivity, so as to avoid the interference of humidity and potential drift phenomenon, improve sensitivity and response speed, and solve the effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

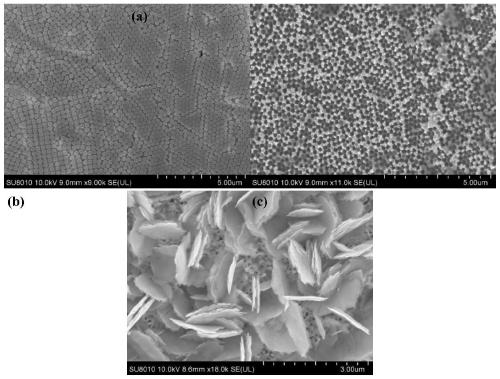

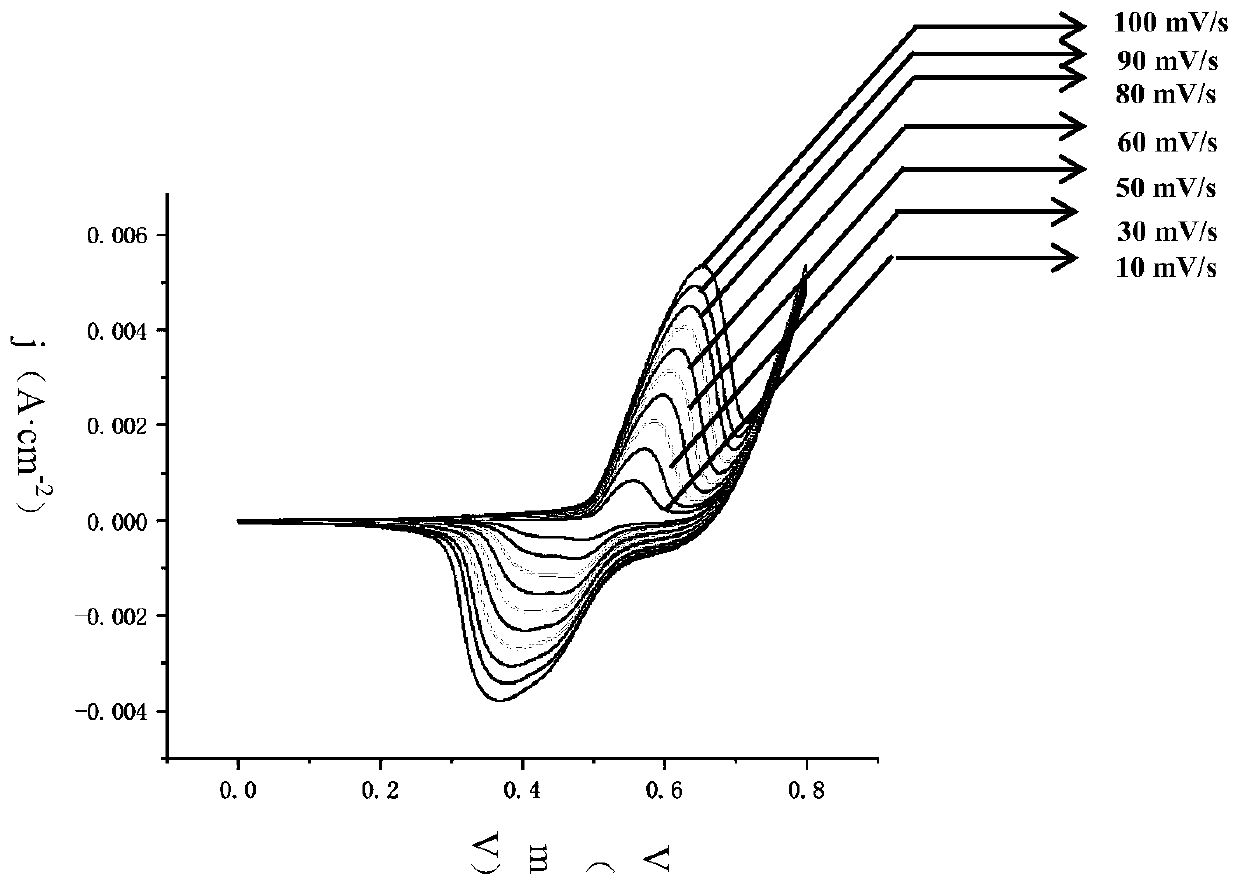

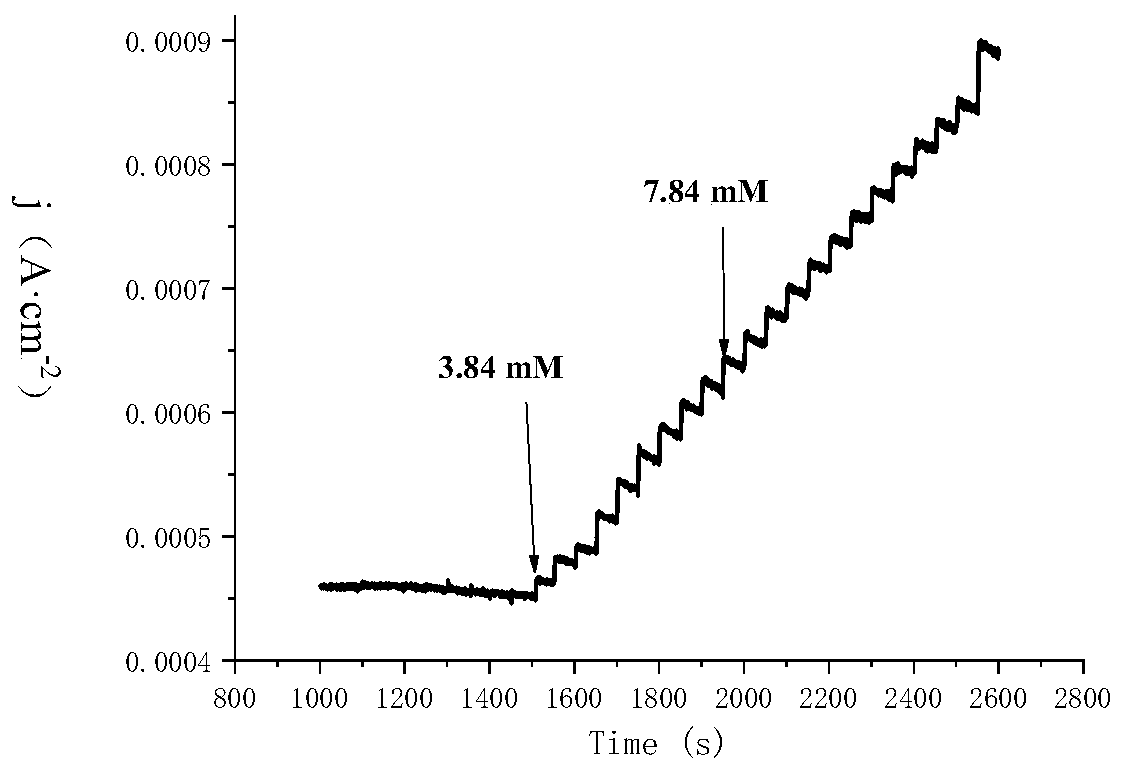

[0044] Preparation of rhodium oxide-nanoporous nickel composite electrode:

[0045] (1) Preparation of porous nickel: adopt template method to prepare nanoporous nickel, concrete method is: first the polystyrene microsphere that diameter is 200-300nm is dispersed in deionized water with the mass concentration of 1-5wt%, forms stable suspension. Using polyimide copper-clad laminate as the working electrode and platinum mesh as the counter electrode, electrophoretic deposition was carried out in the polystyrene microsphere emulsion prepared above. The electrodeposition voltage was 3V and the time was 10min to obtain the polystyrene microsphere template. . Then configure an electrodeposition nickel plating solution, specifically 1.0M nickel sulfamate tetrahydrate, 0.02M nickel chloride and 0.3M boric acid. The polystyrene microsphere template is used as the working electrode, the platinum sheet is used as the counter electrode, and the current density is set at 15.0mA / cm 2 , t...

Embodiment 2

[0048] Preparation of rhodium oxide-nanoporous nickel composite electrode:

[0049] (1) Preparation of porous nickel: adopt template method to prepare nanoporous nickel, concrete method is: first the polystyrene microsphere that diameter is 200-300nm is dispersed in deionized water with the mass concentration of 1-5wt%, forms stable suspension. Using polyimide copper-clad laminate as the working electrode and platinum mesh as the counter electrode, electrophoretic deposition was carried out in the polystyrene microsphere emulsion prepared above. The voltage of electrodeposition was 5V and the time was 5min to obtain the polystyrene microsphere template. . Then configure an electrodeposition nickel plating solution, specifically 1.5M nickel sulfamate tetrahydrate, 0.05M nickel chloride and 0.6M boric acid. The polystyrene microsphere template is used as the working electrode, the platinum sheet is used as the counter electrode, and the current density is set at 10.0mA / cm 2 ,...

Embodiment 3

[0052] Preparation of rhodium oxide-nanoporous nickel composite electrode:

[0053] (1) Preparation of porous nickel: adopt template method to prepare nanoporous nickel, concrete method is: earlier the polystyrene microsphere that diameter is 200-300nm is dispersed in deionized water with the mass concentration of 1-5wt%, forms stable suspension. Using polyimide copper-clad laminate as the working electrode and platinum mesh as the counter electrode, electrophoretic deposition was carried out in the polystyrene microsphere emulsion prepared above. The voltage of electrodeposition was 5V and the time was 5min to obtain the polystyrene microsphere template. . Then configure the nickel electrodeposition solution, specifically 1.0M nickel sulfamate tetrahydrate, 0.02M nickel chloride and 0.3M boric acid. The polystyrene microsphere template is used as the working electrode, the platinum sheet is used as the counter electrode, and the current density is set at 12.0mA / cm 2 , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com