Photosensitizer-loaded painless soluble microneedle, microneedle array and preparation method

A microneedle array and photosensitizer technology, applied in microneedle, phototherapy, laser welding equipment, etc., can solve problems such as unreasonable drug delivery methods, achieve the effects of improving transdermal efficiency, shortening treatment time, and avoiding toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

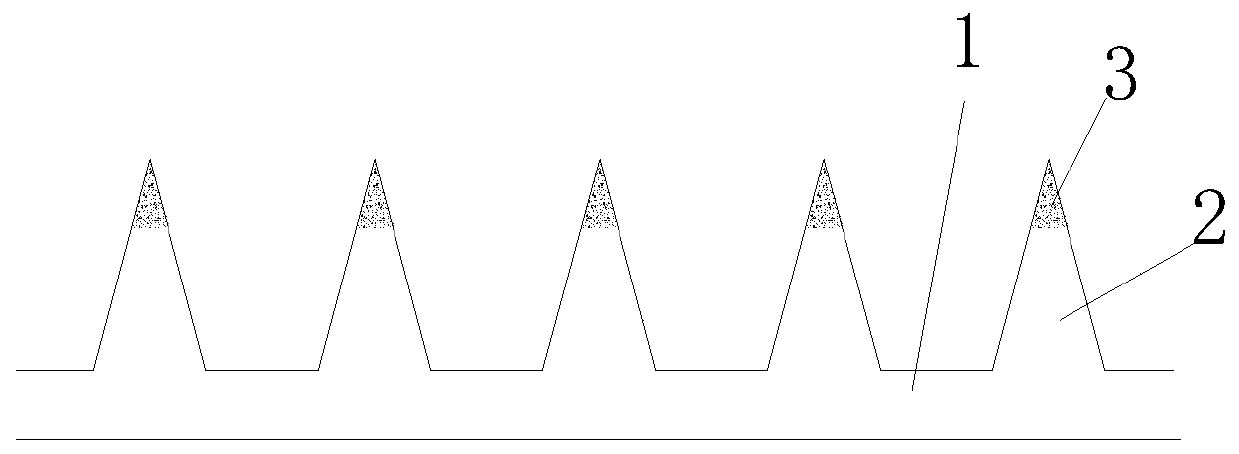

[0040] A preparation method of a painless soluble microneedle array carrying photosensitizer, comprising the following steps:

[0041] 1) Preparation of polydimethylsiloxane (PDMS) mold plate: place polydimethylsiloxane (polydimethylsiloxane (PDMS)) and curing agent in a beaker, stir well, and then set Remove the air bubbles in an ultrasonic cleaning machine, then pour the above mixture into a disposable petri dish and spread it flat; put the petri dish into a constant temperature vacuum drying oven, evacuate to remove all air bubbles in the mixture, and heat it to make the mixture Polysiloxane (PDMS) is solidified; after cooling, the solidified polydimethylsiloxane (PDMS) is peeled from the petri dish to obtain a polydimethylsiloxane (PDMS) mold plate;

[0042] 2) Laser etching polydimethylsiloxane (PDMS) microneedle female mold: Use an integrated fiber carbon dioxide laser marking machine to set parameters to etch the polydimethylsiloxane (PDMS) mold plate to remove excess materi...

Embodiment 1

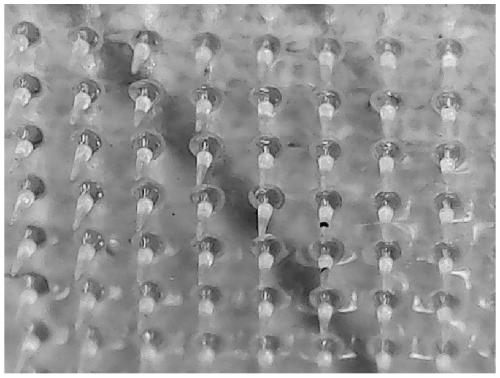

[0059] Example 1: Preparation of soluble hyaluronic acid microneedles loaded with 5-ALA and lidocaine

[0060] 1. Preparation of polydimethylsiloxane (PDMS) mold plate: Place polydimethylsiloxane (polydimethylsiloxane (PDMS)) and curing agent in a beaker at a mass ratio of 10:1 , Stir for about 5 minutes, then place in an ultrasonic cleaning machine for about 10 minutes to remove air bubbles, and then pour the above mixture into a disposable petri dish to make the thickness about 3-4 mm. Put the petri dish into a constant-temperature vacuum drying box, and evacuate to a vacuum of -0.08 MPa to remove all bubbles in the mixture. Heat at 80°C for 2h to solidify the polydimethylsiloxane (PDMS); after cooling, peel off the cured polydimethylsiloxane (PDMS) to obtain a polydimethylsiloxane (PDMS) mold plate .

[0061] 2. Laser etching polydimethylsiloxane (PDMS) microneedle female mold: use an integrated fiber CO2 laser marking machine to set the parameters to etch the polydimethylsilo...

Embodiment 2

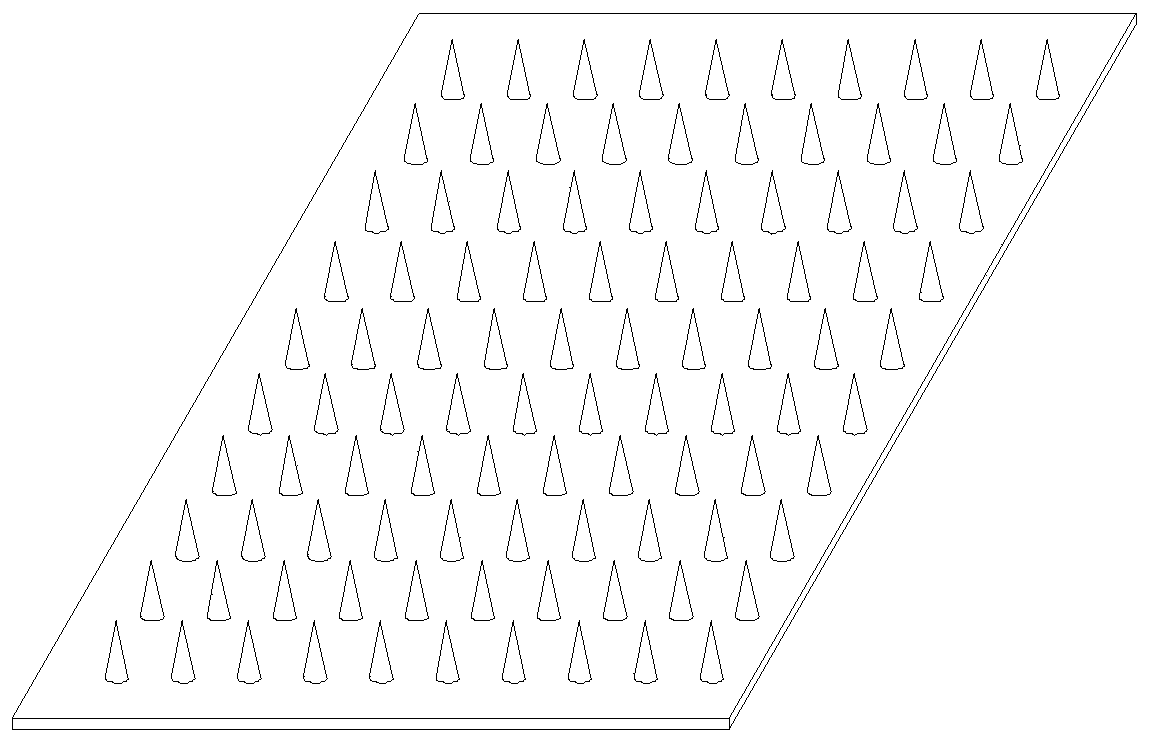

[0064] Example 2-6: Painless soluble photodynamic therapy microneedles with different parameters

[0065] In addition, according to the method of Example 1, by adjusting the structure of the polydimethylsiloxane (PDMS) microneedle female mold and the concentration of the photosensitizer solution, microneedles with various parameters as shown in Table 1 were obtained.

[0066] The painless soluble photodynamic therapy microneedles with different lengths, base diameters, distance between adjacent needle tips, photosensitizer types, and photosensitizer content prepared by the method of Example 1 of the present invention, the results are as follows:

[0067]

[0068] The compression time during treatment is 1s to 10min, and the time interval from the start of compression to the irradiation of excitation light is 10min to 24h.

[0069] Application of soluble microneedle with photosensitizer in tumor detection

[0070] 1. Prepare 5-ALA-loaded soluble hyaluronic acid microneedles (including 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com