Method for preparing mycelium/molybdenum oxide adsorption-catalytic material by utilizing biological enrichment

A catalytic material and bioconcentration technology, applied in the field of adsorption-catalytic material preparation, can solve the problems of wide band gap, limited catalytic reduction ability, uranium occupancy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

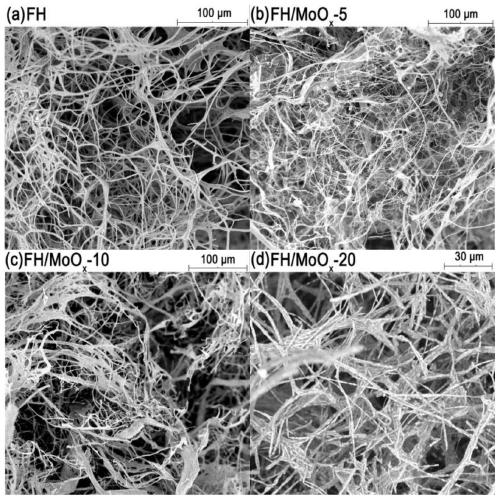

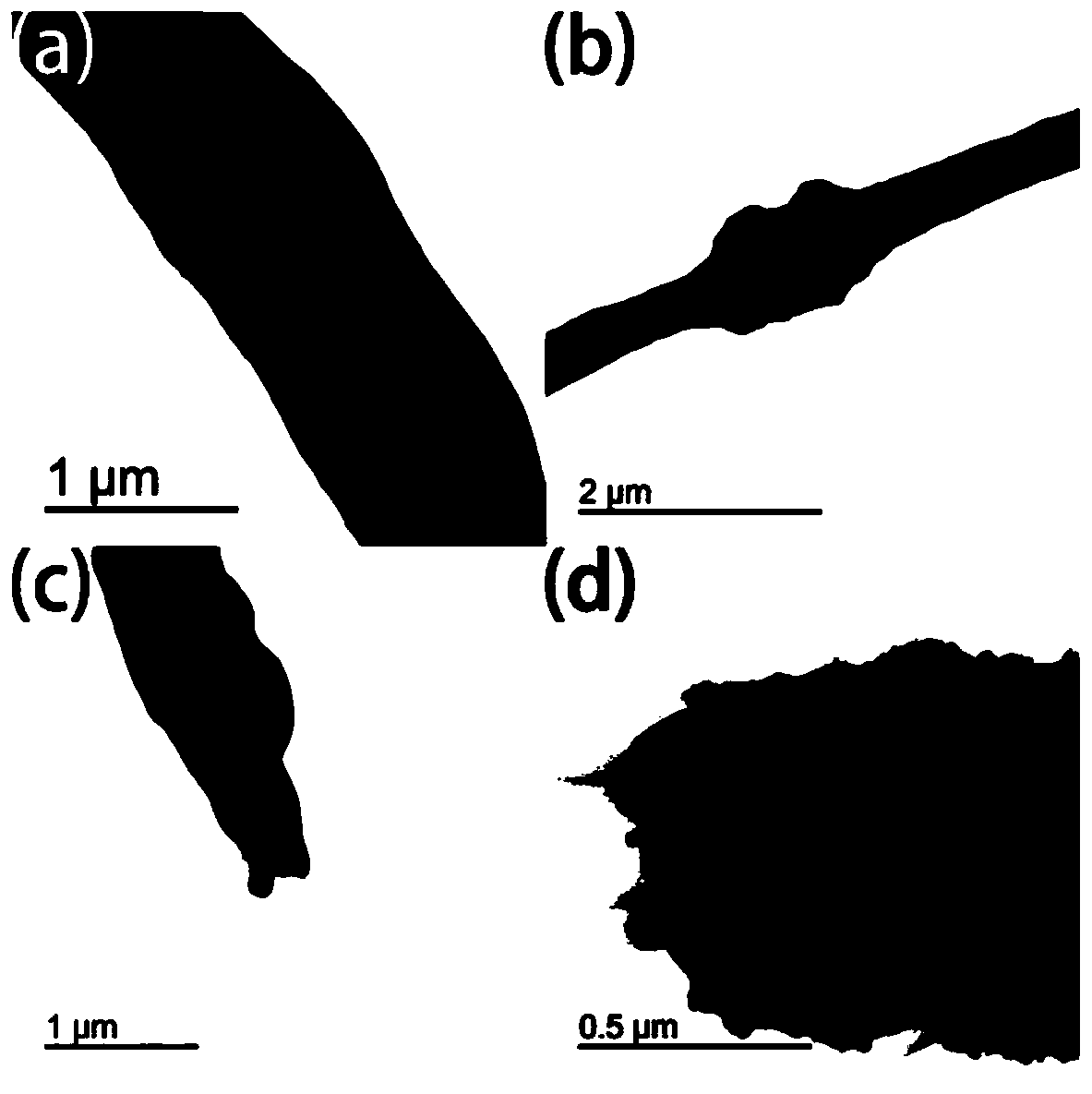

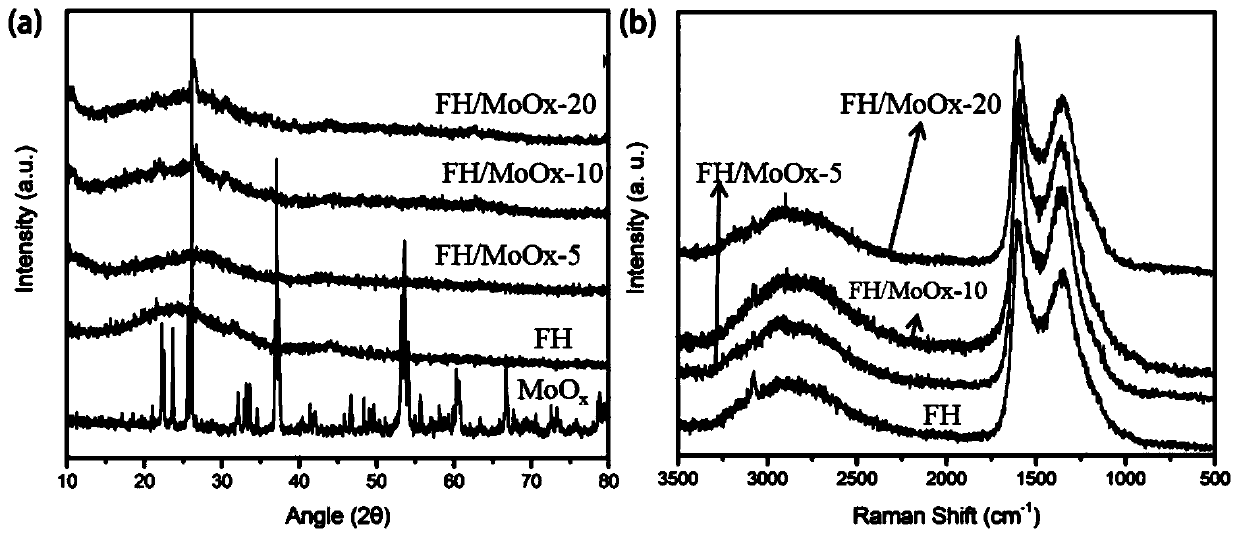

[0037] A method for preparing hyphae / molybdenum oxide adsorption-catalytic material by bio-enrichment, comprising the following steps:

[0038] Step 1. Take 100g of glucose, 12.5g of yeast extract powder, 12.5g of peptone, and 5L of deionized water, mix them, and maintain them for 20 minutes under the conditions of steam pressure of 103.4kPa and temperature of 120°C for sterilization to obtain sterilized liquid medium;

[0039] Step 2: Add 120mL of liquid culture medium to the culture container, then add 0.1g of the fungal strain Xylocarpus, shake and cultivate at a temperature of 28°C and a speed of 180rpm. When the diameter of the fungal mycelium in the liquid culture medium grows to 1cm diameter, add 20 mL of 50 g / L ammonium molybdate solution in an amount of 5 mL per day, and continue to cultivate for 1 day. After the cultivation, the solid matter is taken out and washed with deionized water to neutrality, and then freeze-dried; the freeze-dried It includes two stages, re...

Embodiment 2

[0042] A method for preparing hyphae / molybdenum oxide adsorption-catalytic material by bio-enrichment, comprising the following steps:

[0043] Step 1. Take 100g of glucose, 12.5g of yeast extract powder, 12.5g of peptone, and 5L of deionized water, mix them, and maintain them for 20 minutes under the conditions of steam pressure of 103.4kPa and temperature of 120°C for sterilization to obtain sterilized liquid medium;

[0044] Step 2: Add 120mL of liquid culture medium to the culture container, then add 0.1g of the fungal strain Xylocarpus, shake and cultivate at a temperature of 28°C and a speed of 180rpm. When the diameter of the fungal mycelium in the liquid culture medium grows to 1cm diameter, add 20 mL of 50 g / L ammonium molybdate solution in an amount of 5 mL per day, and continue to cultivate for 1 day. After the cultivation, the solid matter is taken out and washed with deionized water to neutrality, and then freeze-dried; the freeze-dried It includes two stages, re...

Embodiment 3

[0047] A method for preparing hyphae / molybdenum oxide adsorption-catalytic material by bio-enrichment, comprising the following steps:

[0048] Step 1. Take 100g of glucose, 12.5g of yeast extract powder, 12.5g of peptone, and 5L of deionized water, mix them, and maintain them for 20 minutes under the conditions of steam pressure of 103.4kPa and temperature of 120°C for sterilization to obtain sterilized liquid medium;

[0049] Step 2: Add 120mL of liquid culture medium to the culture container, then add 0.1g of the fungal strain Xylocarpus, shake and cultivate at a temperature of 28°C and a speed of 180rpm. When the diameter of the fungal mycelium in the liquid culture medium grows to 1cm diameter, add 20 mL of 50 g / L ammonium molybdate solution in an amount of 5 mL per day, and continue to cultivate for 1 day. After the cultivation, the solid matter is taken out and washed with deionized water to neutrality, and then freeze-dried; the freeze-dried It includes two stages, re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com