2D/2Dg-C3N4CoAl-LDH hydrogen production heterojunction material as well as preparation method and application of 2D/2Dg-C3N4CoAl-LDH hydrogen production heterojunction material

A 2dg-c3n4coal-ldh, 2dg-c3n4 technology, applied in the field of material preparation and renewable clean energy utilization, can solve the problems of small contact interface area and low reactivity, achieve high purity, good photoelectric performance, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

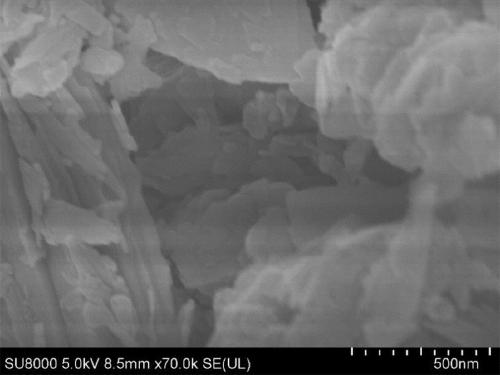

[0022] Get 10 g of melamine in a crucible, put the lid on and place it in a muffle furnace at 550 o Calcined at C for 4 h (heating rate 2.3 o C / min) After naturally cooling to room temperature, the sample was taken out and ground to obtain a yellow carbon nitride precursor, marked as g-C 3 N 4 ; Take 0.5 g of g-C 3 N 4 Sonicate in 50 mL of deionized water for 2 h, and centrifuge the resulting suspension at 3000 rpm to remove g-C at the bottom. 3 N 4 Precipitate, giving g-C 3 N 4 nanosheet suspension.

Embodiment 2

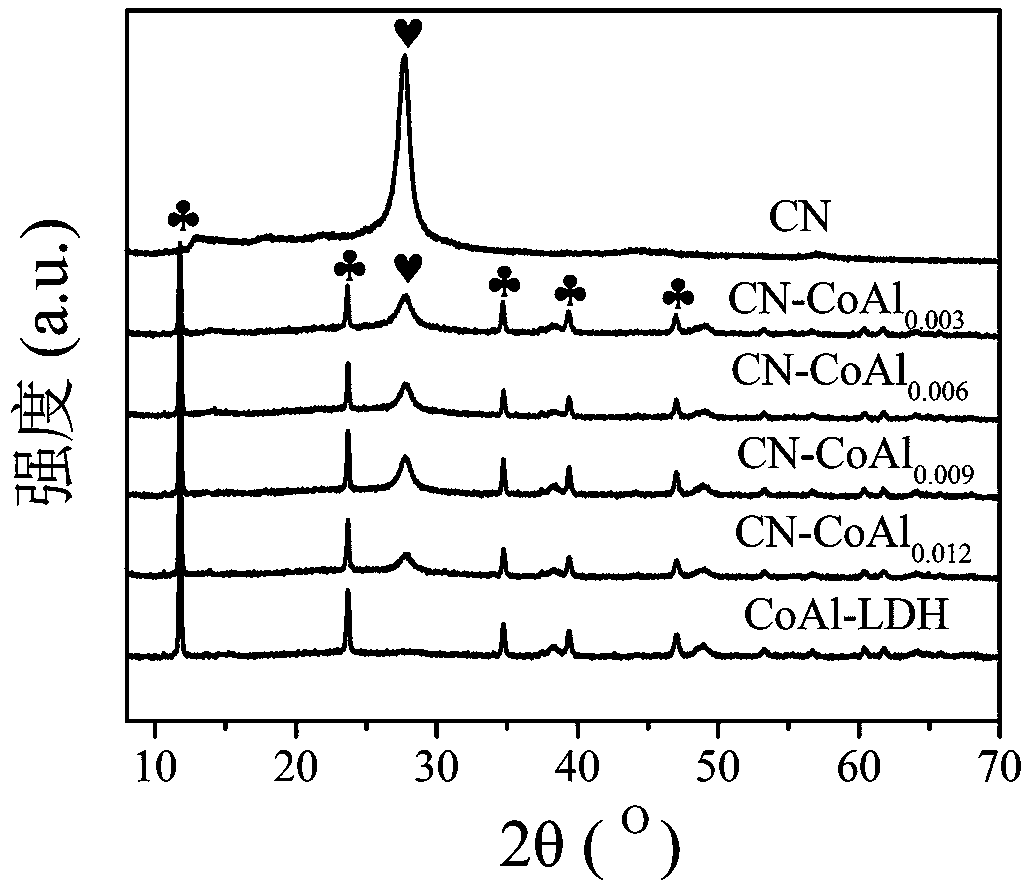

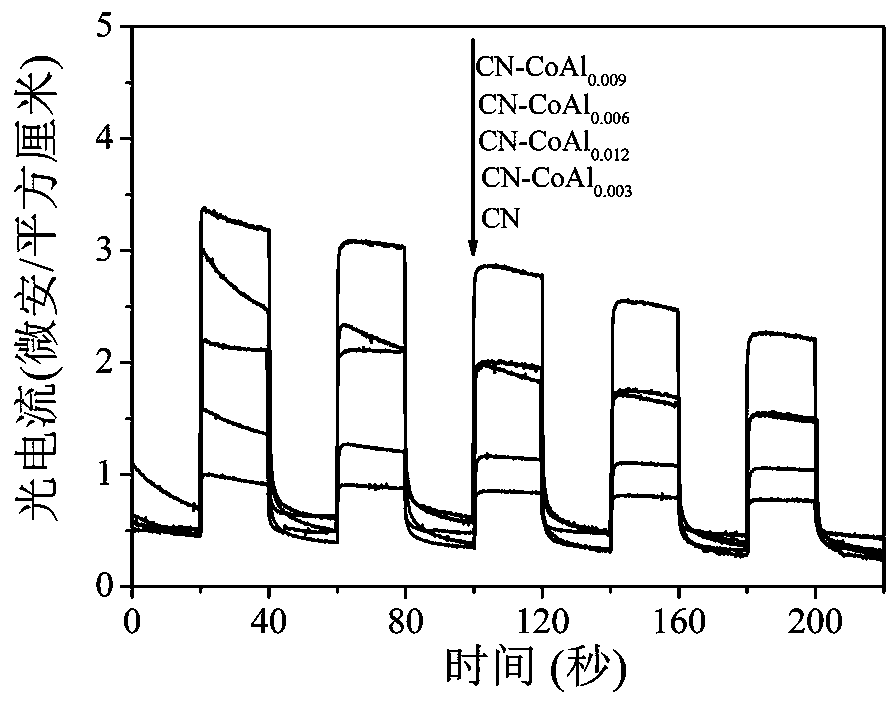

[0024] Get 10 g of melamine in a crucible, put the lid on and place it in a muffle furnace at 550 o Calcined at C for 4 h (heating rate 2.3 o C / min) After naturally cooling to room temperature, the sample was taken out and ground to obtain a yellow carbon nitride precursor, marked as g-C 3 N 4 ; Take 0.5 g of g-C 3 N 4 Sonicate in 50 mL of deionized water for 2 h, and centrifuge the resulting suspension at 3000 rpm to remove g-C at the bottom. 3 N 4 Precipitate, giving g-C 3 N 4nanosheet suspension. Add 0.003 mol Co(NO 3 ) 2 and 0.001 mol Al(NO 3 ) 2 , 0.5 g urea and stirred for 0.5 h at 120 o C under hydrothermal reaction for 12 h, cooled to room temperature and centrifuged, the precipitate was washed with distilled water and ethanol, 60 o The powder solid obtained by C vacuum drying is marked as CN-CoAl 0.003 .

Embodiment 3

[0026] Get 10 g of melamine in a crucible, put the lid on and place it in a muffle furnace at 550 o Calcined at C for 4 h (heating rate 2.3 o C / min) After naturally cooling to room temperature, the sample was taken out and ground to obtain a yellow carbon nitride precursor, marked as g-C 3 N 4 ; Take 0.5 g of g-C 3 N 4 Sonicate in 50 mL of deionized water for 2 h, and centrifuge the resulting suspension at 3000 rpm to remove g-C at the bottom. 3 N 4 Precipitate, giving g-C 3 N 4 nanosheet suspension. Add 0.006 mol Co(NO 3 ) 2 and 0.002 mol Al(NO 3 ) 2 , 0.5 g urea and stirred for 0.5 h at 120 o C under hydrothermal reaction for 12 h, cooled to room temperature and centrifuged, the precipitate was washed with distilled water and ethanol, 60 o The powder solid obtained by C vacuum drying is marked as CN-CoAl 0.006 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com