High-bonding-strength mildew-proof heat-insulation and -preservation coating and preparation method thereof

A thermal insulation and high bonding technology, which is applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems that affect the wide application in the construction industry and reduce the bonding strength of thermal insulation coatings, etc., and achieve hand feeling Good, improve construction performance, reduce heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

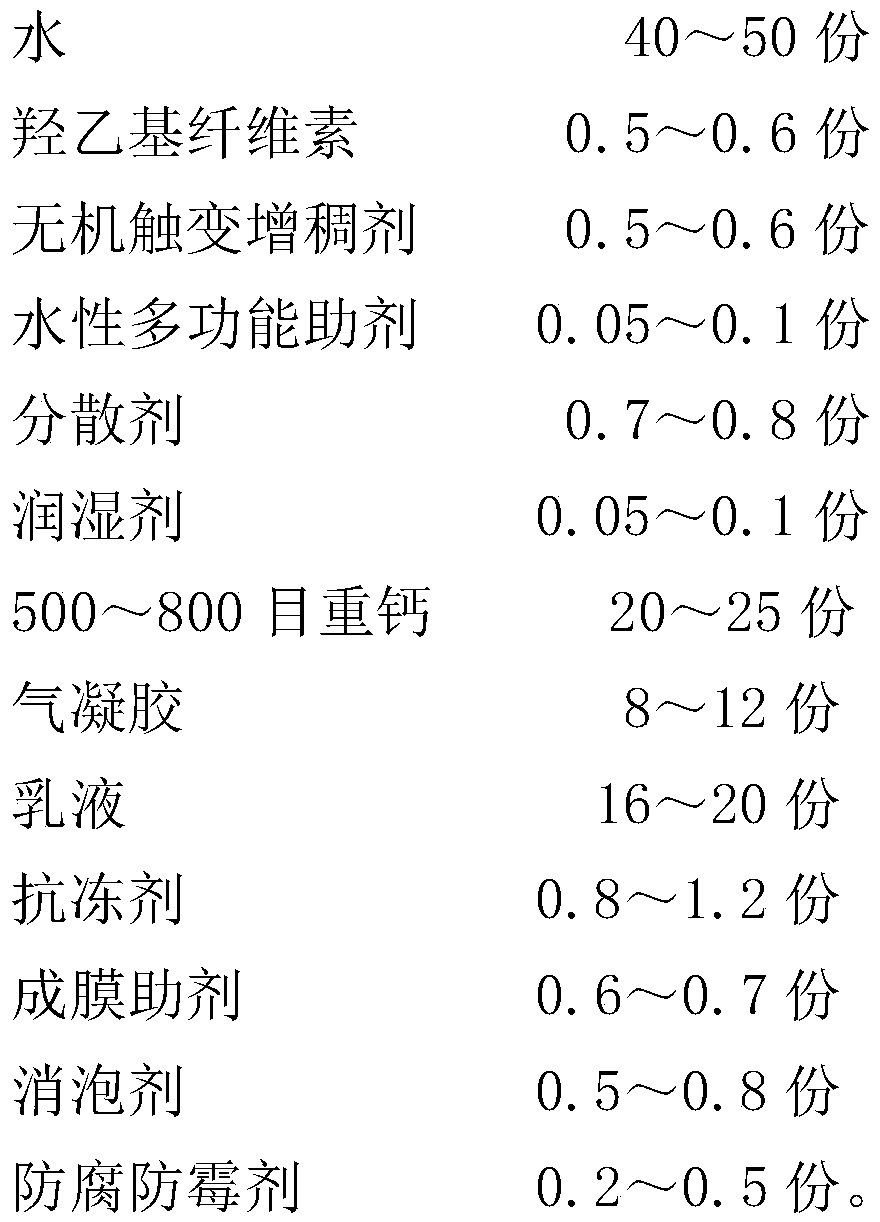

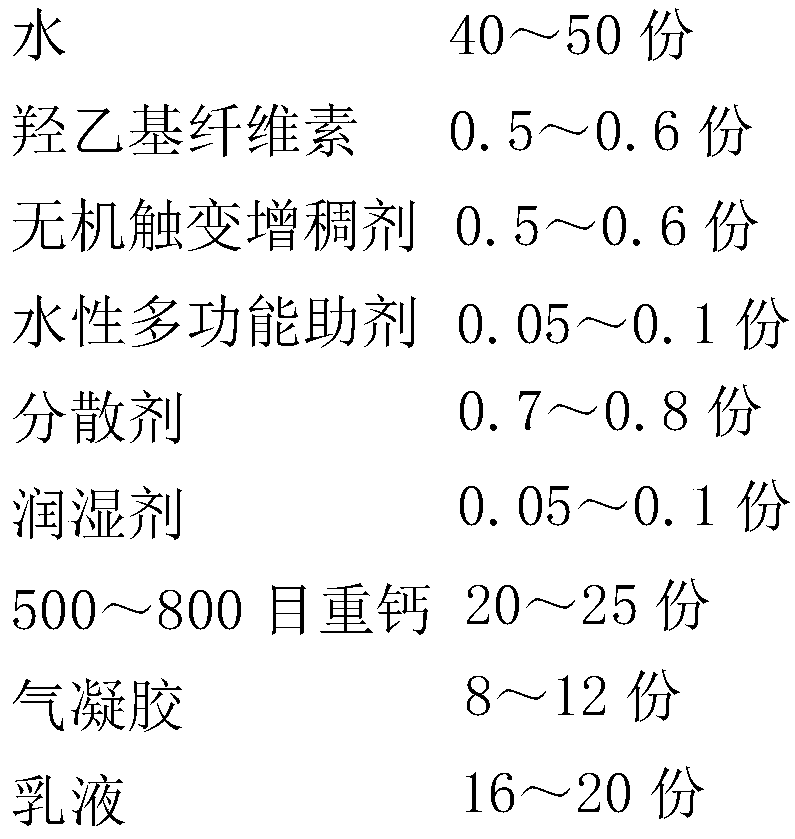

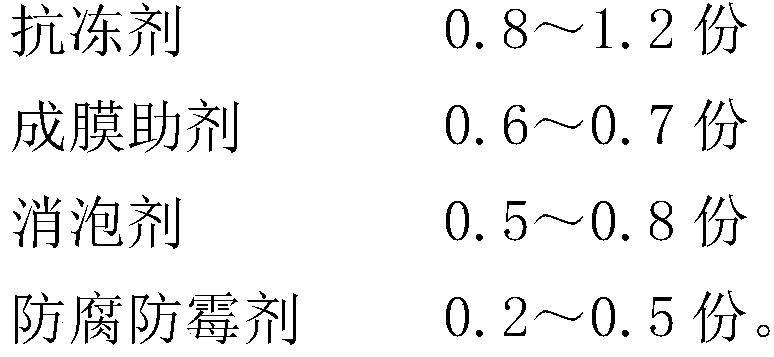

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for a high bond strength mildew-resistant heat-insulating coating, which comprises the following steps in sequence:

[0027] (1) Add 20 parts of water into the dispersion tank, then add 0.7 parts of dispersant, 0.05 parts of wetting agent, 0.3 parts of defoamer, 0.5 parts of hydroxyethyl cellulose, and 0.5 parts of thixotropic After the thickener and 0.05 parts of multifunctional additives, stir for 2 minutes;

[0028] (2) Then increase the rotating speed to 850r / min, after 22 parts of 500 mesh heavy calcium and 9 parts of airgel in sequence, increase the rotating speed again to 1800r / min and disperse for 16min, then check whether the fineness is ≤60μm, if the fineness is ≤ 60 μm, then proceed to step (3);

[0029] (3) Reduce the rotational speed to 1000r / min, add 10 parts of styrene-acrylic and 6 parts of elastic emulsion, 0.6 parts of film-forming aids, 0.7 parts of antifreeze, 0.3 parts of defoamers, 0.3 parts of anti-corrosion and anti-mold age...

Embodiment 2

[0031] A preparation method for a high bond strength mildew-resistant heat-insulating coating, which comprises the following steps in sequence:

[0032] (1) Add 22 parts of water into the dispersion tank, then add 0.8 parts of dispersant, 0.06 parts of wetting agent, 0.4 parts of defoamer, 0.5 parts of hydroxyethyl cellulose, and 0.5 parts of thixotropic After the thickener and 0.06 parts of multifunctional additives, stir for 3 minutes;

[0033] (2) Then increase the speed to 900r / min, after 23 parts of 500 mesh heavy calcium and 10 parts of airgel in sequence, increase the speed again to 1900r / min and disperse for 18min, then check whether the fineness is ≤60μm, if the fineness is ≤ 60 μm, then proceed to step (3);

[0034] (3) Reduce the rotational speed to 1100r / min, add 9 parts of styrene-acrylic and 8 parts of elastic emulsion, 0.6 parts of film-forming aids, 0.7 parts of antifreeze, 0.3 parts of defoamers, 0.4 parts of anti-corrosion and anti-mold agents and 23.68 part...

Embodiment 3

[0036] A preparation method for a high bond strength mildew-resistant heat-insulating coating, which comprises the following steps in sequence:

[0037] (1) Add 22 parts of water into the dispersion tank, then add 0.8 parts of dispersant, 0.07 parts of wetting agent, 0.5 parts of defoamer, 0.5 parts of hydroxyethyl cellulose, and 0.5 parts of thixotropic After the thickener and 0.07 parts of multifunctional additives, stir for 3 minutes;

[0038] (2) Then increase the speed to 950r / min, after 22 parts of 500 mesh heavy calcium and 11 parts of airgel in sequence, increase the speed again to 1900r / min and disperse for 18min, then check whether the fineness is ≤60μm, if the fineness is ≤ 60 μm, then proceed to step (3);

[0039] (3) Reduce the speed to 1100r / min, add 10 parts of styrene-acrylic and 7 parts of elastic emulsion, 0.7 parts of film-forming aid, 0.8 parts of antifreeze, 0.3 parts of defoamer, 0.4 parts of anti-corrosion and anti-mold agent and 23.36 parts After wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com