Coking inhibitor special for hazardous waste incinerator and preparation method and application thereof

A technology for coking inhibitor and hazardous waste, applied in the chemical field, can solve the problems of shortening the service life of the incinerator, increasing the loss of smoke exhaust, reducing the incineration efficiency, etc., so as to reduce the cost of manual removal, prevent melting coking, and reduce the probability of coking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

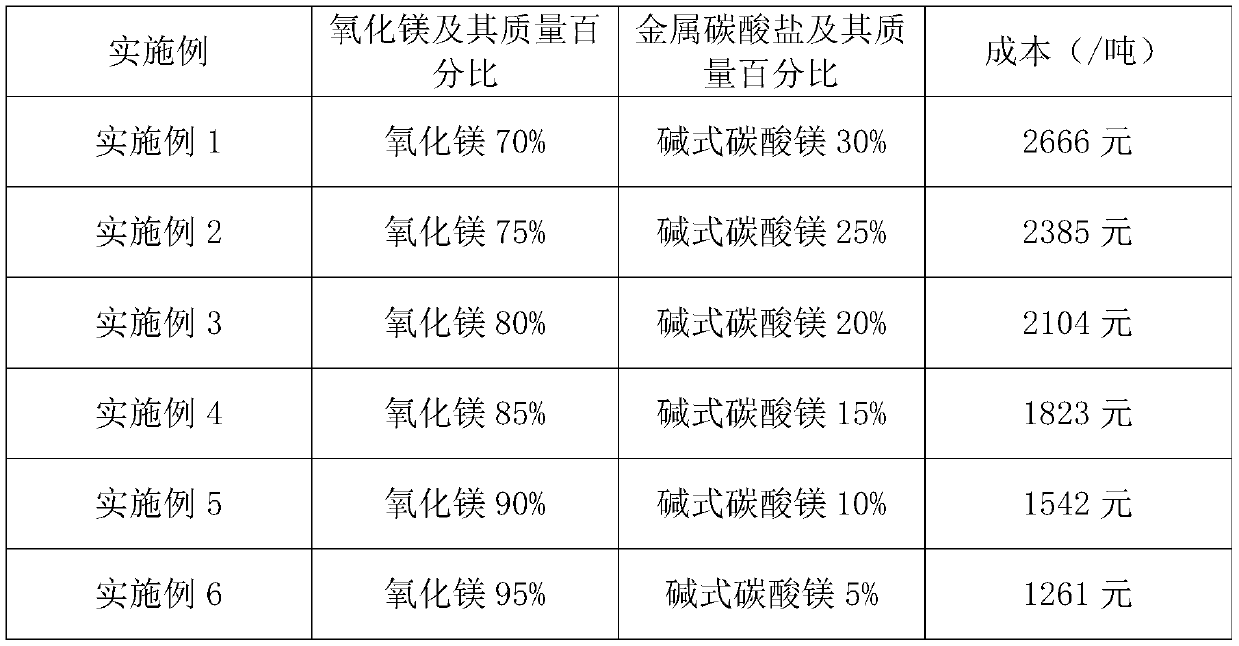

[0023] Add magnesium oxide and basic magnesium carbonate into the mixing equipment according to the ratio described in Table 1 and mix evenly to obtain a special coking inhibitor for hazardous waste incinerators.

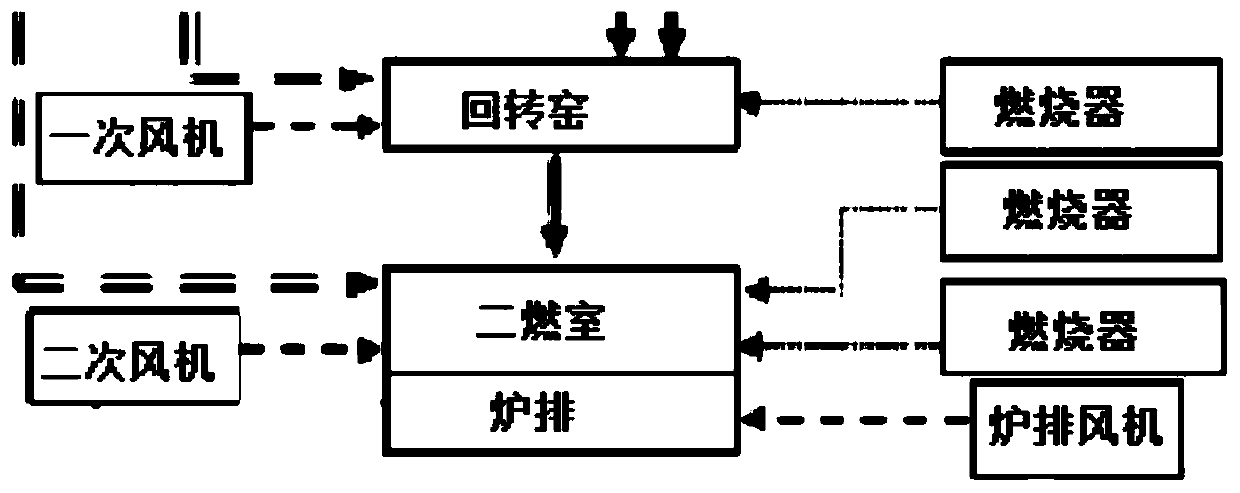

[0024] After the incinerator is started, the waste is pushed into the rotary kiln. In the rotary kiln, the waste goes through the drying section, the volatile matter precipitation section, and the incineration section in sequence. The material is incinerated at high temperature through the above three sections and the burnout section of the second combustion chamber. Pneumatically convey the above-mentioned special coking inhibitor for hazardous waste incinerators to the tail of the rotary kiln, the grate, the constriction of the second combustion chamber and the horizontal flue. Blow onto grate to distribute evenly. After the incineration is completed and the furnace is shut down, the transportation is terminated. The daily delivery volume of the above-mentioned sp...

Embodiment 7-12

[0029] With the difference of embodiment 1-6, only, basic magnesium carbonate is replaced by sodium carbonate.

Embodiment 13-18

[0031] With the difference of embodiment 1-6, only lie in, basic magnesium carbonate is replaced by sodium bicarbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com