Preparation method of cathode material of lithium ion battery and related product thereof

A technology for lithium ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve the problems of inability to observe the growth process, difficult to control the reaction process, incomplete morphology and structure, etc., to improve the cycle. performance, avoid the introduction of impurities, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

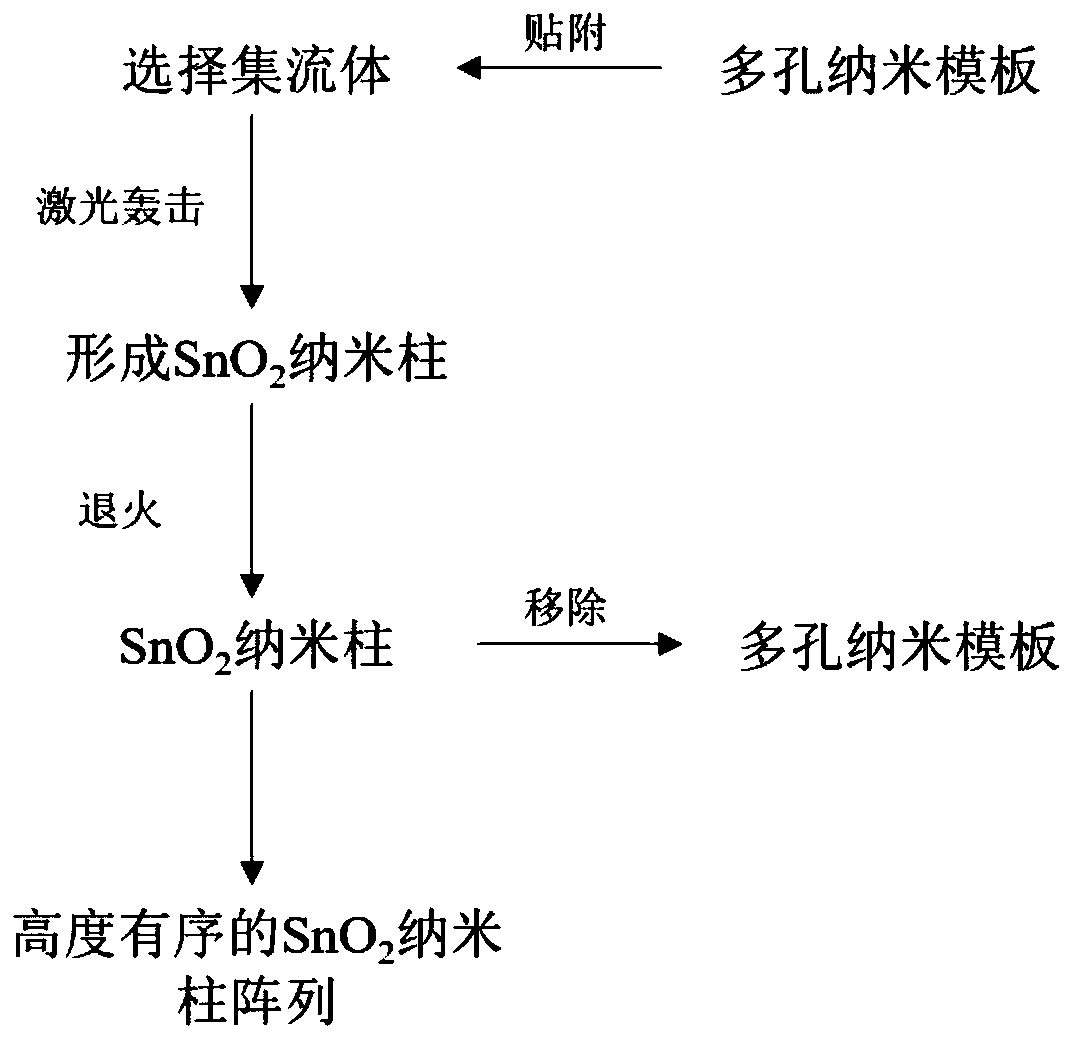

[0053] The technical scheme of the present invention provides a kind of preparation method of lithium-ion battery negative electrode material, with reference to figure 1 shown, including the following steps:

[0054] (1) Select a metal foil as the current collector, and pretreat it, and clean the surface;

[0055] (2) attaching a porous nano-template on the surface of the metal foil through the above-mentioned pretreatment;

[0056] (3) Using a pulsed laser deposition system to deposit SnO 2 ;

[0057] (4) annealing is carried out to the sample that above-mentioned step (3) obtains;

[0058] (5) remove the porous nano-template described in step (2), obtain SnO on the metal foil described in step (1) 2 array of nanopillars.

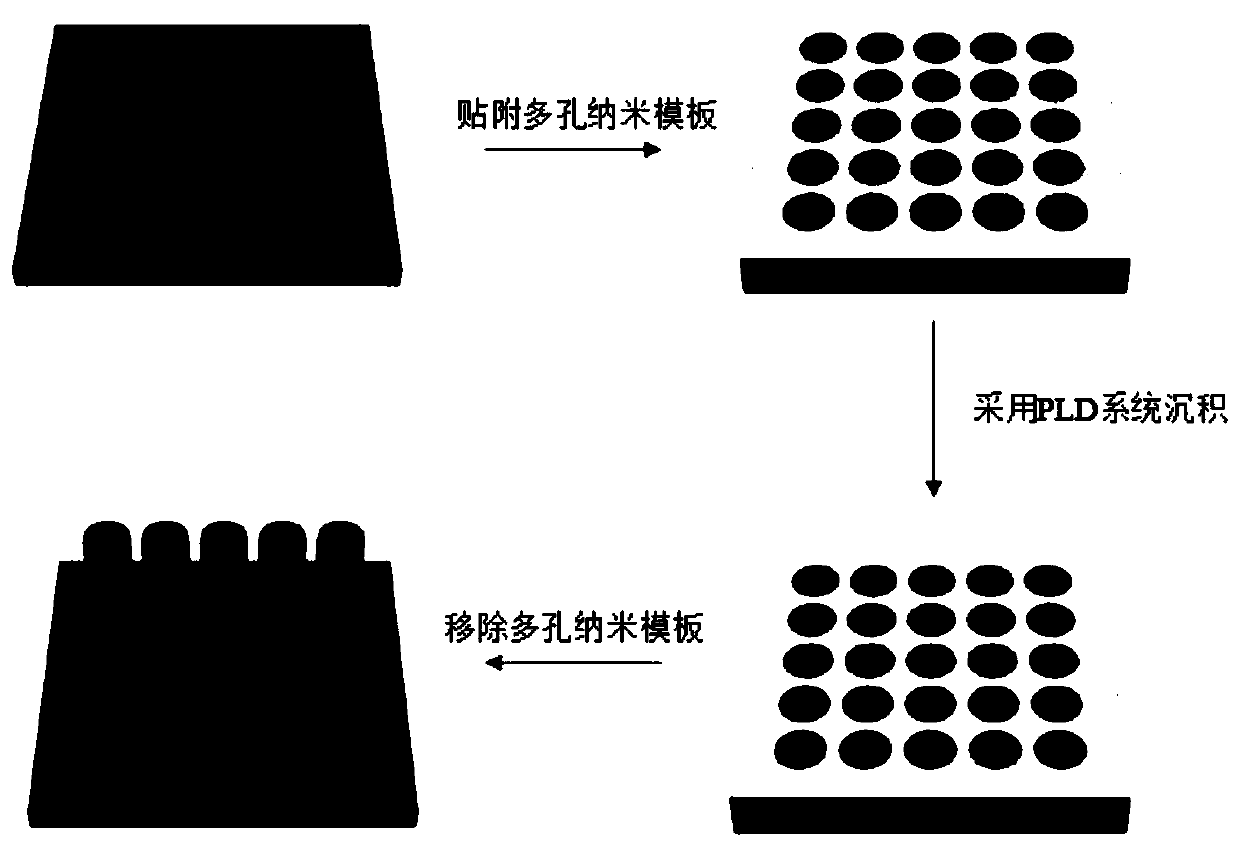

[0059] like figure 2 As shown, it is a schematic diagram of the preparation method of lithium-ion battery negative electrode materials. This method uses pulsed laser deposition (PLD) to prepare lithium-ion battery negative electrode materials, which...

Embodiment 1

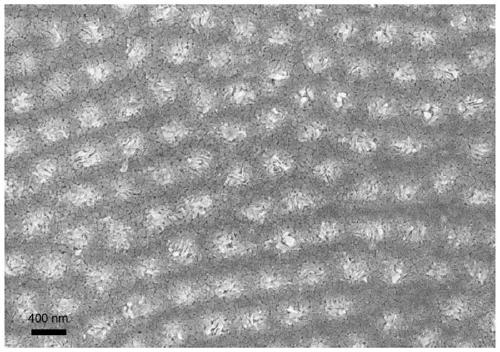

[0063] A preparation method for lithium-ion battery anode materials, using pulsed laser deposition to prepare highly ordered SnO on single-sided smooth Cu foil 2 The nanocolumn array specifically comprises the following steps:

[0064] (1) Select a smooth Cu foil on one side and pretreat it, including the following steps:

[0065] a. Put the selected Cu foil into the acetone (CH 3 COCH 3 ) in a beaker, then put it into an ultrasonic cleaner filled with deionized water, and ultrasonically clean it for 5 minutes at room temperature;

[0066] b. Then immerse the Cu foil in absolute ethanol, and ultrasonically clean it for 5 minutes;

[0067] c. Finally, clean the smooth surface of the Cu foil with a plasma cleaner for 300 s.

[0068] (2) The ultrathin AAO template was soaked in acetone to remove the PMMA support layer, and then transferred in acetone to the smooth surface of the Cu foil cleaned in step (1).

[0069] (3) Preparation of SnO on single-sided smooth Cu foil by pu...

Embodiment 2

[0076] Fabrication of highly ordered SnO on single-sided smooth Cu foils by pulsed laser deposition 2 The nanocolumn array specifically comprises the following steps:

[0077] (1) Select a smooth Cu foil on one side and pretreat it, including the following steps:

[0078] a. Put the cut Cu foil into the acetone (CH 3 COCH 3 ) in a beaker, then put it into an ultrasonic cleaner filled with deionized water, and ultrasonically clean it for 5 minutes at room temperature;

[0079] b. Then immerse the Cu foil in absolute ethanol and ultrasonically clean it for 8 minutes;

[0080] c. Finally, clean the smooth surface of the Cu foil with a plasma cleaner for 250 s.

[0081] (2) The ultrathin AAO template was soaked in acetone to remove the PMMA support layer, and then transferred in acetone to the smooth surface of the Cu foil cleaned in step (1).

[0082] (3) Preparation of SnO on single-sided smooth Cu foil by pulsed laser deposition 2 nanopillars. Deposit at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com