Method for preparing mask base cloth

A base fabric and mask technology, applied in skin care preparations, non-woven fabrics, pharmaceutical formulations, etc., can solve the decline in mechanical properties such as strength and elongation at break, increase the bending stiffness of base fabrics, and improve facial skin fit. Poor and other problems, to avoid uneven entanglement points, improve entanglement effect, and enhance the effect of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]A kind of preparation method of the facial mask base cloth of superhigh biocompatibility, carry out as follows:

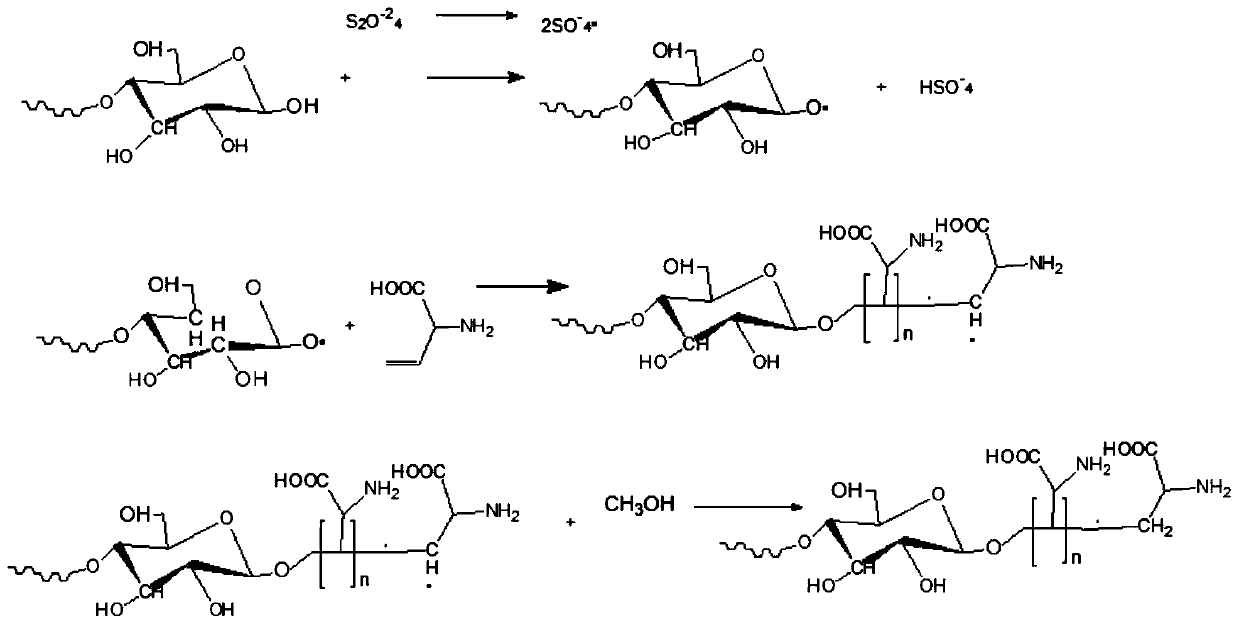

[0041] 1. Modified fiber preparation

[0042] (1) Add 0.2 parts by weight of emulsifier and 0.4 part of pH regulator in 100 parts by weight of water medium in the reactor, the emulsifier is sodium stearate, and the pH regulator is borax;

[0043] (2) Add 25 parts by weight of viscose fiber in the reactor, the steam space in the reactor is replaced with nitrogen to go out the air earlier, and the oxygen content in the steam space is 15ppm;

[0044] (3) Reactor is heated up to 90 DEG C, and pH is controlled at 4, and 0.05 parts by weight of initiator is added to start the polymerization reaction, and the initiator is sodium persulfate;

[0045] (4) Add 0.05 parts of chain transfer agent after the reaction starts, and continuously add vinyl amino acid at a rate of 3 parts by weight / hour, and the chain transfer agent includes methanol;

[0046] (5) When the amo...

Embodiment 2

[0057] A kind of preparation method of the facial mask base cloth of superhigh biocompatibility, carry out as follows:

[0058] 1. Modified fiber preparation

[0059] (1) in the reactor, add 0.01 weight part emulsifier and 0.015 part of pH regulator in every 100 parts by weight of water medium, emulsifier is sodium lauryl sulfate, and pH regulator is dipotassium hydrogen phosphate;

[0060] (2) Add 10 parts by weight of viscose fiber in the reactor, the steam space in the reactor is replaced with nitrogen to go out the air earlier, and the oxygen content in the steam space is 10ppm;

[0061] (3) The temperature of the reactor is raised to 70° C., the pH is controlled at 5, and 0.01 parts by weight of an initiator is added to start the polymerization reaction. The initiator is azobisisobutylamidine dihydrochloride;

[0062] (4) Add 0.01 part of chain transfer agent after the reaction starts, and continuously add 2-amino-3-methylenebutyric acid at a speed of 1 part by weight / ho...

Embodiment 3

[0069] A kind of preparation method of the facial mask base cloth of superhigh biocompatibility, carry out as follows:

[0070] 1. Modified fiber preparation

[0071] (1) Add 0.3 parts by weight of emulsifier and 0.5 part of pH regulator in every 100 parts by weight of water medium in the reactor, the emulsifier is sodium lauryl sulfate, and the pH regulator is sodium bicarbonate;

[0072] (2) Add 30 parts by weight of viscose fiber in the reactor, the steam space in the reactor is replaced with nitrogen to go out the air earlier, and the oxygen content in the steam space is 5ppm;

[0073] (3) The temperature of the reactor is raised to 120° C., the pH is controlled at 3, and 0.1 parts by weight of an initiator is added to start the polymerization reaction. The initiator includes peroxysuccinic acid;

[0074] (4) Add 1 part of chain transfer agent after the reaction starts, continuously add 2-amino-3-methylenevaleric acid, the addition speed is 5 parts by weight / hour, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com