Lignin cationic surfactant, preparation method thereof, long-acting antibacterial agent and preparation method of long-acting antibacterial agent

A surfactant and lignin technology, applied in the field of antibacterial agents, can solve the problems of bacterial resistance, short protection time, and low sterilization rate, and achieve long protection time, fast sterilization speed, and high sterilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of lignin cationic surfactant, comprises the following steps:

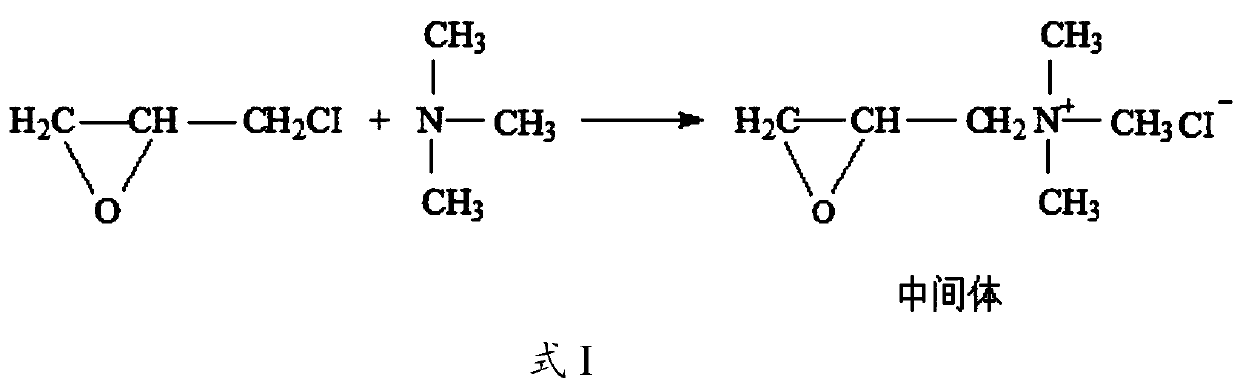

[0027] (1) Carry out nucleophilic substitution reaction with tertiary amine and epichlorohydrin to obtain intermediate product;

[0028] (2) Mixing the intermediate product and lignin for grafting reaction to obtain a lignin cationic surfactant.

[0029] In the invention, the tertiary amine and epichlorohydrin are subjected to nucleophilic substitution reaction to obtain intermediate products. In the present invention, the tertiary amine is preferably one or more of trimethylamine, triethylamine, tripropylamine and tributylamine; the mass ratio of the epichlorohydrin to the tertiary amine is preferably 0.8 to 1: 1, more preferably 0.85-0.9:1.

[0030] In the present invention, the nucleophilic substitution reaction is specifically preferably: acidify the tertiary amine under acidic conditions, then add epichlorohydrin to react for 1-2 hours, preferably r...

Embodiment 1

[0050] Add triethylamine under acidic conditions (provided by hydrochloric acid, pH value is 2-3), turn on the stirring device to react for 10 minutes, then add epichlorohydrin, react for 1 hour, adjust the pH to neutral, continue to react for 3 hours, and obtain the intermediate product, Wherein the mass ratio of epichlorohydrin and triethylamine is 1:1.

[0051] Add lignin to the intermediate product, the mass ratio of lignin to intermediate product is 1.5:1, adjust the pH value to be alkaline, raise the temperature to 60°C to start the reaction, and obtain the lignin cationic surfactant after 5 hours of reaction, the active ingredient content was 65.4%.

Embodiment 2

[0053] Add trimethylamine under acidic conditions (provided by hydrochloric acid, pH value is 2-3), start the stirring device to react for 20min, then add epichlorohydrin, react for 1.5h, adjust the pH to neutral, continue to react for 4h, and obtain the intermediate product, Wherein the mass ratio of epichlorohydrin and triethylamine is 0.8:1.

[0054] Add lignin to the intermediate product, the mass ratio of lignin to intermediate product is 1:1, adjust the pH value to be alkaline, raise the temperature to 45°C to start the reaction, and obtain the lignin cationic surfactant after 3 hours of reaction, the active ingredient content was 66.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com