Alkali fusion tubular reactor for resorcinol and method for continuously producing resorcinol by using sulfur trioxide

A tubular reactor, resorcinol base technology, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical/physical chemical processes using energy, etc., can solve the problem of increasing three wastes Difficult to deal with, difficult to deal with sodium sulfate, large environmental pollution and other problems, to achieve good environmental protection effect, saving reaction steps, high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

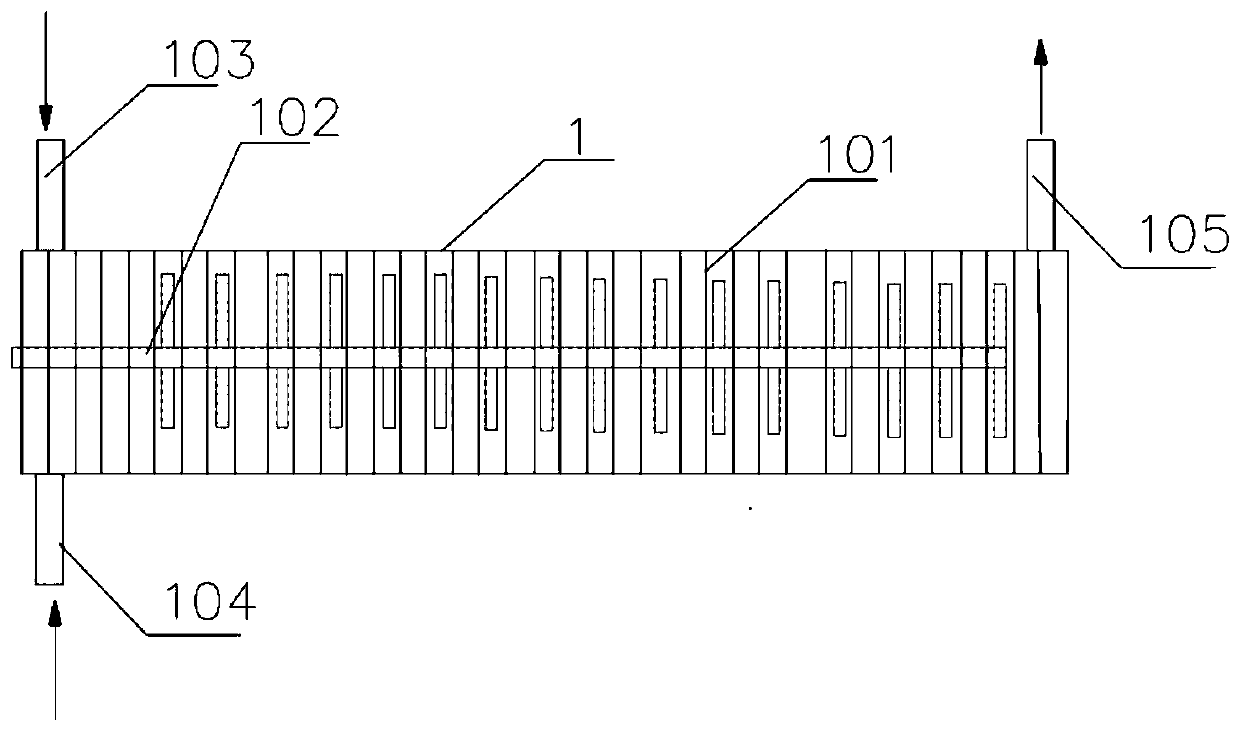

[0033] Such as figure 1 As shown, the resorcinol alkali fusion tubular reactor of the present invention includes a tubular reactor body 1, and the tubular reactor body 1 is made of an electrical conductor, such as the tubular reactor body 1 is made of a nickel alloy material. The tubular reactor body 1 is wound with an electromagnetic coil 101, and the stirring rod of the magnetic stirrer 102 is installed in the tubular reactor body 1 along the axial direction of the tubular reactor body, and the stirring rod is provided with stirring blades. The feed end of the tubular reactor body 1 is provided with a disulfonation product feed pipe 103 and an alkali melt feed pipe 104 , and the discharge end of the tubular reactor body 1 is provided with an alkali melt product discharge pipe 105 . The caustic soda is first heated and melted in the kettle, and then enters the alkali fusion tubular reactor from the alkali melt feed pipe 104.

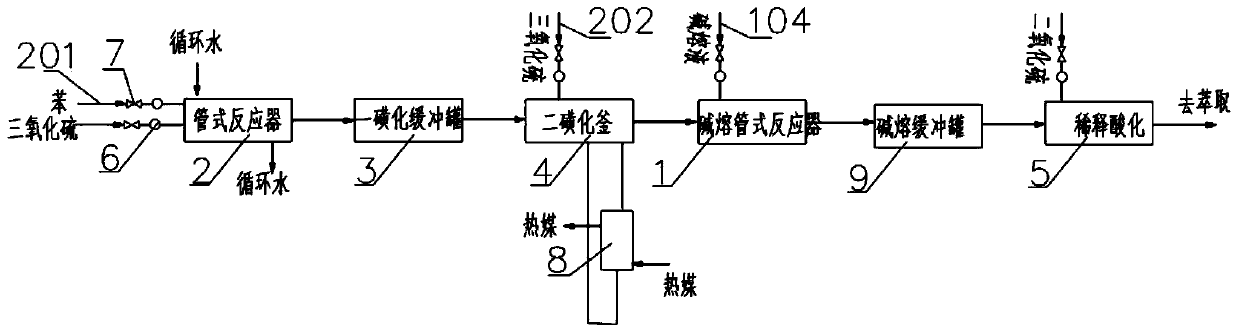

[0034] The resorcinol production system includes...

Embodiment 2

[0041] Method for continuous production of resorcinol using sulfur trioxide

[0042] Turn on the jacket cooling water of a sulfonation tubular reactor, and feed benzene and sulfur trioxide. The molar ratio of sulfur trioxide to benzene is 1.05:1, and the temperature in the pipeline is controlled between 30-40°C. It takes 0.5-1h to pass through the reactor, and then flows into a sulfonation buffer tank.

[0043] Then transfer to the disulfonation reactor, feed sulfur trioxide into the disulfonation reactor at a rate of 0.5-0.8t / h for disulfonation to obtain m-benzenedisulfonic acid, the reaction temperature is 160°C, sulfur trioxide and The molar ratio of benzene is 1.05:1.

[0044] Add sodium hydroxide into the alkali fusion kettle and heat it to 330°C to melt the sodium hydroxide to obtain an alkali solution.

[0045] Then the disulfonated liquid and the alkali melt are controlled according to the feed flow rate of the disulfonated liquid is 1-1.5t / h, the feed flow rate of...

Embodiment 3

[0048] Method for continuous production of resorcinol using sulfur trioxide

[0049] Open the jacket cooling water of the tubular reactor, and feed benzene and sulfur trioxide. The molar ratio to benzene is 1.2:1, and the temperature in the pipeline is controlled between 30-40°C. After passing through the reactor for 0.5-1h, it flows into a sulfonation buffer tank.

[0050] Then transfer to the disulfonation reactor, and then pass sulfur trioxide into the disulfonation reactor at a rate of 0.5-0.8t / h for disulfonation to obtain m-benzenedisulfonic acid. The reaction temperature is 160°C. The molar ratio to benzene is 1.2:1.

[0051] Add sodium hydroxide into the alkali fusion kettle and heat it to 330°C to melt the sodium hydroxide to obtain an alkali solution.

[0052] Then the disulfonated liquid and the alkali melt are controlled according to the feed flow rate of the disulfonated liquid is 1-1.5t / h, the feed flow rate of the alkali melt is 1.2-2t / h, and the molar ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com