Preparation method and application of a high-efficiency hydrogen evolution catalyst ir@nbd-c

A catalyst and hydrogen evolution technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of difficult control of material synthesis conditions and harsh size conditions of metal nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

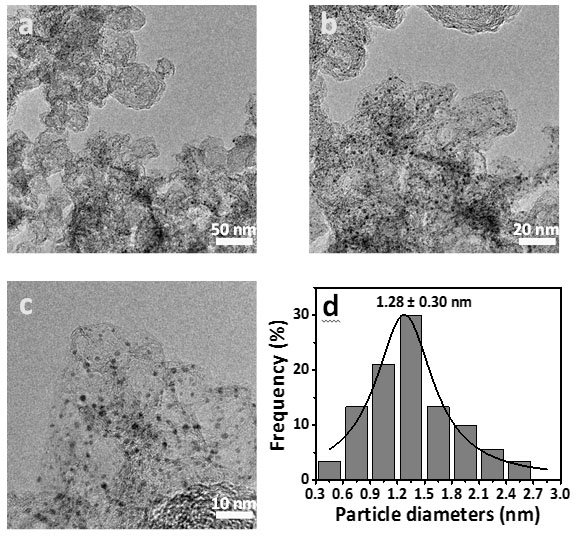

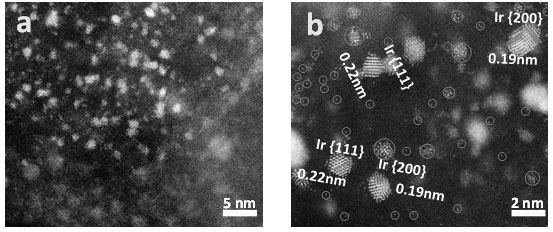

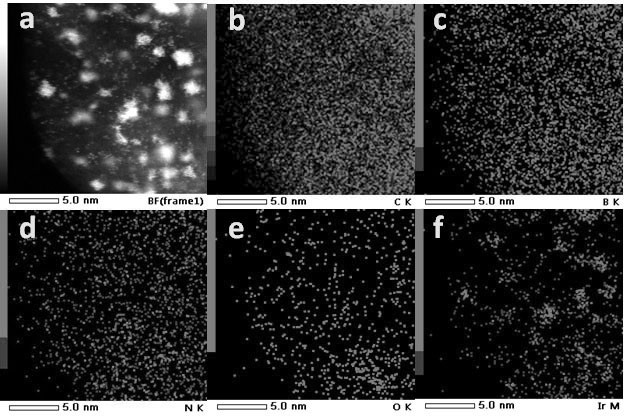

Image

Examples

Embodiment 1

[0046] A method for preparing a high-efficiency hydrogen evolution catalyst Ir@NBD-C, which specifically includes the following steps:

[0047] 1) Add 200 mg of commercial Ketjen Black to 100 ml of toluene for ultrasonic treatment for 30 min to form No. 1 mixed solution;

[0048] 2) Add 2.4g of potassium hydroxide to 50 ml of absolute ethanol, and stir magnetically for 30 minutes to form the No. 2 mixed solution;

[0049] 3) Mix No. 1 mixed solution and No. 2 mixed solution, and then perform magnetic stirring for 120 min to form No. 3 mixed solution;

[0050] 4) Transfer the mixed liquid No. 3 to a three-necked bottle, heat it in an oil bath at 115 °C for 2.5 h, and at the same time continue to mechanically stir until the organic solvent volatilizes, and collect a brown-yellow powder;

[0051] 5) The obtained powder sample was calcined at 700 °C for 0.5 h in an argon atmosphere to obtain a black block;

[0052] 6) with 0.5 M H 2 SO 4 Fully wash the black block to remove al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com