Laser-loaded array catapulting process method

A process method and laser technology, applied in the direction of launch/drag transmission, can solve the problems of high-speed ejection of small-sized components, large ejection material size, low production efficiency, etc., to achieve excellent acceleration effect, increase absorption, The effect of environmental protection automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

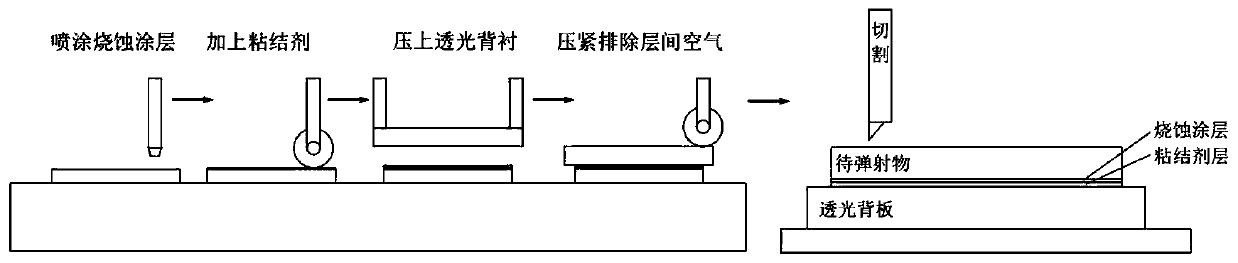

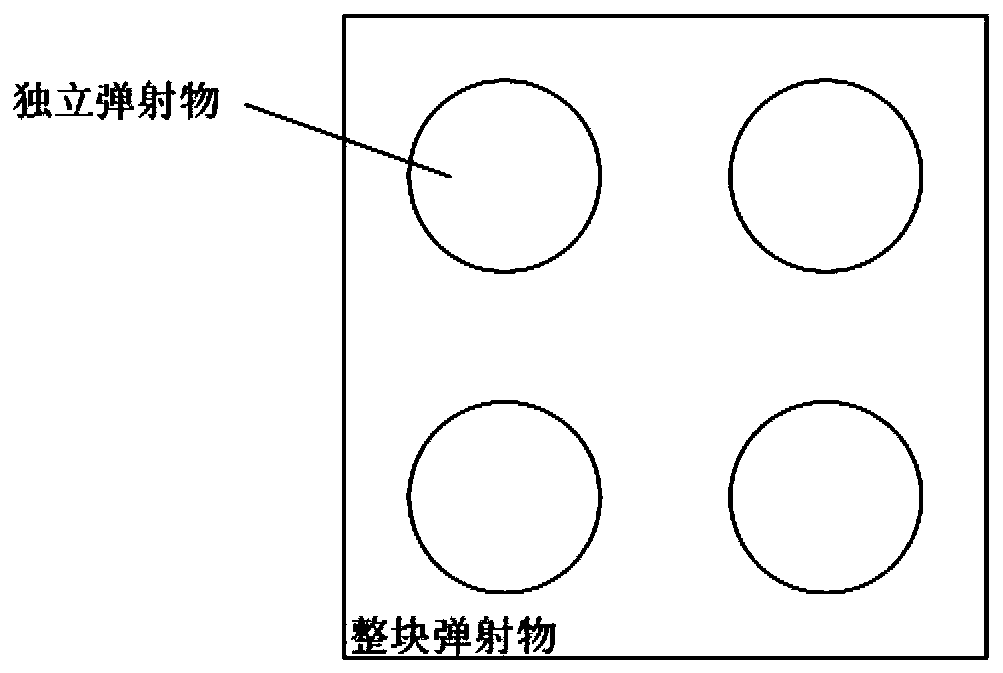

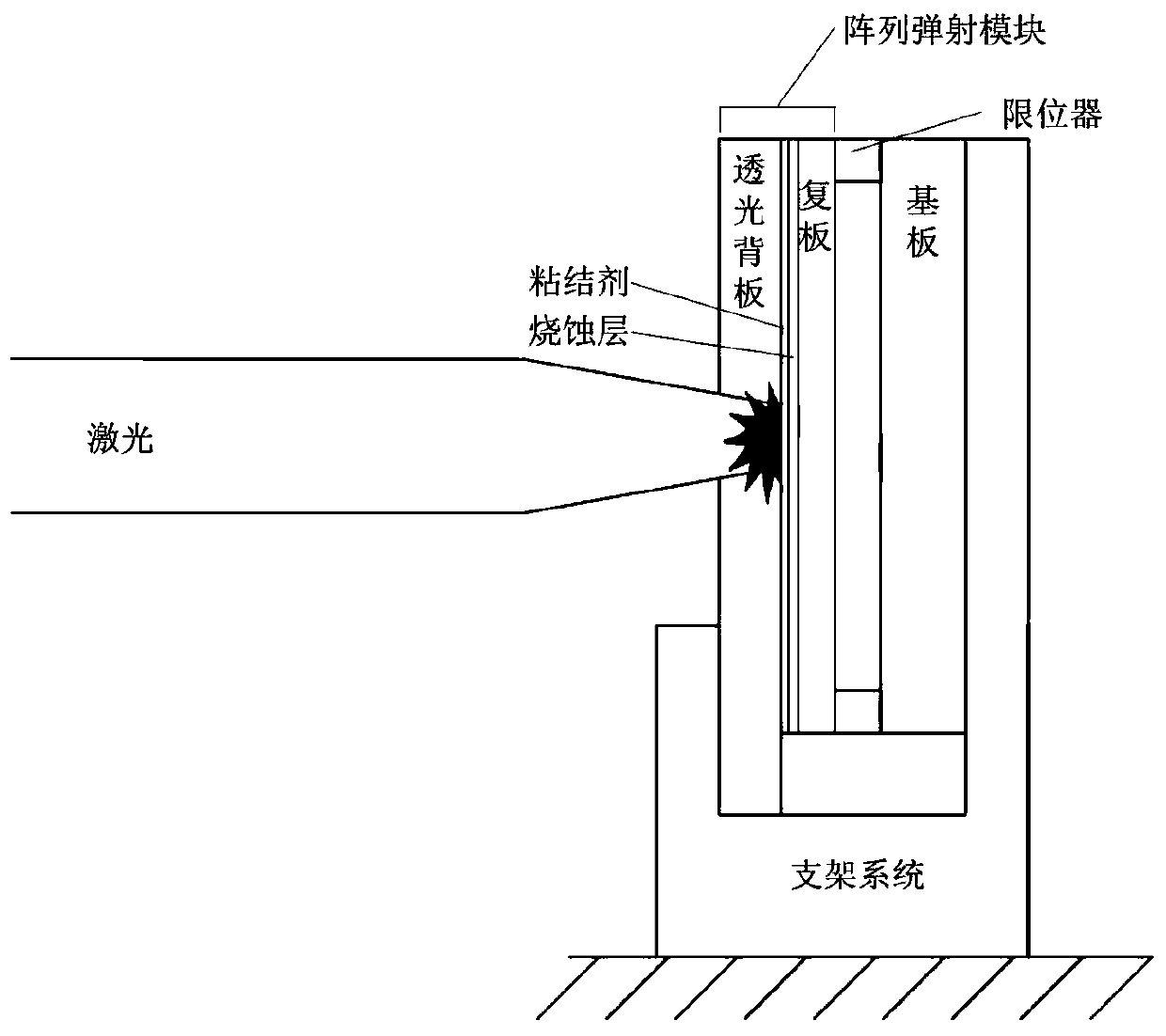

[0030] A laser-loaded array ejection method is characterized in that it includes two parts: a module to be ejected and laser loading: 1. Preparation of a module to be ejected composed of objects to be ejected that are distributed in an array on a light-transmitting backplane; The single pulse laser of the short pulse laser is loaded on the ejection system of the coating. The other parameters are that the single pulse energy of the laser is about 3J. The object to be ejected is a pure aluminum sheet with a thickness of 25 μm. The plate is 0.5mm polycarbonate, the adhesive is double-sided tape, and the light spot is a circle with a diameter of 2mm. PDV test results show that the ejection speed can reach 1000m / s, and this process has excellent ejection performance.

Embodiment 2

[0032] A laser-loaded array ejection method is characterized in that it includes two parts: a module to be ejected and laser loading: 1. Preparation of a module to be ejected composed of objects to be ejected that are distributed in an array on a light-transmitting backplane; The single pulse laser of the short pulse laser is loaded on the ejection system of the coating. The other parameters are that the single pulse energy of the laser is about 3J. The object to be ejected is a pure aluminum sheet with a thickness of 25 μm. The plate is 0.5mm polycarbonate, the adhesive is double-sided tape, and the light spot is a circle with a diameter of 4mm. PDV test results show that the ejection speed can reach 950m / s, and this process has excellent ejection performance.

Embodiment 3

[0034] A laser-loaded array ejection method is characterized in that it includes two parts: a module to be ejected and laser loading: 1. Preparation of a module to be ejected composed of objects to be ejected that are distributed in an array on a light-transmitting backplane; The single pulse laser of the short pulse laser is loaded on the ejection system of the coating. The other parameters are that the single pulse energy of the laser is about 3J. The object to be ejected is a pure aluminum sheet with a thickness of 25 μm. The plate is 0.5mm polycarbonate, the adhesive is double-sided tape, and the light spot is a circle with a diameter of 6mm. PDV test results show that the ejection speed can reach 500m / s, and this process has excellent ejection performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com