Low-smoke halogen-free polyolefin cable material and preparation method thereof

A polyolefin cable material, metallocene polyethylene technology, used in circuits, electrical components, plastic/resin/wax insulators and other directions, can solve the problems of large smoke volume and high smoke toxicity, and achieve low and high smoke toxicity The light transmittance is small and the amount of flue gas is small, and the effect of reducing the heat of combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing a low-smoke halogen-free polyolefin cable material, which includes the following steps: mixing the formulation components described in any one of the present invention, banburying, extruding and granulating, and drying to obtain Low-smoke halogen-free polyolefin cable compound.

[0040] In one of the examples, all the components measured by weight in the above formula are mixed evenly and banburyed to 150°C, and then granulated by twin-screw extrusion at a melt extrusion temperature of 120-150°C. After drying, the high Low light transmittance low toxicity low smoke halogen free polyolefin cable compound.

Embodiment 1-4

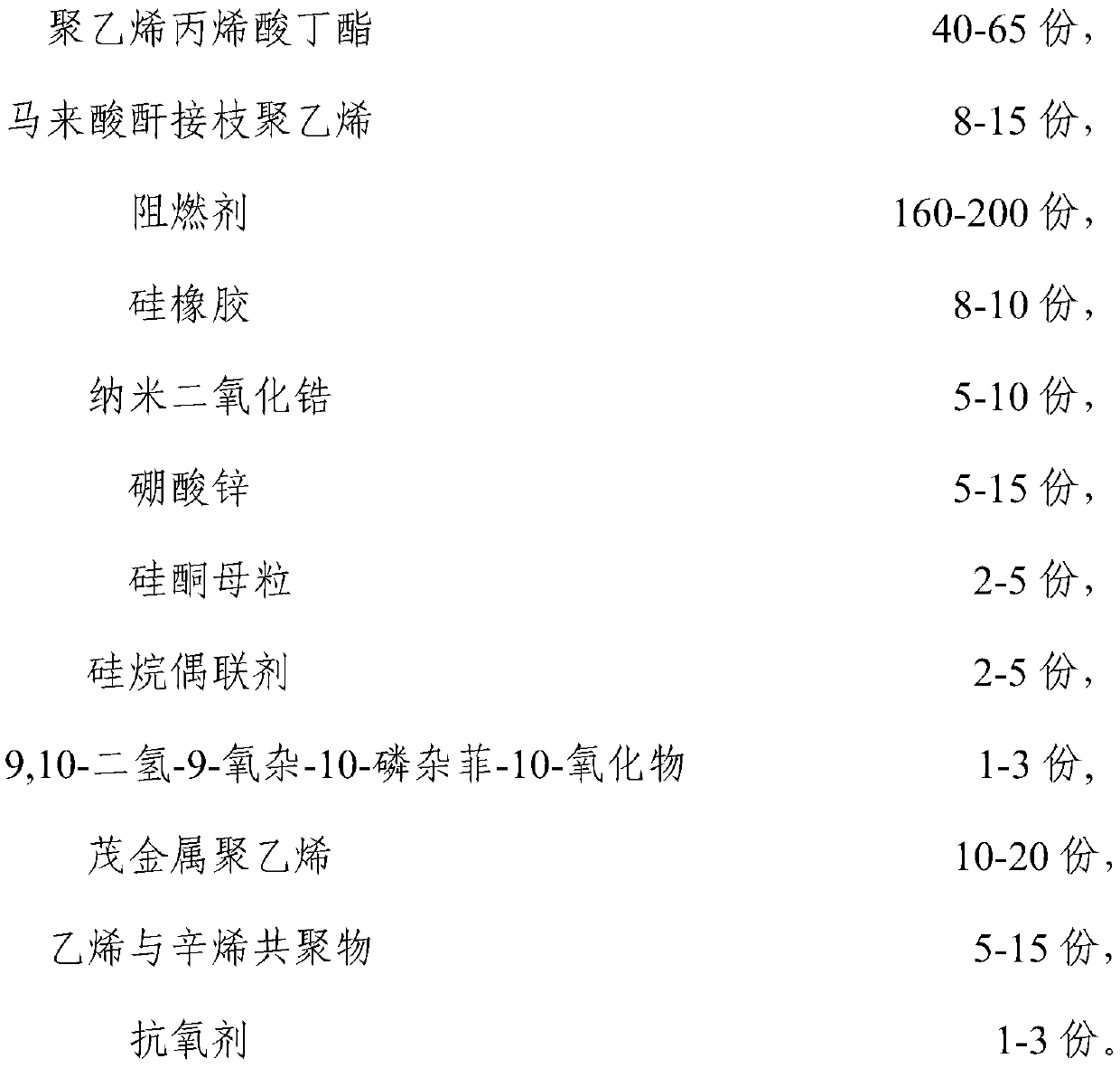

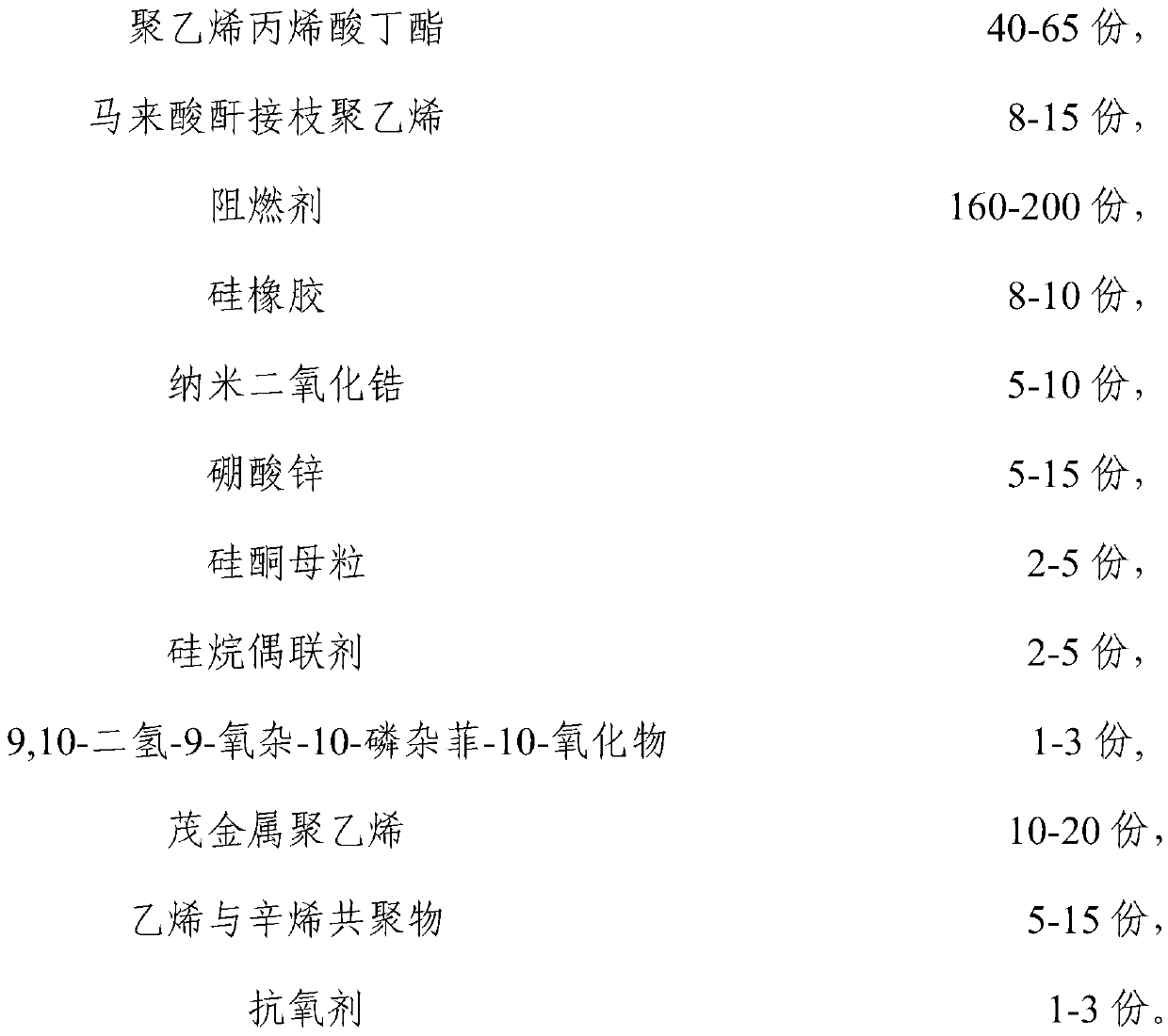

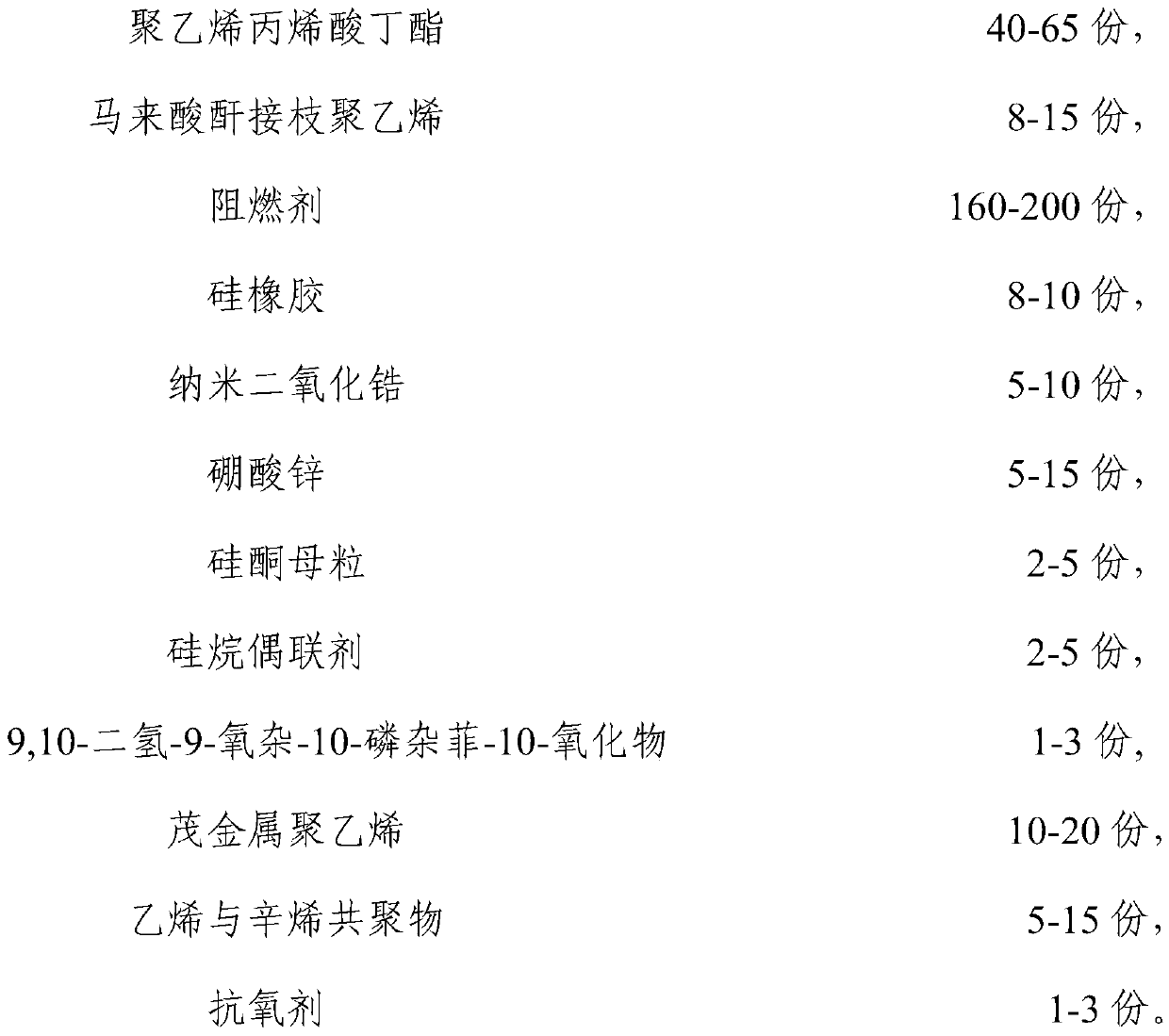

[0043] The formulation composition of the low-smoke halogen-free polyolefin cable material in Examples 1-4 of the present invention is shown in Table 1, and the consumption of each component in the table is in parts by weight.

[0044] Table 1 The formula composition of different low-smoke halogen-free polyolefin cable materials

[0045]

[0046] Raw material performance in the present invention:

[0047] The melt index of polyethylene butyl acrylate is 4g / 10min;

[0048] The melt index of metallocene polyethylene is 5g / 10min;

[0049] Ethylene and octene copolymer melt index 1g / 10min;

[0050] The graft rate of maleic anhydride grafted polyethylene is 0.8%;

[0051] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester;

[0052] After compounding aluminum hydroxide and magnesium hydroxide, the particle size is 0.8μm;

[0053] The relative molecular mass of methyl vinyl silicone rubber is 1.2 million;

[0054] Nano zirconi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap