Performance identification test method for high-reliability rubber expansion joint

A rubber expansion and identification test technology, which is applied in the field of rubber expansion joints, can solve the problems of not being localized, single test methods, and large deviations, and achieve the effects of saving test time, improving safety performance, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

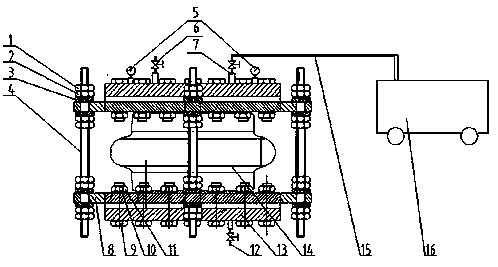

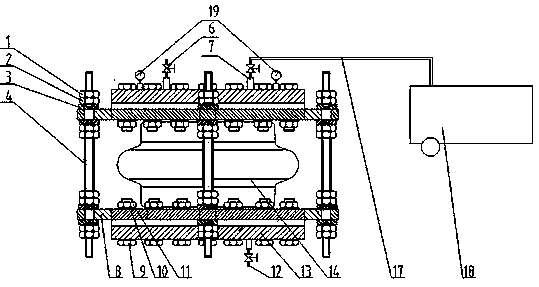

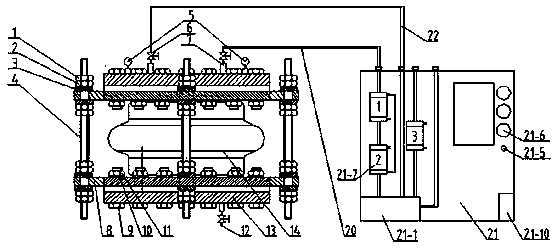

Image

Examples

Embodiment approach 1

[0056] Embodiment 1 is Step 8: In the embodiment of dynamic displacement test, keep the initial positions of the main hydraulic ejector rod 92 for axial displacement, the auxiliary balance hydraulic ejector rod 93 for axial displacement and the hydraulic ejector rod 99 for angular displacement fixed, and set the diameter To the test radial displacement (actual maximum radial displacement) of displacement hydraulic mandrel a95 and (or) radial displacement hydraulic mandrel b96, fill the test rubber expansion joint with 110°C test water and keep the test pressure at The test pressure is 1.5 times the design pressure, set the test movement frequency and the number of fatigue tests (200,000 times in the embodiment), and you can choose the radial displacement hydraulic ejector rod a95 and (or) the radial displacement hydraulic ejector rod b96 at the same time Radial displacement action test, or only test in one direction;

Embodiment approach 2

[0057] The second implementation mode is step 9: the implementation mode of the seismic test, using the "single frequency sweep output" test mode, setting the single motion frequency and the number of motions to be tested, and setting the radial displacement to be tested (maximum design radial displacement amount), click "Start" to enter the single-frequency automatic test mode.

[0058] Step 7, simulated working condition test

[0059] Put the two ends of the test rubber expansion joint 14 respectively and the test blocking plate 13 through the screw holes with bolts, insert gaskets and nuts, and tighten them symmetrically and sequentially to ensure that the sealing surface does not leak. When assembling, ensure that the bottom plane of the test blocking plate 13 is at In the same plane, set the installed one-end test blocking plate 13 on the test platform 71 with fixing bolts, insert the two ends of the limit pull rod 4 into the limit pull rod nut and the limit pull rod gasket...

specific Embodiment approach

[0085] The anti-pressure test is a verification test for the integrity of the compression resistance before blasting of the qualified test rubber expansion joint that has completed all the above-mentioned superimposed test items and remains intact; the specific implementation method is as follows:

[0086] Adopt step 7: Simulate the installation and connection method of the working condition test, keep the axial tension to the displacement required by the test (the maximum design axial elongation displacement) and use the limit rod to limit and fix the position; add the test rubber expansion joint inside Note the test medium that meets the test requirement temperature (the embodiment is usually the test temperature of 110°C), and keep the temperature constant, adjust the frequency conversion booster pump 75 and the test medium outlet valve so that the test medium pressure inside the test rubber expansion joint is 1 times the design. Under pressure, run the test at constant pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com