Nano-structured catalyst capable of activating multiple catalytic effects, and application thereof

A nanostructure and catalyst technology, which is used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst activation/preparation, etc., to achieve the effects of easy operation, improved catalytic degradation ability, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

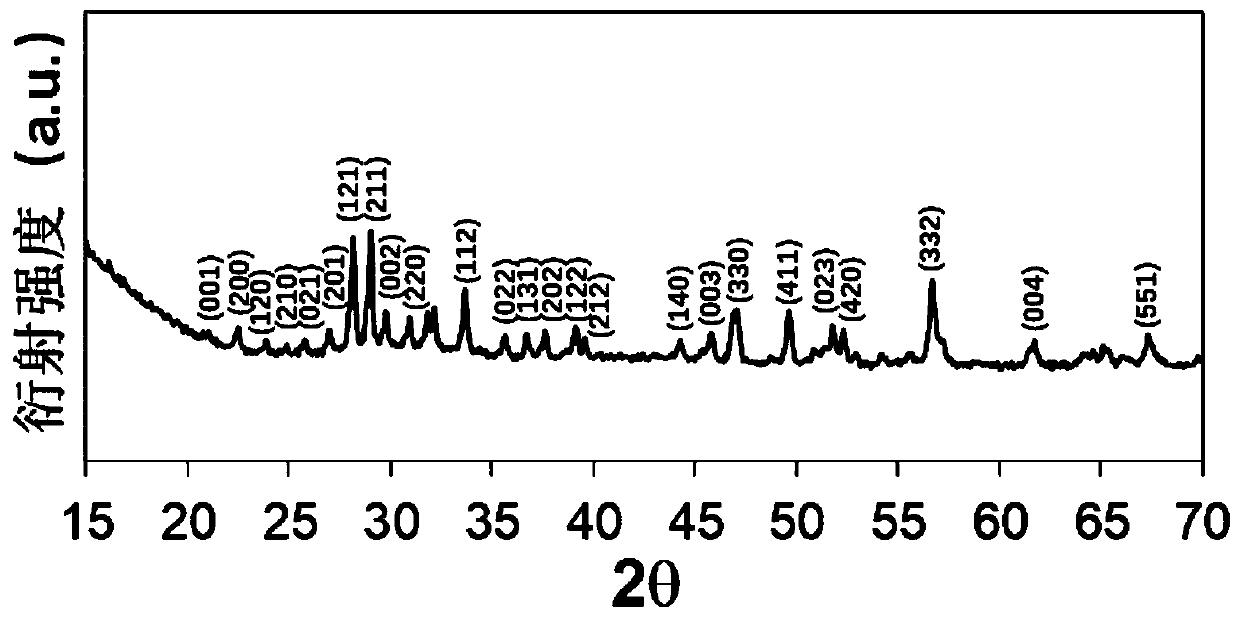

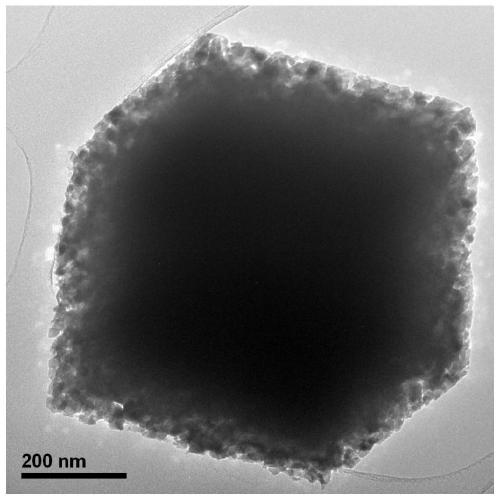

[0034] Example 1 Preparation of cubic bismuth ferrite nanostructured cluster catalysts for activating various catalytic effects (S1 sulfate radical activation catalysis, S2 visible light-Fenton catalysis, S3 visible light photocatalysis), and applied to water form Degradation of base orange pollutants.

[0035] Prepare cubic bismuth ferrite nanostructured cluster body catalyst, the steps are as follows:

[0036] 1) Dissolve 16g of citric acid in 30mL of deionized water to prepare citric acid solution A. 6.05g Bi(NO 3 ) 3 ·5H 2 O, 10.61g Fe(NO 3 ) 3 9H 2 O dissolved in 5 mL of 2M HNO 3 In the aqueous solution, mix with the citric acid solution A prepared above, and stir for 15 minutes so that the citric acid in the mixed solution interacts with the Bi / Fe ions to form a trinuclear Bi / Fe-citrate complex;

[0037] 2) Add 180mL of 12M NaOH aqueous solution to the mixed solution obtained in step 1) under vigorous stirring, and stir for 30 minutes to convert the trinuclear Bi...

Embodiment 2

[0055] To prepare a cuboid-shaped bismuth ferrite nanostructured cluster catalyst, the preparation steps were repeated in Example 1, except that "the hydrothermal reaction time in step 4) was adjusted to 20 minutes", and the remaining conditions were the same as in Example 1. Finally, a bismuth ferrite nanostructured cluster catalyst is prepared.

[0056] The SEM figure of the bismuth ferrite nanostructured cluster body catalyst prepared in embodiment 2 is as follows Figure 4 shown. From Figure 4 It can be seen that the bismuth ferrite nanostructured catalyst presents a uniform nanocuboid structure with a side length of ~230 nm and a height of ~600 nm, with high uniformity and narrow size distribution. The nanostructured cluster body has a relatively high specific surface area, which is beneficial to improving its catalytic activity.

[0057] S1 Sulfate Activation Catalysis: The bismuth ferrite nanostructured cluster catalyst prepared in Example 2 cooperates with PMS to f...

Embodiment 3

[0061]To prepare a square plate-shaped bismuth ferrite nanostructured cluster catalyst, the preparation steps were repeated in Example 1, except that "the hydrothermal reaction time in step 4) was adjusted to 60 minutes", and the rest of the conditions were the same as in Example 1 , and finally a bismuth ferrite nanostructured cluster catalyst was prepared.

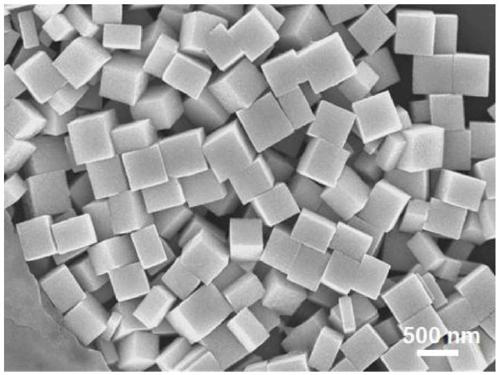

[0062] The SEM image of the bismuth ferrite nanostructured catalyst prepared in embodiment 3 is as follows Figure 5 shown. From Figure 5 It can be seen that the bismuth ferrite nanostructured cluster catalyst presents a uniform nanosquare plate-like structure with a side length of ~380 nm and a thickness of ~80 nm. The cluster body of the nano-plate structure has a relatively high specific surface area, which is beneficial to improving its catalytic activity.

[0063] S1 Sulfate Activation Catalysis: The square plate-shaped bismuth ferrite nanostructured cluster catalyst prepared in Example 3 cooperates with PMS to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com