A kind of ferrous disulfide and its preparation method using mof as precursor

A ferrous disulfide, precursor technology, used in the preparation/purification of iron sulfide, carbon, secondary batteries, etc., can solve problems such as poor conductivity restricting the development of electrode materials, and achieve good electrochemical performance, pore structure and conductivity. The effect of adjustable resistance and improved cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

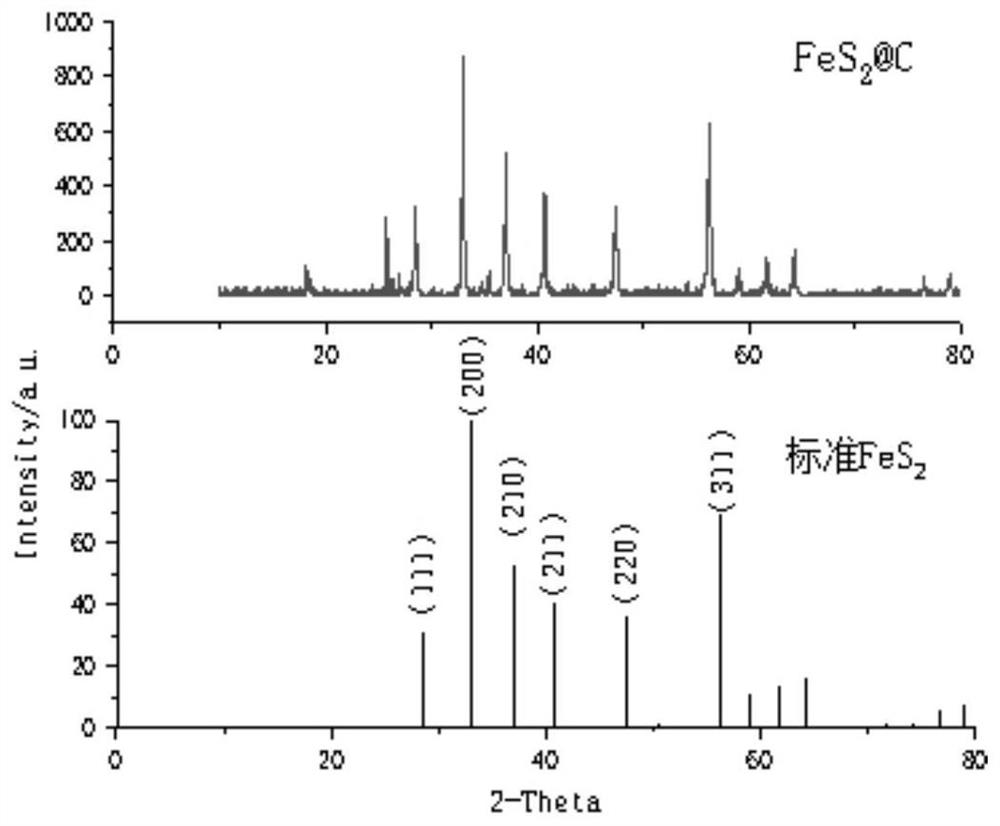

[0033] A kind of preparation method of ferrous disulfide taking MOF as template, concrete steps are as follows:

[0034] Step 1: Dissolve the iron salt, carbon source and precipitant in deionized water according to the molar ratio of Fe, carbon source and precipitant as 1:1.5~2:1.6~2, stir evenly, and then disperse a certain molar amount Put the agent into the uniformly stirred solution, stir and mix evenly, transfer the solution to the reaction kettle, and keep it warm at 160-180°C for 12h. Then the obtained black suspension was centrifuged and washed with deionized water and ethanol to obtain a black powder, which was dried in a vacuum oven at 60° C. for 8-12 hours to obtain an iron-based precursor.

[0035] Step 2: According to the molar ratio of iron and carboxylic acid as 2:1, dissolve the iron-based precursor and carboxylic acid obtained in step 1 in DMF, transfer the prepared solution to the reaction kettle, and keep it warm at 110-120°C After 16-20 hours, fully wash w...

Embodiment 1

[0041] Step 1: Dissolve 0.0082mol ferric chloride hexahydrate, 0.0131mol urea, and 0.0123mol sodium citrate in 100mL deionized water, place on a magnetic stirrer and stir for 30 minutes until fully dissolved, then add 0.6g PVP and stir for 1 hour, after completely dissolving The solution was transferred to a reaction kettle and kept in an oven at 180°C for 12h. Then the obtained black suspension was centrifuged and washed with deionized water and ethanol to obtain a black powder, which was dried in a vacuum oven at 60° C. for 12 hours to obtain an iron-based precursor.

[0042] Step 2: Dissolve 0.004mol of iron-based precursor and 0.002mol of terephthalic acid in 120mL of N,N-dimethylformamide (DMF), stir until dissolved and transfer to the reaction kettle, the oven condition is 110°C , 20h, after the material was taken out, it was fully washed with deionized water and absolute ethanol, and then dried in a vacuum oven at 150°C for 8h to obtain orange MIL-101-Fe.

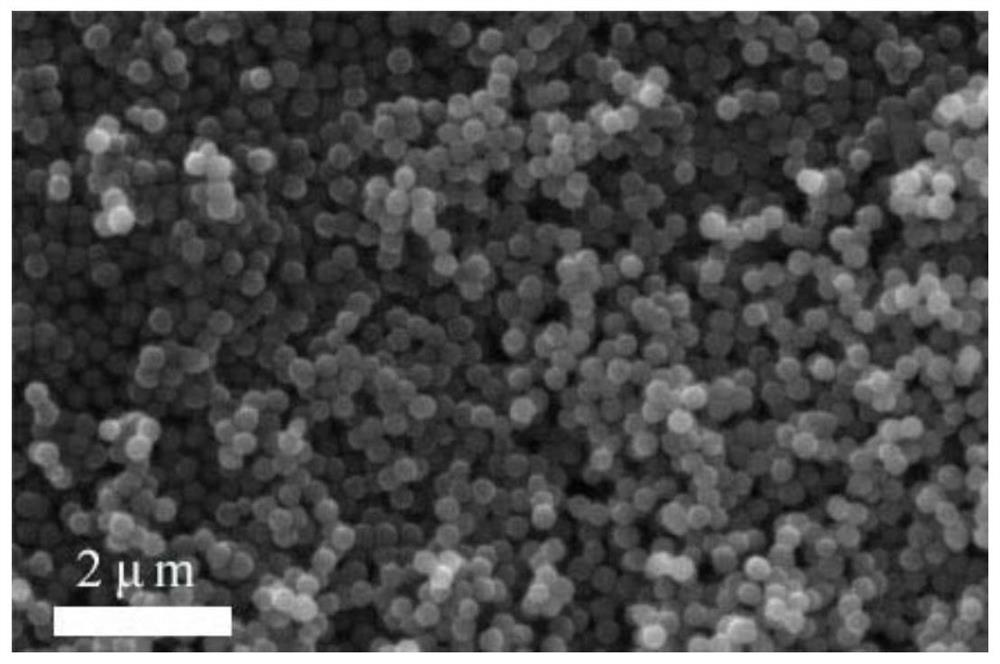

[0043] Step...

Embodiment 2

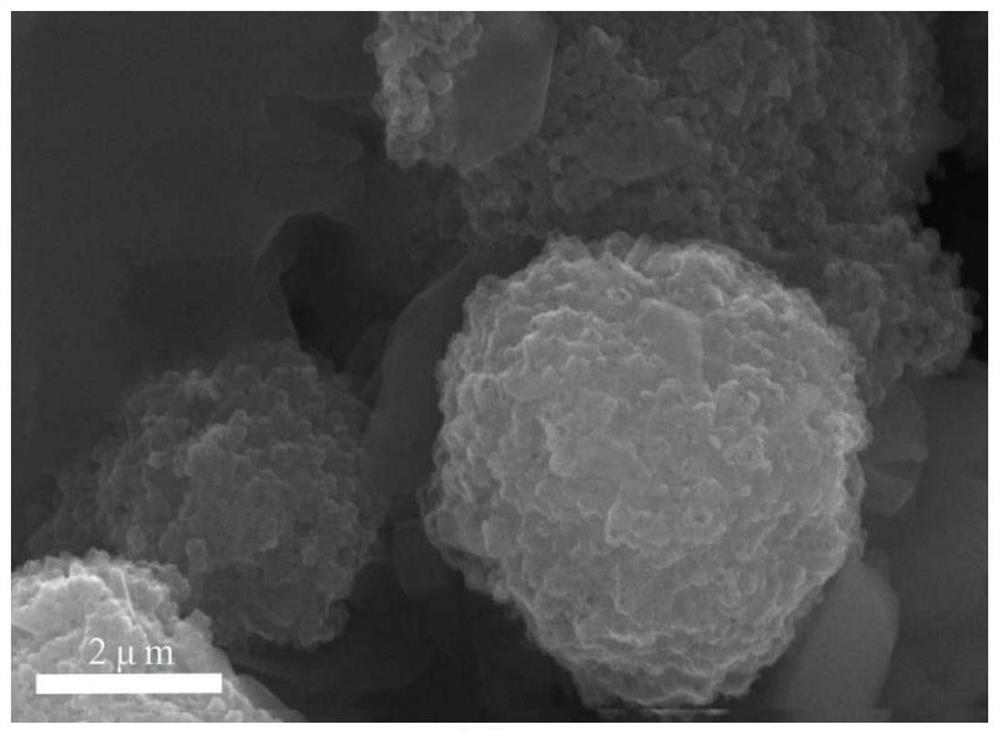

[0046] Similar to Example 1, the difference is that the vulcanization temperature in step 3 is changed to 500°C, and the scanning electron microscope characterization is as follows image 3 As shown, the diameter of the particles is about 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com