Intelligent oxidation system and method for preparing terephthalic acid from p-xylene

A technology of terephthalic acid and oxidation system, applied in the field of oxidation reaction, can solve the problems of reduced benefit, large consumption of acetic acid, high control requirements, etc., to reduce operating temperature and pressure, increase safety and stability, and increase phase. The effect of boundary area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

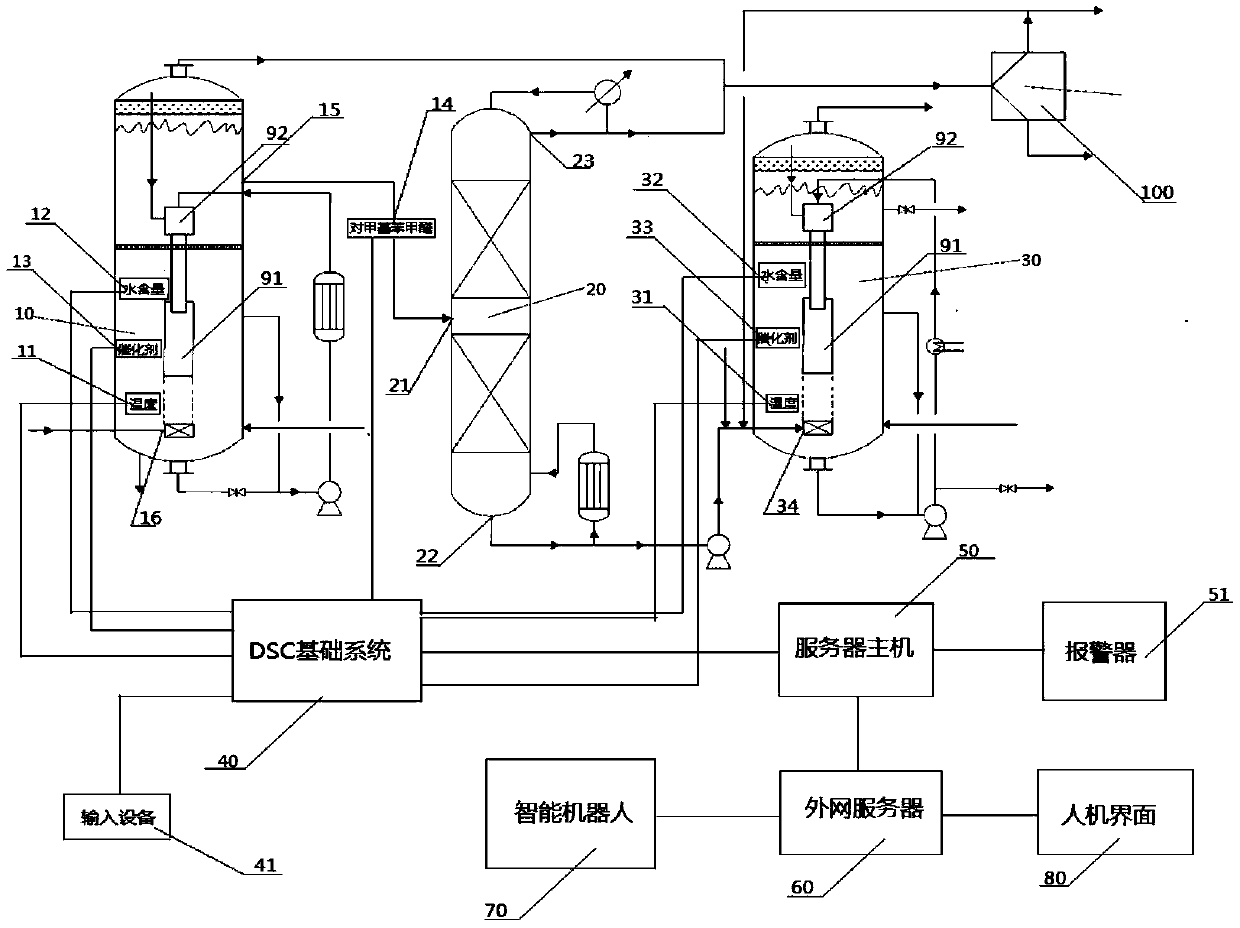

[0072] refer to figure 1 As shown, the intelligent oxidation system for preparing terephthalic acid from p-xylene includes a first reactor 10, a rectification tower 20, a second reactor 30, a DSC basic system 40, a server host 50, an external network server 60 and Intelligent Robot 70.

[0073] On-site sensors are connected to the DSC basic system 40, and the on-site sensors include a first temperature sensor 11, a first water content sensor 12, and a first catalyst concentration sensor 13 arranged inside the first reactor 10, and a first temperature sensor 13 arranged inside the second reactor 30. Two temperature sensors 31 , a second water content sensor 32 and a second catalyst concentration sensor 33 , and the field sensors also include a p-tolualdehyde content sensor 14 arranged on the pipeline between the first outlet 15 and the material inlet 21 .

[0074] The real-time measurement data of all on-site sensors are transmitted to the DSC basic system 40 through the HART ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com