Preparation method of blue mullite

A moissanite and blue technology, applied in the field of moissanite preparation, can solve the problems of light color of moissanite, uncontrollable release speed of doping substances, poor uniformity of moissanite crystal color, etc., and achieve simple and controllable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

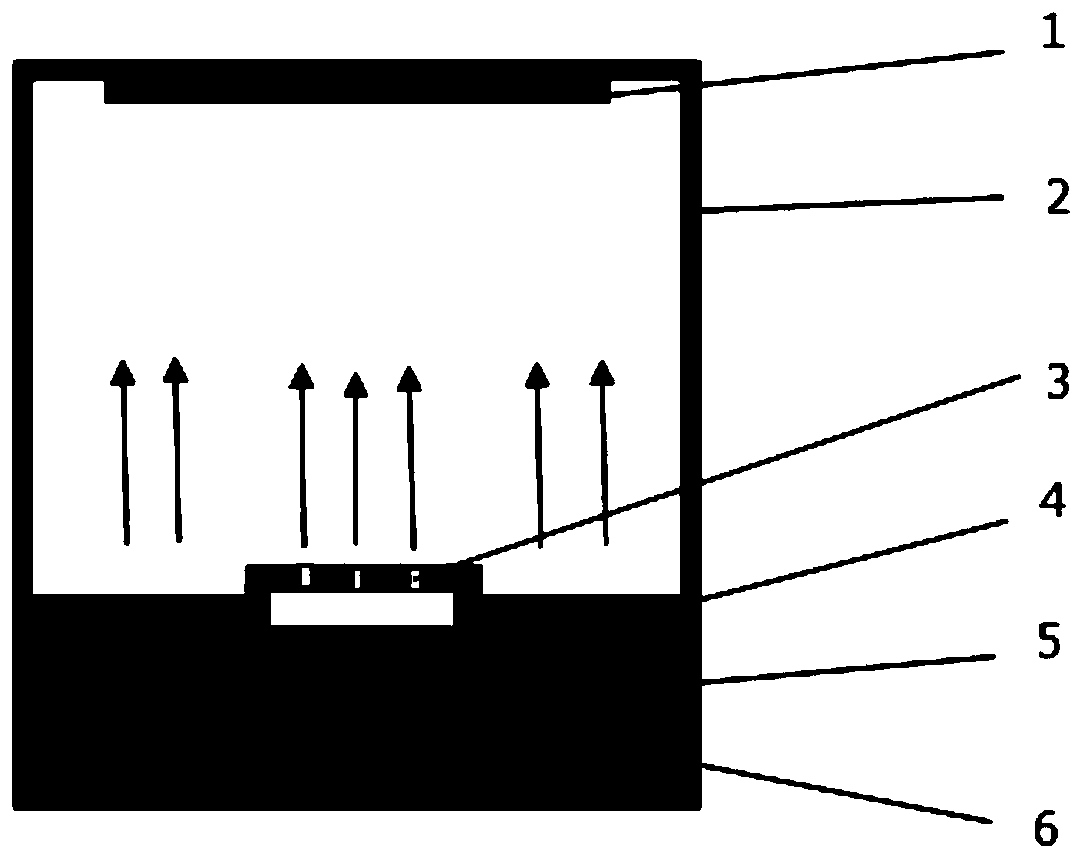

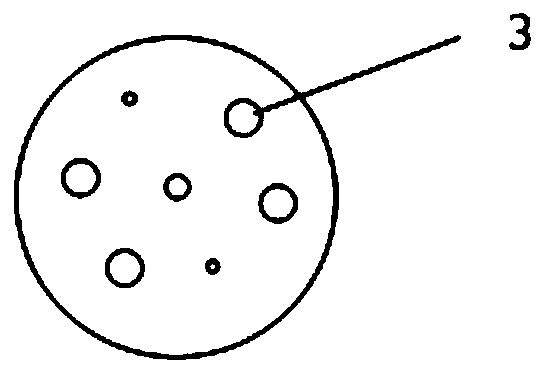

[0026] In order to solve the above technical problems, the technical solution adopted in the present invention is: Figure 1-2 Shown, a kind of preparation method of blue Moissanite comprises the following steps:

[0027] Step (1), high-purity silicon carbide powder 6 is mixed evenly with doped metal aluminum or aluminum-containing compound, put into high-purity graphite crucible 2, moissanite polycrystal is fixed on the inner side of graphite crucible cover as seed crystal 1, and graphite is sealed The crucible is put into the crystal growth furnace and grown by physical vapor transport method.

[0028] According to a specific embodiment of the present invention, the purity of the silicon carbide powder is not less than 99.99%. According to some specific embodiments of the present invention, the doped metal aluminum or aluminum-containing compound is one or more of simple metal aluminum, aluminum nitride or aluminum phosphide. According to some specific embodiments of the p...

specific Embodiment 1

[0034] A method for preparing blue moissanite according to the present invention realizes the preparation of blue moissanite by doping metallic aluminum or aluminum-containing compounds, and controls the uniformity of doping metallic aluminum by a secondary crystallization method combined with an inner crucible device And then get blue moissanite with uniform color. Concrete preparation steps are:

[0035] Step (1), high-purity silicon carbide powder and doped metal aluminum nitride are evenly mixed, put into a high-purity graphite crucible, moissanite polycrystal is fixed on the inner side of the graphite crucible cover as a seed crystal, the graphite crucible is sealed, and the crystal is placed In the growth furnace, the physical vapor transport method is used for growth; the uniform mixing method is a ball milling method; the seed crystal fixing method is bonding and fixing.

[0036] Step (2), after cooling down, take out the aluminum-doped moissanite polycrystal, pulveri...

specific Embodiment 2

[0041]The difference from specific example 1 is that in the step (1), the aluminum-containing compound is metal elemental aluminum; the seed crystal is fixed by mechanical fixation; in the step (2), the cooling speed 50°C per hour; the micropore size of the graphite inner crucible cover is 50 microns. In the step (3), the material of the single crystal moissanite is 6H-type moissanite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com