Chromium-titanium alloy treatment method and application of chromium-titanium alloy treatment method in metallographic structure display

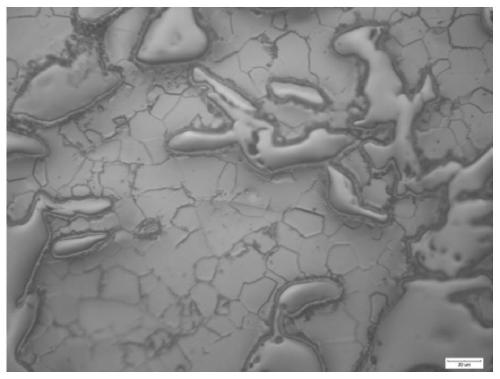

A technology of chromium-titanium alloy and processing method, which is applied in the field of material corrosion, can solve the problems of poor metallographic structure display effect, uncontrollable, uneven dyeing, etc., and achieve the effect of good display effect, improved flatness, and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment provides a chromium-titanium alloy processing method, the method comprising the following steps:

[0050] (1) Take the chromium-titanium alloy target blank, use 400# water-based sandpaper, 1000# water-based sandpaper and 2000# water-based sandpaper to mechanically polish in sequence, and use water as a wetting agent, and polish for 5 minutes until the surface is bright;

[0051] (2) Immerse the mechanically polished chromium-titanium alloy in the electrolytic polishing solution, perform electrolytic corrosion at a voltage of 42V, keep the temperature at 25°C for 55s, and form a corrosion surface;

[0052] The electrolytic polishing liquid comprises perchloric acid, ethanol, n-butanol and water;

[0053] Taking the volume of the polishing liquid as 100%, the volume fraction of the perchloric acid is 5%, the volume fraction of the ethanol is 65%, the volume fraction of the n-butanol is 5%, and the volume fraction of the water The volume fraction is...

Embodiment 2

[0055] The present embodiment provides a chromium-titanium alloy processing method, the method comprising the following steps:

[0056] (1) Take the chromium-titanium alloy target blank, use 400# water-based sandpaper, 1000# water-based sandpaper and 2000# water-based sandpaper to perform mechanical polishing in sequence, use water as a wetting agent, polish for 8 minutes until the surface is bright, and rinse the mechanically polished chrome with water Titanium alloy surface, blow dry;

[0057] (2) Immerse the mechanically polished chromium-titanium alloy in the electrolytic polishing solution, perform electrolytic corrosion at a voltage of 42V, keep the temperature at 25°C for 55s, and form a corroded surface, take out the electrolytically etched chromium-titanium alloy, rinse it with water, blow Dry;

[0058] The electrolytic polishing liquid comprises perchloric acid, ethanol, n-butanol and water;

[0059] Taking the volume of the polishing liquid as 100%, the volume fra...

Embodiment 3

[0061] The present embodiment provides a chromium-titanium alloy processing method, the method comprising the following steps:

[0062] (1) Take the chromium-titanium alloy target blank, use 400# water-based sandpaper, 1000# water-based sandpaper and 2000# water-based sandpaper to perform mechanical polishing in sequence, use water as a wetting agent, polish for 8 minutes until the surface is bright, and rinse the mechanically polished chrome with water Titanium alloy surface, drying;

[0063] (2) Immerse the mechanically polished chromium-titanium alloy in the electrolytic polishing solution, perform electrolytic corrosion at a voltage of 42V, keep the temperature at 25°C for 55s, and form a corroded surface, take out the electrolytically etched chromium-titanium alloy, and rinse it with water. drying;

[0064] The electrolytic polishing liquid comprises perchloric acid, ethanol, n-butanol and water;

[0065] Taking the volume of the polishing liquid as 100%, the volume fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com