Method for oxidizing TMB by taking nano cerium dioxide as simulated oxidase

A nano-ceria, oxidase technology, applied in nanotechnology, chemical analysis by catalysis, material analysis by observing the impact on chemical indicators, etc., to achieve simple synthesis steps, easy reaction temperature, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

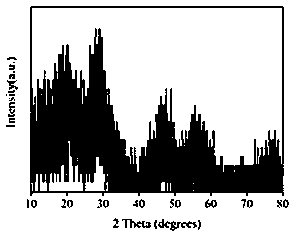

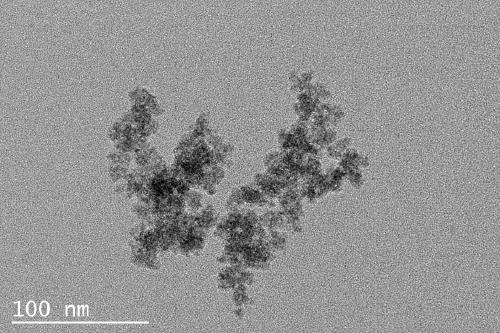

[0022] Dissolve 0.22 g of cerium sulfate tetrahydrate and 0.3 g of sodium hydroxide in 50 ml of deionized water, respectively. Dissolve polyvinylpyrrolidone in cerium sulfate tetrahydrate solution, and stir continuously at room temperature for 30 minutes until polyvinylpyrrolidone is completely dissolved. Add sodium hydroxide solution dropwise to the above solution, continue to stir at room temperature for 30 minutes, centrifuge, wash with deionized water and absolute ethanol three times, and dry at 30°C to obtain a light yellow powder.

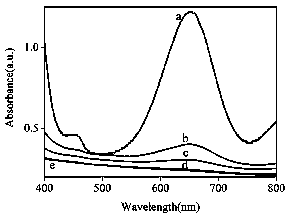

[0023] The nano-cerium oxide obtained in the above examples was used to catalyze the TMB color reaction, and the specific implementation was as follows: 16 mg of TMB was dispersed in 7.5 ml of a series of pH gradients (pH gradients were 5.4, 6.0, 6.4, 7.0, 7.4) In the phosphate buffer solution, the solution system I was formed; 1.6 mg of the nano-cerium oxide simulated oxidase prepared in the example was added to the solution II, slightly sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com