Desulfurization, denitrification and white smoke elimination device for ultralow emission of sintering machine flue gas and process thereof

A technology of desulfurization and denitrification, sintering machine, applied in the direction of combination device, gas treatment, membrane technology, etc., can solve the problems of SCR flue gas denitrification device can not run normally for a long period of time, high operating cost, high smoke concentration, etc., to achieve good dust removal and fog removal effect, avoid poisoning or clogging, effect with small fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

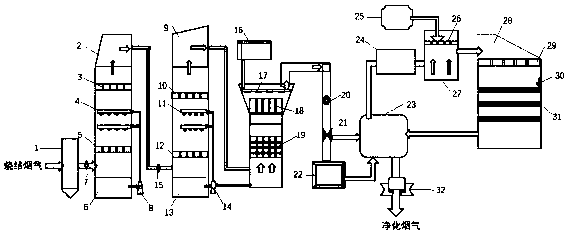

[0046] Such as figure 1 As shown, the present invention provides a desulfurization, denitrification and whitening device for ultra-low emission of sintering machine flue gas, including: bag filter 1, primary desulfurization tower 2, secondary desulfurization tower 9, swirl type dust and mist eliminator 19. Wet electrostatic precipitator 18, dry desulfurizer 22, heat exchanger 23, flue gas heater 24, premixer 27, SCR denitrification reactor 28;

[0047] Among them, the bag filter 1 receives the sintering flue gas and communicates with the first-level desulfurization tower 2, the first-level desulfurization tower 2 includes the first-level desulfurization tower demister 3, the first-level desulfurization tower spray pipe 4, and the first-level desulfurization tower deflector 5, and communicate with the secondary desulfurization tower 9 in sequence; meanwhile, the lower part of the primary desulfurization tower 2 has a primary desulfurization tower slurry tank 6, and the primary ...

Embodiment 2

[0063] The desulfurization, denitrification and whitening device described in Example 1 for the ultra-low emission of sintering machine flue gas was used in the emission experiment of sintering flue gas, and the treatment of sintering flue gas in Baosteel Iron and Steel Plant was specifically tested. After running for one month, every week Test NOx, SO2, and dust concentration. After testing, it is found that after using the device described in Example 1 and related processes to treat sintering flue gas, the structures tested every week meet the ultra-low emission standard, NOx≤50mg / Nm 3 , SO2 concentration is ≤35mg / Nm 3 , the dust concentration is ≤10mg / Nm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com