Manufacturing method of layered aluminum-aluminum-base composite material plate

An aluminum-based composite material, layered technology, applied in the direction of metal rolling, can solve the problems of cumbersome preparation work, easy welding, high cost of vacuum diffusion welding, simple preparation method, improved comprehensive performance, material shape and size. easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

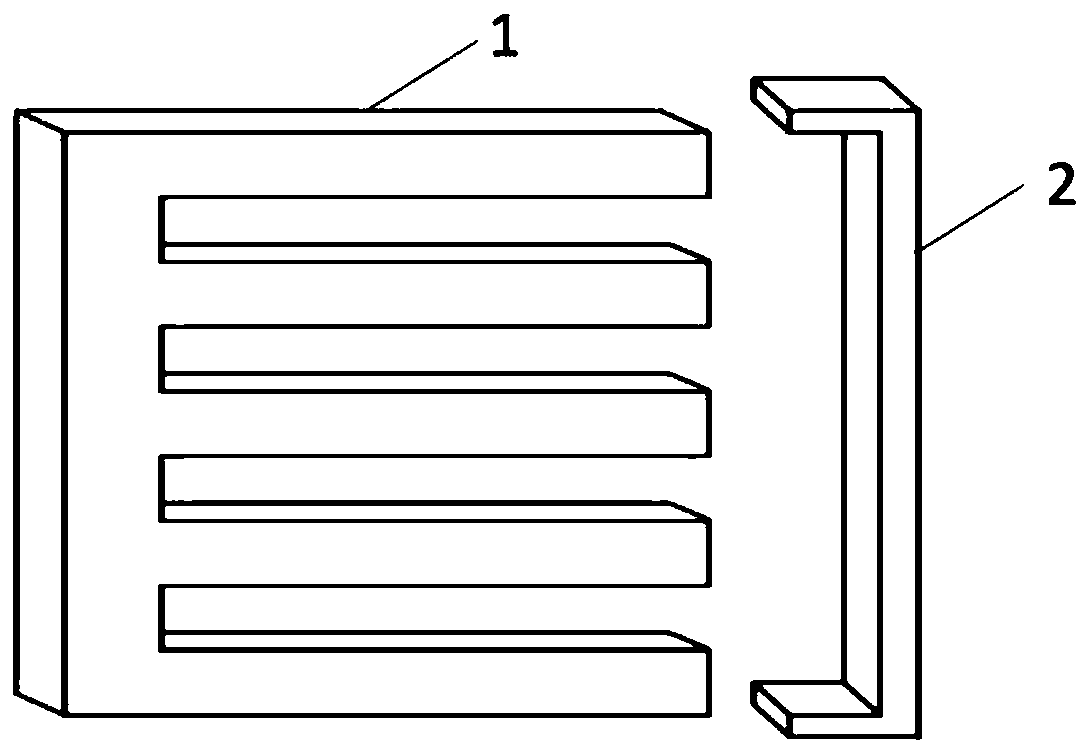

[0024] The preparation method of the above-mentioned layered aluminum-aluminum matrix composite material plate is characterized in that it comprises the following steps:

[0025] (1) Firstly, the Al3BC / 6061 aluminum-based composite material is processed into shapes with different numbers of grooves by wire-cut electric discharge machine, which are used as "casting molds", and then the bonding interface is sanded-washed-acetone ultrasonic cleaning- Water washing—pickling—rewashing step, and finally dry quickly, and protect the surface with inert gas to ensure that the contact surface has a certain roughness, oil-free and clean, which is conducive to the bonding of the interface.

[0026] (2) Melting the aluminum ingot at a temperature range of 650°C to 680°C.

[0027] (3) After the "mold" is heated to 500°C, the molten liquid is cast into the mold and cooled to obtain a layered composite sheet.

[0028] (4) Cut off part of the Al3BC / 6061 aluminum-based composite material at th...

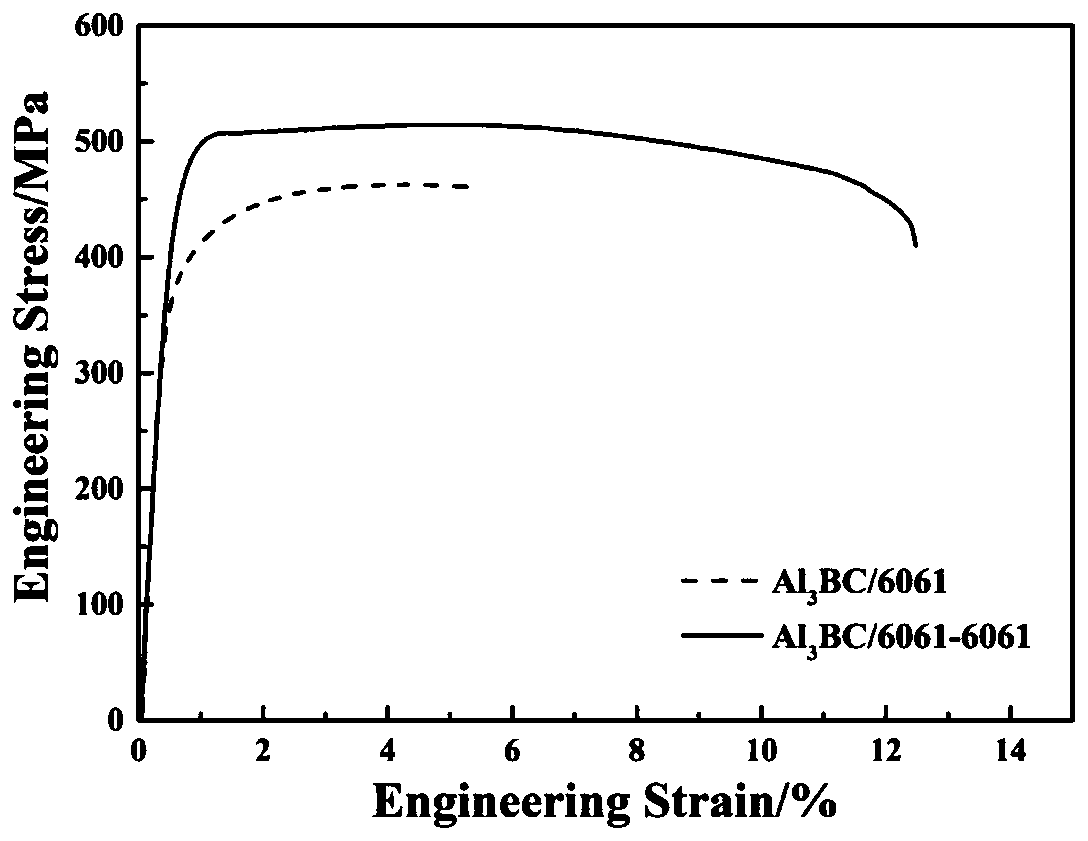

Embodiment 1

[0031] (1) Al 3 The BC / 6061 aluminum-based composite material is processed into a "casting mold" with 4 grooves by a wire-cut electric discharge machine, and the joint interface is sanded-washed-acetone ultrasonic cleaning-water-washed-pickling-rewashing steps, Finally, dry quickly and protect the surface with inert gas to ensure that the contact surface has a certain roughness, oil-free and clean, which is conducive to the bonding of the interface.

[0032] (2) Melt the 6061 aluminum alloy at a temperature range of 650°C.

[0033] (3) After the "mold" is heated to 500°C, the molten liquid is cast into the mold and cooled to obtain a composite plate with 9 layers.

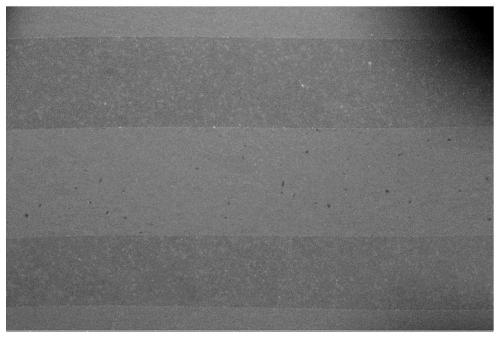

[0034] (4) The edge Al of the obtained layered composite sheet 3 Part of the BC / 6061 aluminum-based composite material is cut off and rolled at room temperature by 80%, which further strengthens the interfacial bonding and improves the compactness of the material.

[0035] (5) Perform low-temperature annealing t...

Embodiment 2

[0038] (1) Al 3 The BC / 6061 aluminum-based composite material is processed into a "casting mold" with 4 grooves by a wire-cut electric discharge machine, and the joint interface is sanded-washed-acetone ultrasonic cleaning-water-washed-pickling-rewashing steps, Finally, dry quickly and protect the surface with inert gas to ensure that the contact surface has a certain roughness, oil-free and clean, which is conducive to the bonding of the interface.

[0039] (2) Melt the pure aluminum ingot at a temperature of 680°C.

[0040] (3) After the "mold" is heated to 500°C, the molten liquid is cast into the mold and cooled to obtain a composite plate with 9 layers.

[0041] (4) The edge Al of the obtained layered composite sheet 3 Part of the BC / 6061 aluminum-based composite material is cut off and rolled at room temperature by 80%, which further strengthens the interfacial bonding and improves the compactness of the material.

[0042] (5) Perform low-temperature annealing treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com