Aerobic carrier for domestic sewage treatment, and preparation method and application thereof

A domestic sewage and oxygen carrier technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of poor biological affinity, low removal rate of ammonia nitrogen, easy biofilm shedding, etc. problem, to achieve enhanced material exchange, large specific surface area, and good bioaffinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

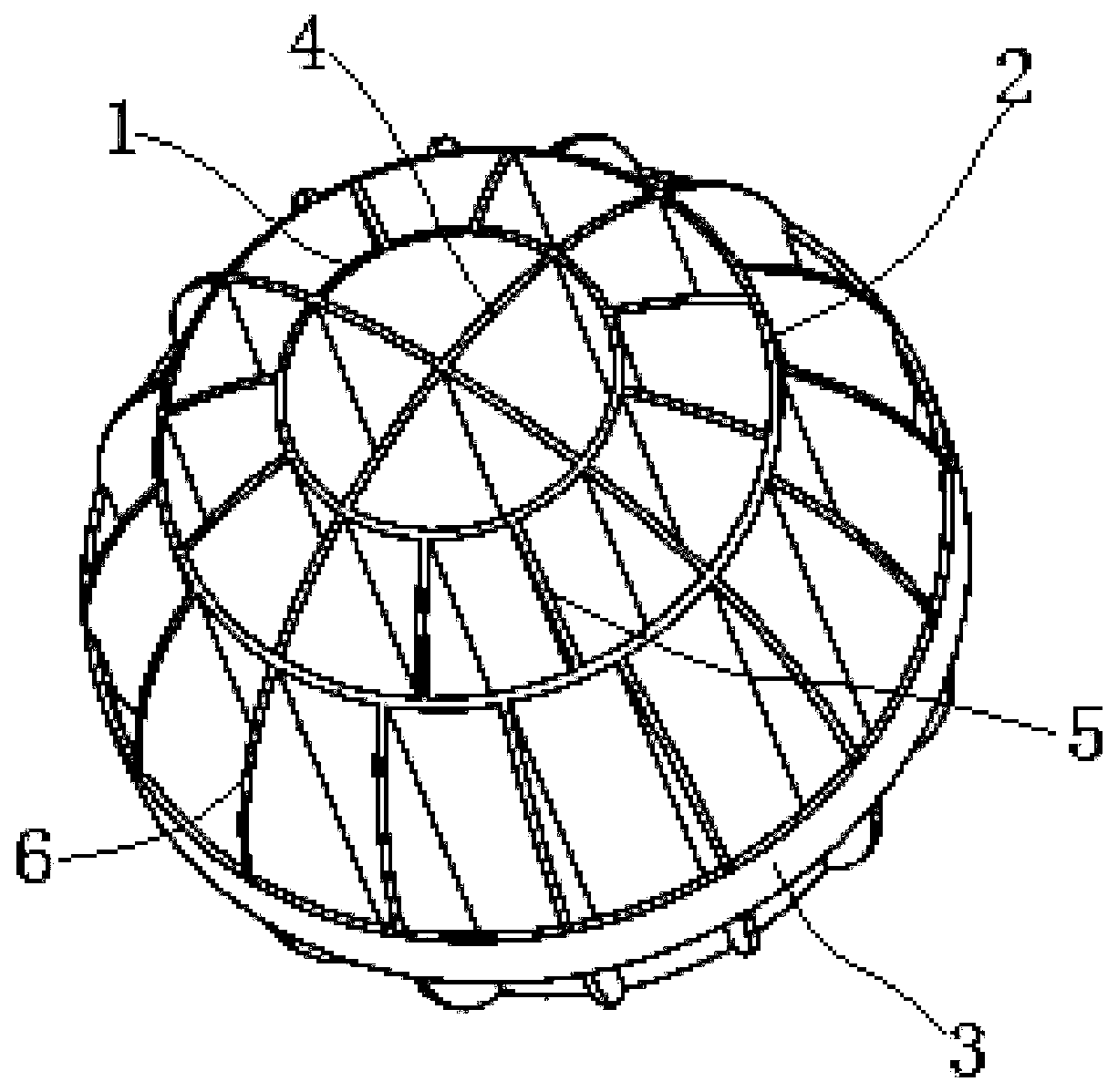

[0036] refer to figure 1, an aerobic carrier for domestic sewage treatment, comprising a first cylinder body 1, a second cylinder body 2, and a third cylinder body 3 with successively increasing diameters and successively decreasing heights, and also includes first connecting ribs 4, second A connecting rib 5 and a third connecting rib 6; both ends of the cylinder are open, and the connecting ribs are plate-shaped.

[0037] For the first cylindrical body 1, its outer diameter is 20mm, and its height is 54mm. Four first connecting ribs 4 are fixed on the inner wall of the first cylindrical body to form the connecting ribs of the "ten" shape structure and the "ten" shape The intersecting center of the connecting ribs of the structure coincides with the axis of the first cylindrical body.

[0038] As for the second cylinder 2, its outer diameter is 40 mm and its height is 40 mm. The outer wall of the first cylinder and the inner wall of the second cylinder are fixedly connected ...

no. 2 example

[0042] An aerobic carrier for domestic sewage treatment is different from the first embodiment in that the outer diameter of the third cylinder is 50 mm, the outer diameter of the second cylinder is 30 mm, and the outer diameter of the third cylinder is 15 mm. The height of the first cylinder is 50mm, the height of the second cylinder is 35mm, and the height of the third cylinder is 8mm. There are 8 connecting ribs between the first cylinder and the second cylinder, and 4 connecting ribs in the first cylinder. There are 16 connecting ribs between the second cylinder body and the third cylinder body.

no. 3 example

[0044] A preparation of an aerobic carrier for domestic sewage treatment, comprising the steps of: taking 1.5kg of silicon dioxide micropowder whose particle size is above 200 mesh, 0.8kg of carbon black, 3kg of talcum powder, 15kg of maleic anhydride grafted polypropylene, polypropylene 80kg of propylene, put them in an oven at 105°C, take them out after drying for 6 hours, then put all the above materials in a high-speed mixer and mix them evenly, then put them in a twin-screw extruder, extrude and granulate at 175°C , after the pellets are cooled, they are placed in an injection molding machine for molding, and after cooling, they are demolded to obtain figure 1 The shown aerobic carrier for domestic sewage treatment has a carrier contact angle of 89.4° and a density of about 0.94g / cm 3 .

[0045] Take a container with a volume of 200L, fill it with the aerobic carrier prepared by using modified materials in this example according to the filling rate of 40%, weigh the tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com