Magnesium ion doped carbon quantum dot as well as preparation and application methods thereof

A technology of carbon quantum dots and magnesium ions, which is applied in the field of magnesium ion-doped carbon quantum dots and its preparation and application, can solve the problems of uneven size distribution, poor dispersion stability, and single function, and achieve high uniformity and particle size. The effect of small, uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

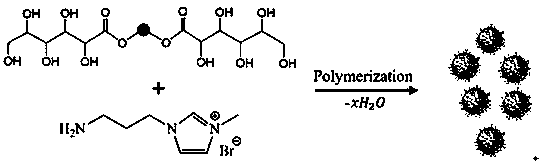

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 2g C 12 h 22 MgO 14 and 3.18g of 1-aminopropyl-3-methylimidazolium bromide (molar ratio 1:3) were added to the round bottom flask, and the flask was immersed in an oil (simethicone oil) bath at 100 °C, using magnetic force Stir (200 rpm / min) for 20 minutes to make it evenly mixed and form a gel;

[0033] (2) Immerse the round-bottomed flask in step (1) in an oil bath at 200 °C, pass through nitrogen protection, and continue to react for 2 h under magnetic stirring (500 rpm / min);

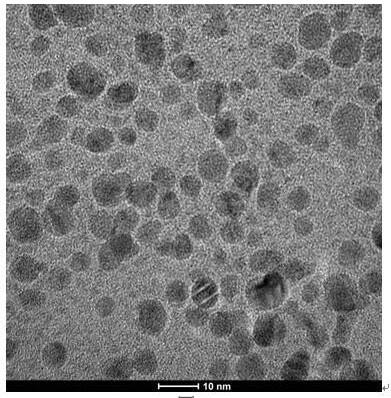

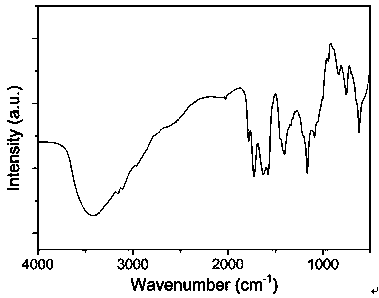

[0034](3) After the reaction is completed, cool the reaction product of step (2) to room temperature, add 20 mL of ultrapure water, and completely dissolve the reaction product under mechanical stirring to obtain a brown-black dispersion; transfer the dispersion to a centrifuge tube , centrifuge at 12000 rpm / min for 10 min, remove the sediment at the bottom of the centrifuge tube, and keep the upper dispersion containing carbon quantum dots;

[0035] (4) Transfer the upper layer di...

Embodiment 2

[0039] (1) Add 2g C 12 h 22 MgO 14 and 1g of 1-aminopropyl-3-methylimidazolium bromide (molar ratio 1:1) were added to the round bottom flask, and the flask was immersed in an oil (methylphenyl silicone oil) bath at 102 °C, using magnetic force Stir (300 rpm / min) for 25 minutes to make it evenly mixed and form a gel;

[0040] (2) Immerse the round-bottomed flask in step (1) in an oil bath at 180 °C, pass through nitrogen protection, and continue to react for 2.5 h under magnetic stirring (300 rpm / min);

[0041] (3) After the reaction is completed, cool the reaction product of step (2) to room temperature, add 20 mL of ultrapure water, and completely dissolve the reaction product under mechanical stirring to obtain a brown-black dispersion; transfer the dispersion to a centrifuge tube , centrifuge at a speed of 10000 rpm / min for 15 min, remove the sediment at the bottom of the centrifuge tube, and keep the upper layer dispersion containing carbon quantum dots;

[0042] (4) ...

Embodiment 3

[0046] (1) will 2 g C 12 h 22 MgO 14 and 2.12 g Add 1-aminopropyl-3-methylimidazolium bromide (molar ratio 1:2) into a round bottom flask, immerse the flask in an oil bath (methyl chlorophenyl silicone oil) at 105 °C, and stir with magnetic force (400 rpm / min) Stir for 15 min to make it evenly mixed and form a gel;

[0047] (2) Immerse the round-bottomed flask in step (1) in an oil bath at 240 °C, pass through nitrogen protection, and continue to react for 4 h under magnetic stirring (400 rpm / min);

[0048] (3) After the reaction is completed, cool the reaction product of step (2) to room temperature, add 30 mL of ultrapure water, and completely dissolve the reaction product under mechanical stirring to obtain a brown-black dispersion; transfer the dispersion to a centrifuge tube , centrifuge at 8000 rpm / min for 25 min, remove the sediment at the bottom of the centrifuge tube, and keep the upper layer dispersion containing carbon quantum dots;

[0049] (4) Transfer the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com