Method for co-production of 1,3-propanediol and D-1,2,4-butanetriol

A technology of propylene glycol and Klebsiella, applied in botany equipment and methods, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of limiting xylose, high xylose price, and low conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

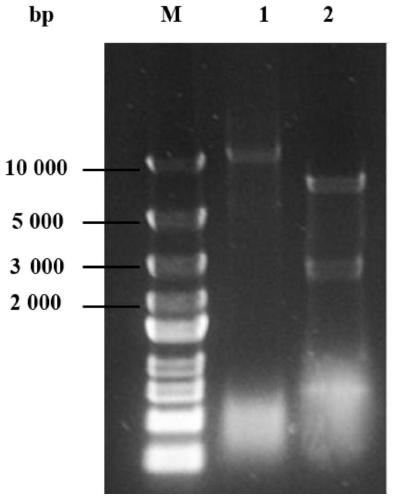

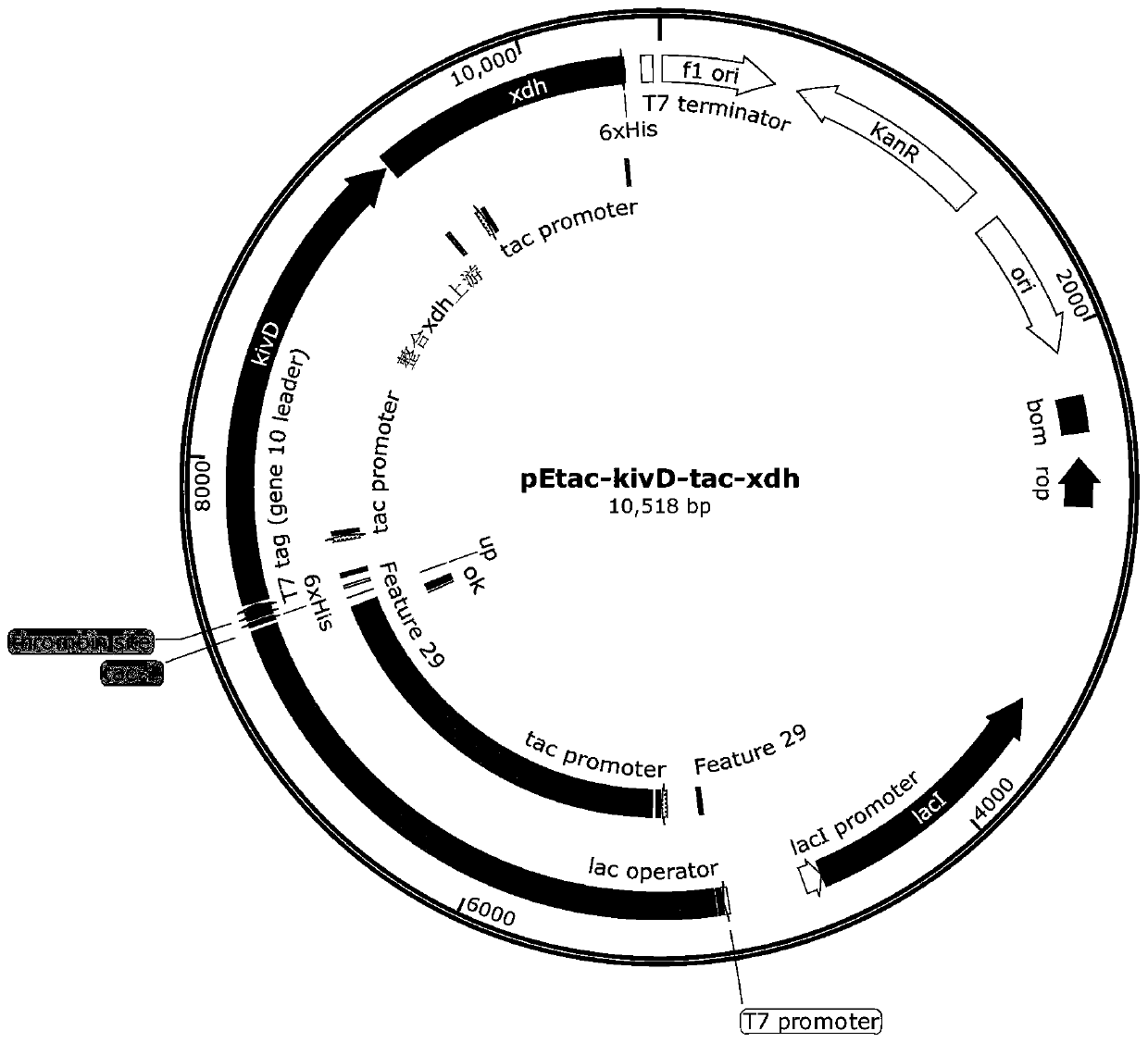

[0049] Embodiment 1: Construction of recombinant Klebsiella pneumoniae

[0050] Specific steps are as follows:

[0051] Synthesize the gene yjhG (SEQID No.6) encoding xylose dehydratase derived from Escherichia coli (Escherichia coli); combine the synthesized gene kivD encoding 2-ketoisovalerate decarboxylase with the recombinant plasmid pEtac-kivD-tac -xdh (recorded in the literature "Jing P Y, Cao X, Lu X Y, etc. Modification of an engineered Escherichia coli by a combined strategy of deleting branch pathway, fine-tuning xylose isomerase expression, and substituting decarboxylase to improve1,2,4-butanetriol production[J].Journal of Bioscience and Bioengineering, 2018,126(5):547-552.", the nucleotide sequence of the tac promoter is shown in SEQ ID No.7) by restriction endonuclease Xba I After digestion with Nco I, ligation was performed to obtain the ligation product; the ligation product was transformed into Escherichia coli (Escherichiacoli) BL21 to obtain the transformati...

Embodiment 2

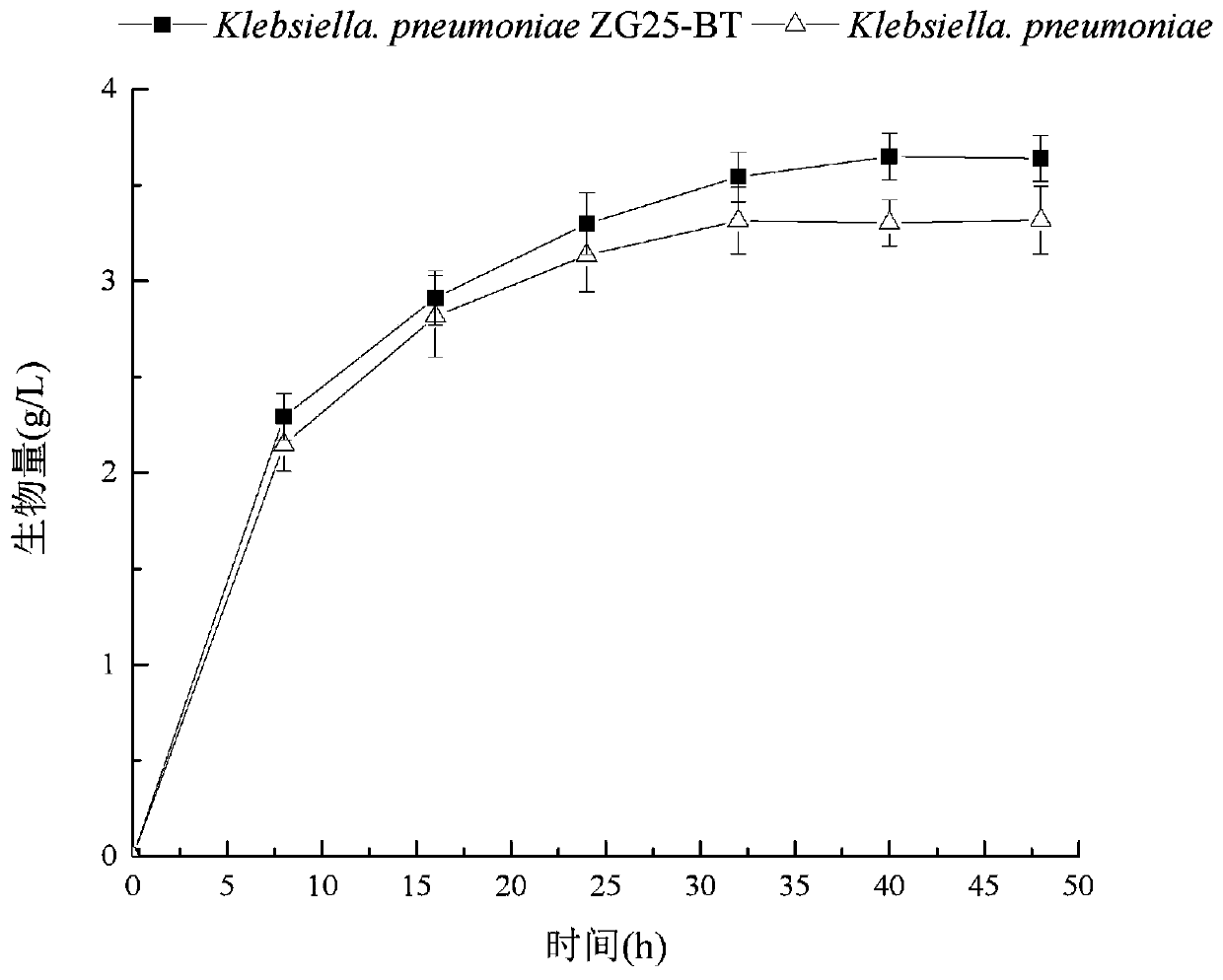

[0052] Example 2: Coproduction of 1,3-propanediol and D-1,2,4-butanetriol

[0053] Specific steps are as follows:

[0054] With Klebsiella pneumoniae (Klebsiella Pneumoniae) JI22914 as a control, the single colony of recombinant Klebsiella pneumoniae JI22914 / pEtac-yjhG-tac-kivD-tac-xdh obtained in Example 1 was streak-inoculated on LB solid medium cultured at 37°C for 12-14 hours to form a single colony; pick a single colony and inoculate it into LB liquid medium, cultivate it at 37°C and 100rpm for 12 hours to obtain a first-class seed liquid; inoculate according to 1% (v / v) Transfer the primary seed solution to the new LB liquid medium, cultivate it for 8h at 37°C and 100rpm to obtain the secondary seed solution; transfer the secondary seed solution to the In the fermentation medium, shake culture at 37° C. and 150 rpm for 48 hours to obtain a fermentation broth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com