A silver-platinum bonding wire utilizing silver-platinum coating and its preparation process

A preparation process and bonding wire technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electric solid-state devices, etc., can solve the problems of unfavorable popularization and application, complicated preparation process, and poor performance, and achieve simple and easy operation, reduce Manufacturing cost and the effect of reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation process of silver-platinum bonding wire utilizing silver-platinum coating:

[0034] 1) Raw material pretreatment: wash the metal raw material, dry it for later use;

[0035] 2) Melting and casting: In a hydrogen atmosphere, take 78% metallic silver Ag and 6% metallic platinum Pt for vacuum melting at a temperature of 850°C, then cool down to 740°C, and dope with 1% metallic tin Sn and 1.58% metallic manganese Mn , 1.72% metal indium In and other trace elements 1% metal copper Cu, 0.5% metal calcium Ca, 0.2% metal boron B, obtained by vacuum melting at constant temperature to obtain silver-platinum alloy materials;

[0036] 3) Rough wire drawing: rough wire drawing of silver-platinum alloy material to obtain 1mm silver-platinum bonding wire;

[0037] 4) Surface activation treatment: deoxidize the surface of the silver-platinum bonding wire with a reduced carbon material, and then immerse the silver-platinum bonding wire in a mixed solution of 15mol / L aceti...

Embodiment 2

[0042] A preparation process of silver-platinum bonding wire utilizing silver-platinum coating:

[0043] 1) Raw material pretreatment: wash the metal raw material, dry it for later use;

[0044] 2) Melting and casting: In a hydrogen atmosphere, take 79% metallic silver Ag and 5.5% metallic platinum Pt for vacuum melting at a temperature of 860°C, then cool down to 750°C, and dope with 1.25% metallic tin Sn and 2% metallic manganese Mn , 1.45% metal indium In and other trace elements 0.3% metal boron B, 1% metal lanthanum La, vacuum melting at constant temperature to obtain silver-platinum alloy materials;

[0045] 3) Rough wire drawing: rough wire drawing of silver-platinum alloy material to obtain 2mm silver-platinum bonding wire;

[0046] 4) Surface activation treatment: deoxidize the surface of the silver-platinum bonding wire with a reduced carbon material, and then immerse the silver-platinum bonding wire in a mixed solution of 16mol / L acetic acid and 6mol / L nitric acid ...

Embodiment 3

[0051] A preparation process of silver-platinum bonding wire utilizing silver-platinum coating:

[0052] 1) Raw material pretreatment: wash the metal raw material, dry it for later use;

[0053] 2) Melting and casting: Under a hydrogen atmosphere, take 80% metallic silver Ag and 5% metallic platinum Pt for vacuum melting at a temperature of 865°C, then cool down to 750°C, and dope with 1.6% metallic tin Sn and 2% metallic manganese Mn , 1.45% metal indium In and other trace elements 0.27% metal calcium Ca, 0.5% metal lanthanum La, vacuum melting at constant temperature to obtain silver-platinum alloy materials;

[0054] 3) Rough wire drawing: rough wire drawing of silver-platinum alloy material to obtain 3mm silver-platinum bonding wire;

[0055] 4) Surface activation treatment: deoxidize the surface of the silver-platinum bonding wire with a reduced carbon material, and then immerse the silver-platinum bonding wire in a mixed solution of 18mol / L acetic acid and 6mol / L nitric...

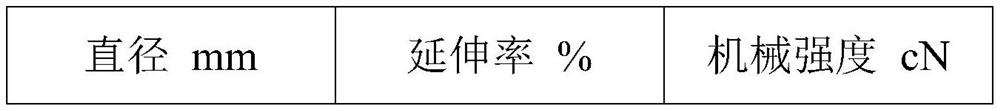

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com