Carbonnanoscroll, preparation method and application thereof and carbon nano belt

A carbon nano-roll and carbon nano-dot technology, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of high requirements for carbon nano-roll preparation conditions, limitation of mass production and application, and complicated preparation steps. Achieve the effect of easy large-scale batch preparation, good photothermal conversion performance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

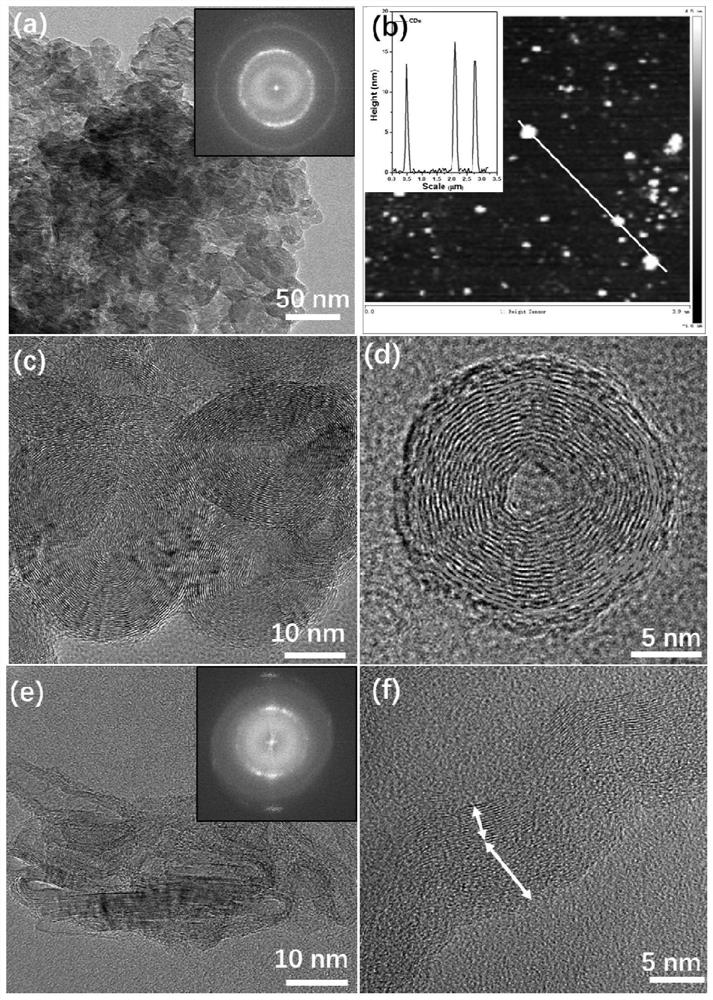

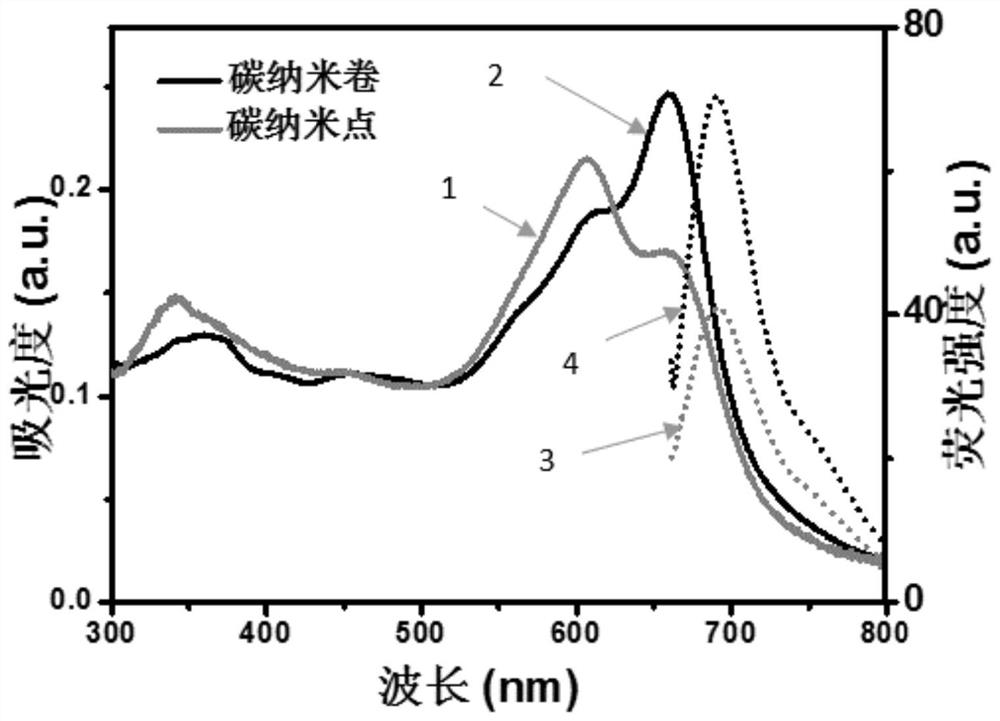

[0025] Some embodiments of the present invention provide a method for preparing carbon nanoscrolls, which includes: placing carbon nanodots in a polar aprotic solvent for solvothermal reaction to form carbon nanoscrolls, wherein the surface of carbon nanodots It has an active site, and the active site includes one or more of hydroxyl, carboxyl and amino groups.

[0026] The inventor found in the long-term research and practice process that in the process of preparing carbon nanomaterials by solvothermal method, the choice of solvent has a great influence on the reaction process, specifically, in the process of preparing carbon nanodots by solvothermal method Since the process of generating carbon nano-dots is a dehydration process, the carbon nano-dots will not continue to grow due to the presence of water and the proton solvent used in the original solvothermal reaction after the reaction to generate carbon nano-dots. Based on this, the inventor has done a lot of research and...

Embodiment 1

[0052] 1g of citric acid and 3g of urea were dissolved in 30mL of DMSO to obtain a transparent solution, placed in a 50mL polytetrafluoroethylene autoclave, and reacted at 160°C for 4h, and 60mL of ethanol was added to the reacted solution to obtain a black solid, which was washed with water and centrifuged ( 8000rpm, 5min), freeze-dried to obtain dark blue powder, that is, carbon nanodots.

[0053] Dissolve the above-mentioned carbon nano-dots in dimethyl sulfoxide according to the dosage of 1g: 30mL, place the obtained dimethyl sulfoxide solution in a 50ml polytetrafluoroethylene autoclave, heat the reaction, and the reaction temperature is 180°C. The reaction time is 4 hours, the heating method is oven heating, and 60 mL of ethanol is added to the reacted solution to obtain a black solid, which is washed with water, centrifuged, and freeze-dried to obtain a powder, that is, carbon nanovolumes.

Embodiment 2

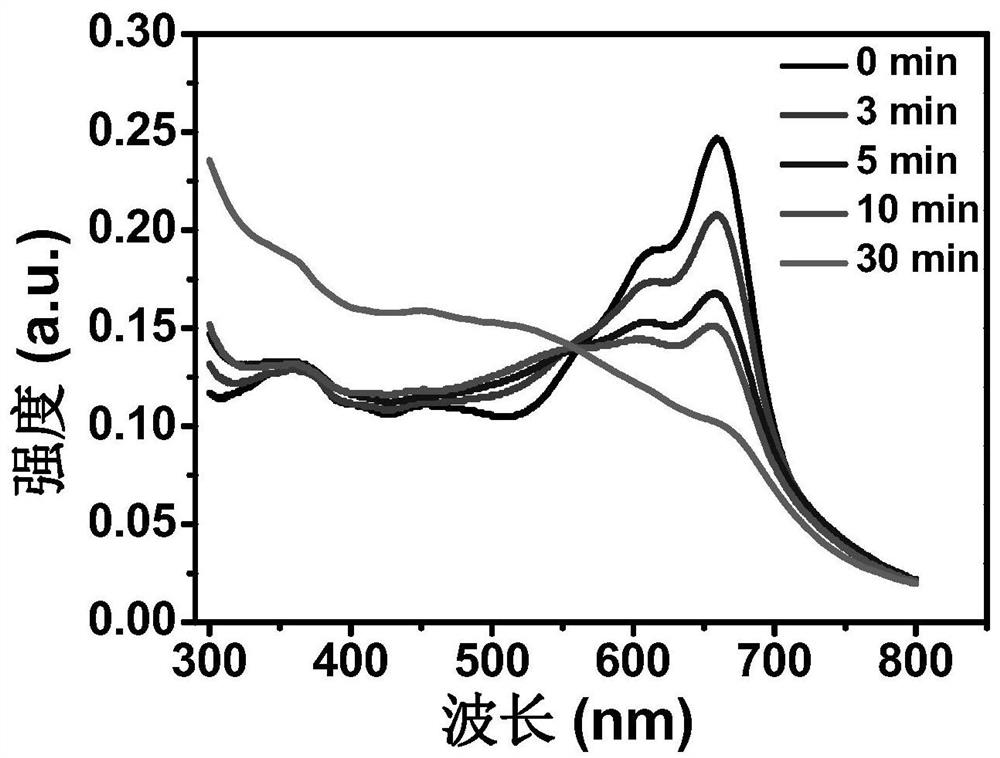

[0055] Dissolve the carbon nanoscrolls obtained in Example 1 in water at a concentration of 0.1 mg / mL, and irradiate the carbon nanoscrolls solution with a 655nm laser for 30 minutes, and the laser power is preferably 1w / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com