Chelating agent, cleaning agent and preparation method of chelating agent

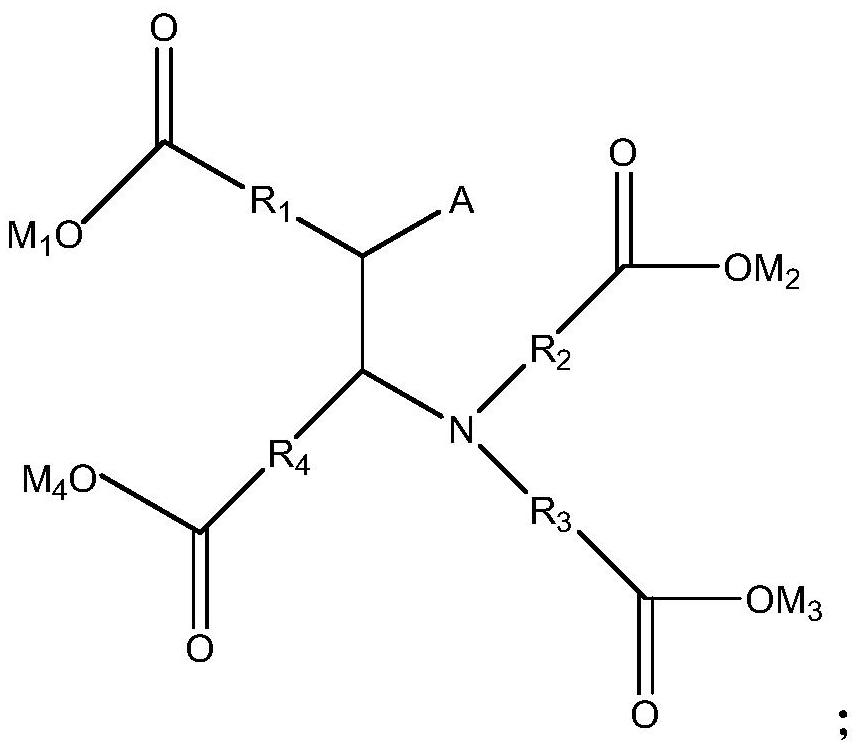

A chelating agent and compound technology, applied in the field of organic chemical synthesis, can solve the problems of low performance of IDS chelating metal, carcinogenicity and high production cost, and achieve the effects of excellent storage stability, strong chelating ability and high chelating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

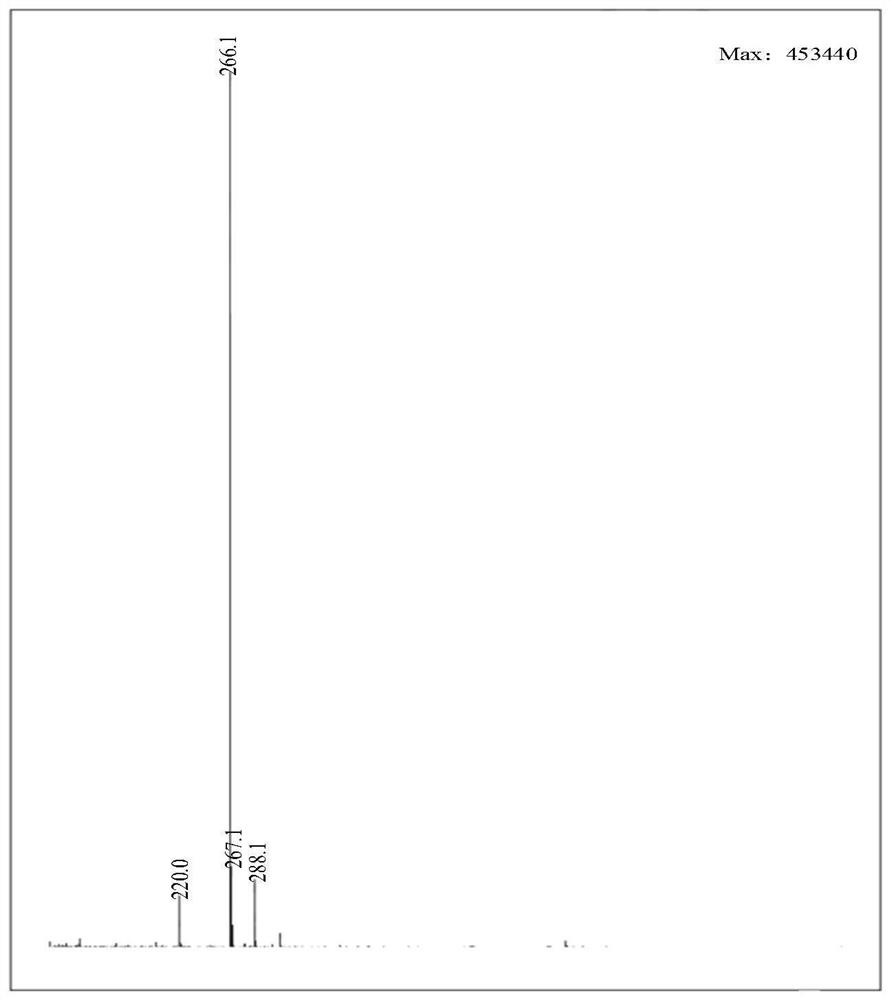

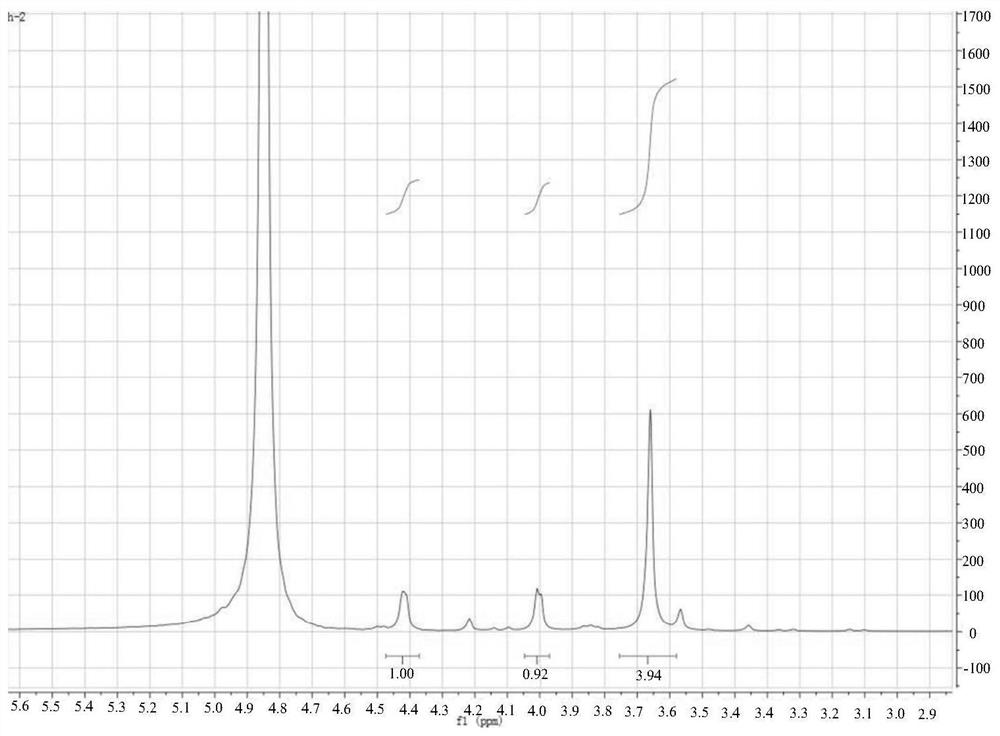

[0151] Add 196g of maleic anhydride to a 2000mL four-necked bottle, then add 200g of deionized water, and hydrolyze at 25°C for 1 hour. Then use 50% (mass fraction) NaOH solution to adjust the pH of the reaction system to 6.0-6.5, and keep the temperature not exceeding 45°C. After the dropwise addition, the temperature was raised to 55° C. and stirred for 15 minutes. Add 14g of sodium tungstate to the reaction system and stir for 45min. Add 30% hydrogen peroxide solution dropwise within 90 minutes, and add 50% NaOH to the system to adjust the pH. During the reaction, the pH is 6.0-7.5, and the temperature does not exceed 75°C. After adding hydrogen peroxide dropwise, raise the temperature to 65°C, stir for 3h, then add 266g of iminodiacetic acid, stir for 1h, add 160g of solid sodium hydroxide, then raise the temperature to 80°C, react for 5h, cool down to obtain N,N-diethylcarboxylate The solution of acid-3-hydroxydisuccinic acid tetrasodium salt, that is, the solution of ...

Embodiment 2

[0153] Add 232g of maleic acid into a 2000mL four-neck flask, then add 200g of deionized water, and stir at 45°C for 1h. Then use 50% (mass fraction) NaOH solution to adjust the pH of the reaction system to 5.0-6.5, and keep the temperature not exceeding 55°C. After the dropwise addition, the temperature was raised to 55° C. and stirred for 15 minutes. Add 16g of sodium tungstate to the reaction system and stir for 45min. Add 30% hydrogen peroxide solution dropwise within 90 minutes, and at the same time add 50% NaOH to the system to adjust the pH. During the reaction, the pH is 6.0-7.0, and the temperature does not exceed 75°C. After adding hydrogen peroxide dropwise, raise the temperature to 60-65°C, stir for 3h, then add 266g of iminodiacetic acid, stir for 1h, add 160g of solid sodium hydroxide, then raise the temperature to 90°C, react for 8h, cool down to obtain N,N-di The solution of ethyl carboxylate-3-hydroxydisuccinic acid tetrasodium salt, that is, the solution o...

Embodiment 3

[0155]Add 232g of fumaric acid into a 2000mL four-neck flask, then add 200g of deionized water, and stir at 45°C for 1h. Then use 50% (mass fraction) NaOH solution to adjust the pH of the reaction system to 5.0-6.5, and keep the temperature not exceeding 55°C. After the dropwise addition, the temperature was raised to 55° C. and stirred for 15 minutes. Add 20g of sodium tungstate to the reaction system and stir for 45min. Add 30% hydrogen peroxide solution dropwise within 90 minutes, and add 50% NaOH to the system to adjust the pH. During the reaction, the pH is 6.0-7.0, and the temperature does not exceed 75°C. After adding hydrogen peroxide dropwise, raise the temperature to 60-65°C, stir for 3h, then add 266g of iminodiacetic acid, stir for 1h, add 160g of solid sodium hydroxide, then raise the temperature to 90°C, react for 8h, cool down to obtain N,N-di The solution of ethylcarboxylate-3-hydroxydisuccinic acid tetrasodium salt, that is, the solution of the chelating ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com