Adhesive for corrugated cardboard explosion-proof line and preparation method thereof

A corrugated cardboard and adhesive technology, applied in the field of corrugated cardboard explosion-proof adhesives and its preparation, can solve the problems of insignificant effect and insufficient toughness of cardboard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

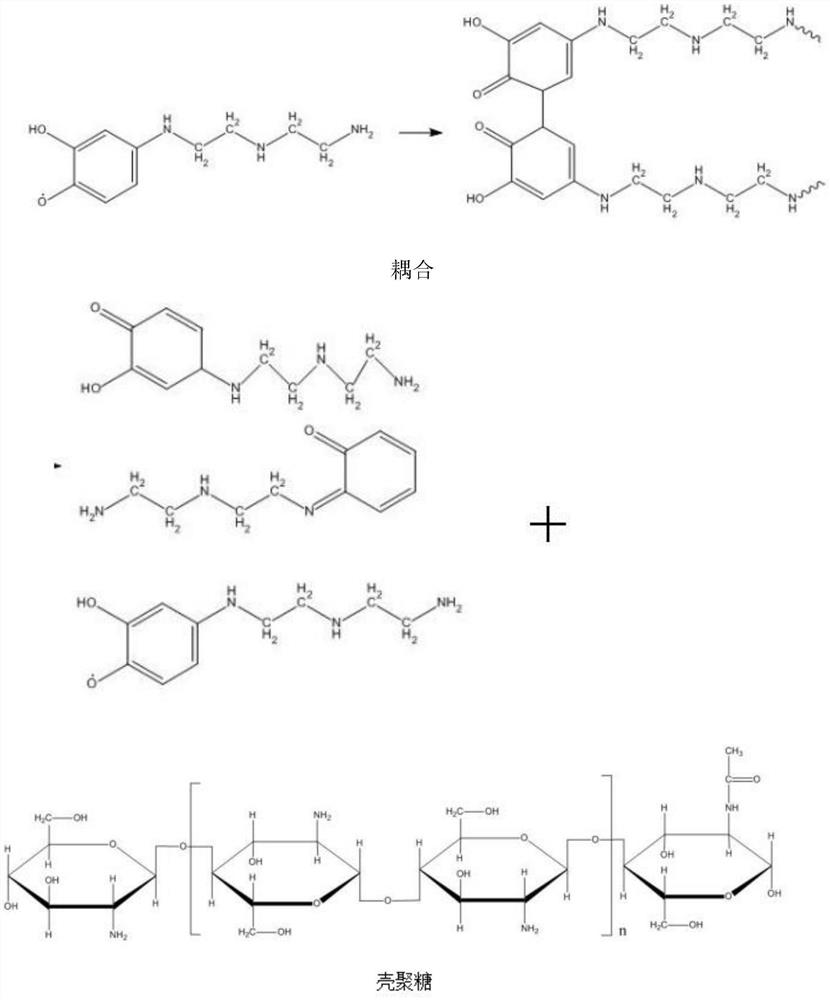

[0017] The preparation method of the above-mentioned adhesive for corrugated cardboard explosion-proof line is specifically: first mix chitosan solution, corn starch solution, and toughening agent according to the required ratio to obtain the pre-preparation liquid, and then add catalase to the pre-preparation liquid Mix evenly, then adjust the pH value of the system to 8-9 with hydrochloric acid, and raise the temperature to 70-80°C to react to obtain the adhesive.

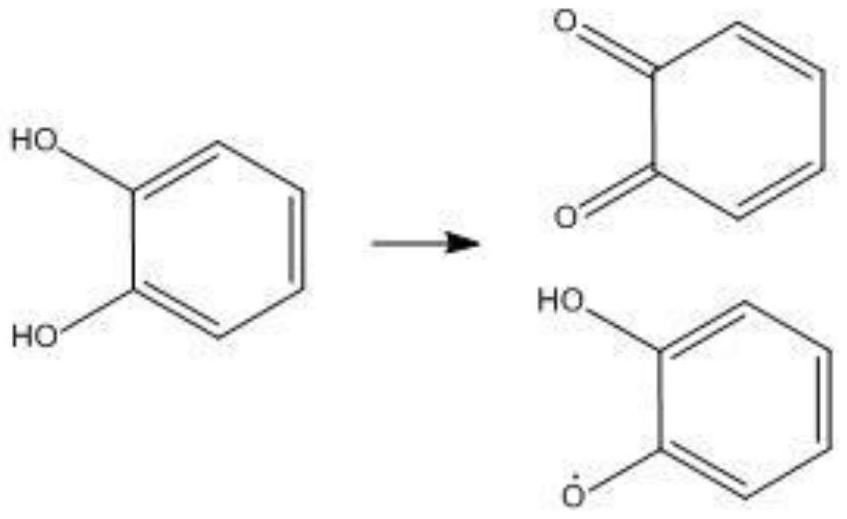

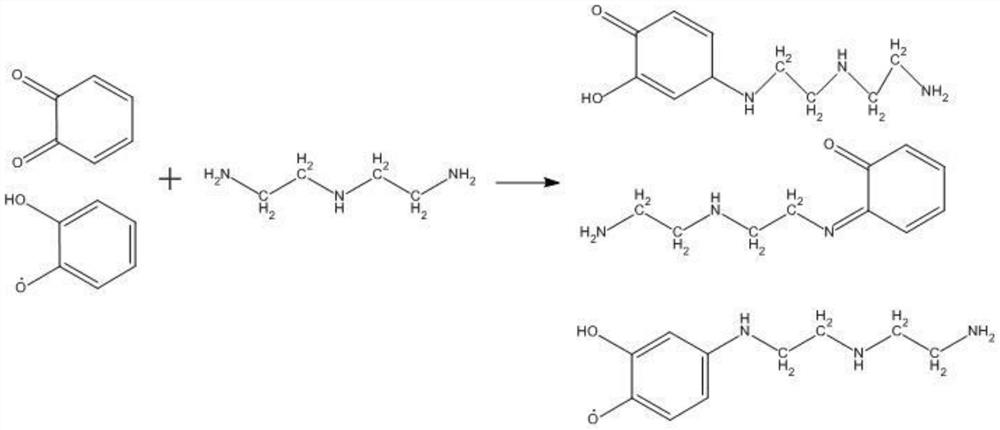

[0018] Principle of the present invention is described as follows:

[0019] The present invention uses catechol and diethylenetriamine to polymerize under the catalysis of catalase to form three kinds of long-chain polymers containing multiple reactive active sites, and these long-chain polymers are combined with chitosan and cellulose of cornstarch And other organic matrix, the fiber molecules of corrugated base paper form intermolecular and intramolecular chemical bonds and hydrogen bonds, so that a high-streng...

Embodiment 1

[0044] An adhesive for corrugated cardboard explosion-proof wire, its raw material composition and weight ratio are: pre-prepared liquid 80, catalase 0.1, the raw material composition and weight ratio of the described pre-prepared liquid are: chitosan solution 40, corn Starch solution 80, toughening agent 10, the raw material composition and weight ratio of described chitosan solution are: chitosan 8, the acetic acid solution that volume percent content is 1% according to 80, the raw material composition of described cornstarch solution and its weight ratio The weight ratio is: corn starch 15, distilled water 80, polyvinyl alcohol 4, borax 1, defoamer emulsified silicone oil 0.5, isothiazolone 0.5, calcium sulfate whisker 3, the raw material composition and weight of the toughening agent The ratio is: Tris 10, Distilled water 100, Catechol 5, Diethylene triamine 5.

[0045] The preparation method of the adhesive for the above-mentioned corrugated cardboard explosion-proof line...

Embodiment 2

[0051] The difference with Example 1 is:

[0052] The adhesive for corrugated cardboard explosion-proof line, its raw material composition and weight ratio are: pre-prepared liquid 90, catalase 0.2, the raw material composition and weight ratio of the described pre-prepared liquid are: chitosan solution 50, corn Starch solution 90, toughening agent 17, the raw material composition and weight ratio of described chitosan solution are: chitosan 9, the acetic acid solution that volume percent content is 1% according to 90, the raw material composition of described cornstarch solution and its weight ratio The weight ratio is: corn starch 18, distilled water 90, polyvinyl alcohol 5, borax 1.5, defoamer 0.7, isothiazolone 0.7, calcium sulfate whisker 4, the raw material composition and weight ratio of the toughening agent are : Trishydroxymethylaminomethane 12, distilled water 110, catechol 7, diethylenetriamine 7.

[0053] In the step of preparing the adhesive, the pH of the system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com