Preparation method of moringa oleifera leaf propolis enzyme and enzyme composition

A technology of wood leaf bee and gelatin enzyme, which is applied in the direction of bacteria used in food preparation, food science, and the function of food ingredients, can solve the problems of general extraction effect, poor taste, and complicated extraction process of flavonoids, and shorten the fermentation process. time, increase market competitiveness, and shorten fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

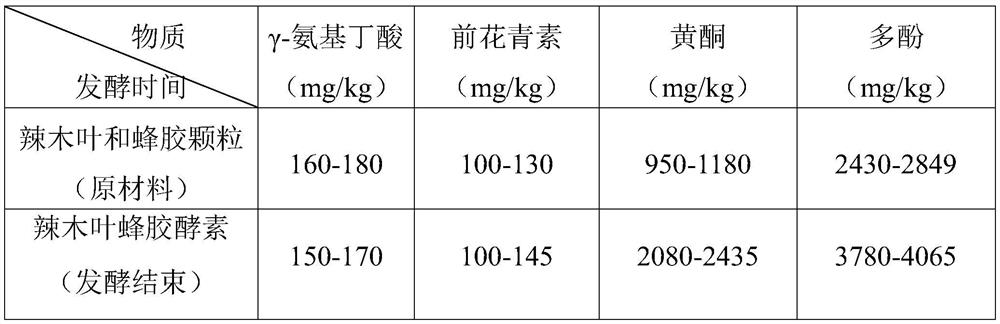

Examples

Embodiment 1

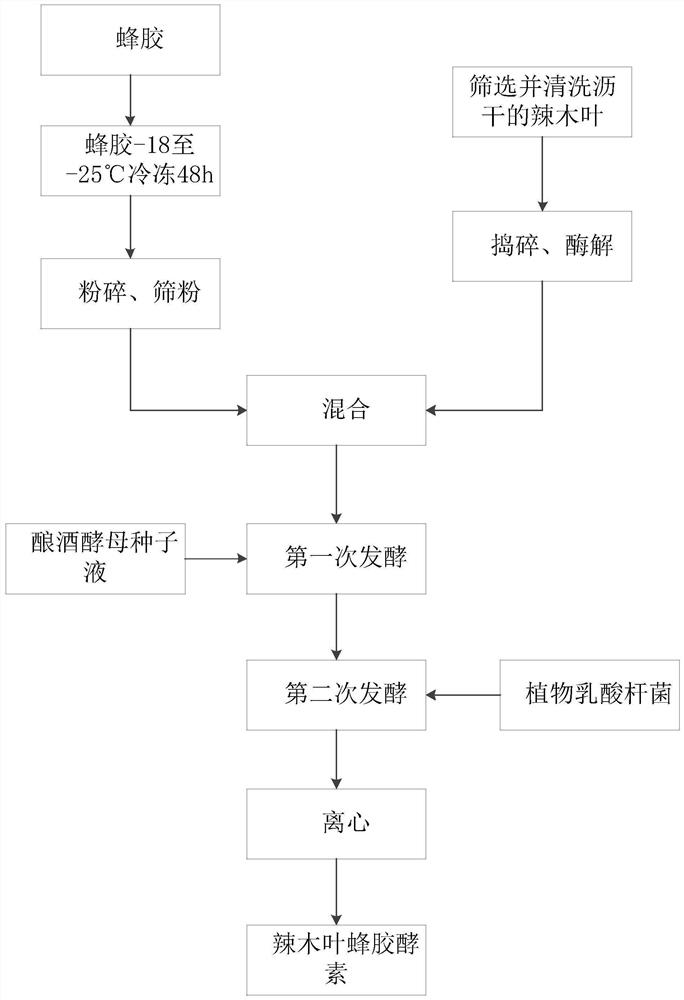

[0040] A preparation method of Moringa leaf propolis enzyme, comprising the following steps:

[0041] Step 1: Raw material pretreatment

[0042] Pretreatment of Moringa leaves: First, mash the Moringa leaves that have been screened, washed and drained, and add vitamin C with a mass ratio of 0.005:100 to the Moringa leaves when mashing. Then the mashed leaves of Moringa oleifera were added to an active enzyme solution containing acid protease, pectinase, and cellulase at a pH value of 3.8, and enzymolysis was carried out at a temperature of 45°C for 3.5 hours to obtain active leaves of Moringa oleifera For the enzymatic hydrolyzate, the active Moringa leaf enzymolyzate was inactivated at a temperature of 80° C. for 10 minutes to obtain the Moringa leaf enzymolyzate. Wherein, the mass ratio of acid protease, pectinase, cellulase and Moringa leaf is 0.2:1:1.8:100; The mass ratio of water is 1:3.

[0043]Propolis pretreatment: first place impurity-free propolis at -18°C for pre...

Embodiment 2

[0052] A preparation method of Moringa leaf propolis enzyme, comprising the following steps:

[0053] Step 1: Raw material pretreatment

[0054] Pretreatment of Moringa leaves: First, mash the Moringa leaves that have been screened, washed and drained, and add vitamin C with a mass ratio of 0.03:100 to the Moringa leaves when mashing. Then the mashed Moringa leaves were added to an active enzyme solution containing acid protease, pectinase, and cellulase at a pH of 4.4, and enzymolysis was carried out at a temperature of 55°C for 5 hours to obtain active Moringa leaf enzymes For the hydrolyzate, the active Moringa leaf enzymatic hydrolyzate was inactivated for 30 minutes at a temperature of 100° C. to obtain the Moringa leaf enzymolyzate. Wherein, the mass ratio of acid protease, pectinase, cellulase and Moringa leaf is 0.5:1.5:2.3:100; The mass ratio of water is 1:8.

[0055] Propolis pretreatment: first place impurity-free propolis at -25°C for pre-cooling for 48 hours, t...

Embodiment 3

[0064] A preparation method of Moringa leaf propolis enzyme, comprising the following steps:

[0065] Step 1: Raw material pretreatment

[0066] Pretreatment of Moringa leaves: First, mash the Moringa leaves that have been screened, washed and drained, and add vitamin C with a mass ratio of 0.005:100 to the Moringa leaves when mashing. Then the mashed leaves of Moringa oleifera were added to an active enzyme solution containing acid protease, pectinase, and cellulase at a pH value of 4.2, and enzymolysis was carried out at a temperature of 55° C. for 4.5 hours to obtain active leaves of Moringa oleifera Enzymolyzed liquid, the active Moringa leaf enzymolyzed liquid was inactivated at a temperature of 80° C. for 25 minutes to obtain the Moringa leaf enzymolyzed liquid. Wherein, the mass ratio of acid protease, pectinase, cellulase and Moringa leaf is 0.5:1.4:2.2:100; The mass ratio of water is 1:7.

[0067] Propolis pretreatment: first place impurity-free propolis at -20°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com