Hemostatic sponge as well as preparation method and application thereof

A technology of composite sponge and hemostatic material, applied in the field of hemostatic sponge and its preparation, can solve the problems of non-biodegradation, toxic degradation products, hindering biosafety and clinical trial approval, etc., and achieves ingenious preparation method, death prevention, design clever effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: the preparation of sodium alginate / chitosan / fucoidan sulfate composite sponge

[0051] method:

[0052] (1) Sodium alginate is dissolved in deionized water to prepare an aqueous sodium alginate solution with a mass percent concentration of 10%; chitosan is dissolved in an aqueous acetic acid solution with a volume percent concentration of 1% to prepare a mass percent concentration of 10%. chitosan solution.

[0053] (2) Under the condition of mixer 500r / min, according to chitosan: sodium alginate is the weight ratio of 1:3, mix sodium alginate aqueous solution and chitosan solution, keep stirring for 2h, take it out, and pour it into a fixed mold , sealed and allowed to stand overnight to obtain a gel.

[0054] (3) The gel was taken out, frozen in liquid nitrogen, and then transferred into a freeze dryer to freeze-dry to obtain a cross-linked body.

[0055] (4) Preparation of fucoidan sulfate solution: dissolving fucoidan sulfate in deionized water to p...

Embodiment 2

[0059] Example 2: General Characterization of the Composite Sponge of Example 1

[0060] method:

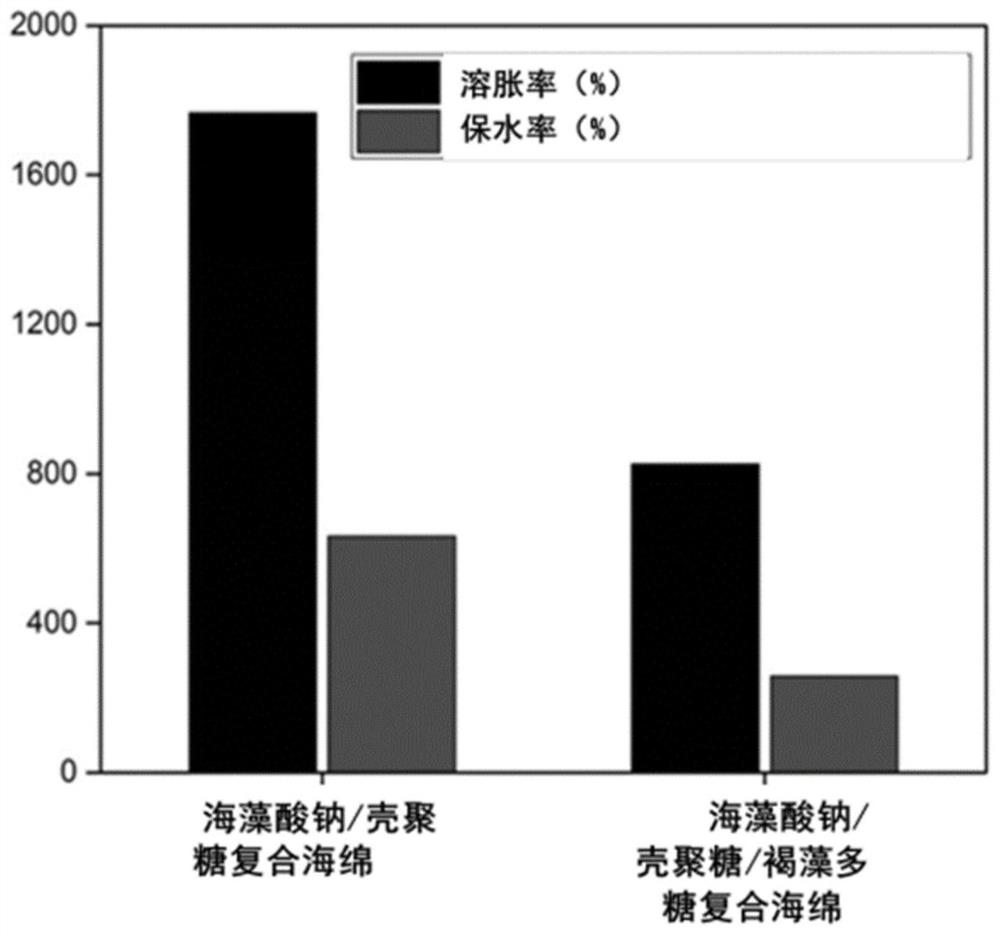

[0061] The sodium alginate / chitosan / fucoidan composite sponge prepared in Example 1 is compared with the sodium alginate / chitosan composite sponge without adding fucoidan sulfate, and the conventional swelling rate and water retention of the sponge are carried out test.

[0062] The test method of swelling rate: Soak the sponge in PBS, take it out after 2 minutes, absorb excess water, weigh it, compare it with the sponge before absorbing water, and calculate the swelling rate.

[0063] Calculation of water retention rate: After the sponge is saturated and absorbs water, put it in a centrifuge and centrifuge at a speed of 5000r / min for 3 minutes, then weigh the sponge after centrifugation, and compare the weight with the sponge before the initial water absorption to calculate the water retention Rate.

[0064] result:

[0065] The swelling rate and water retention rate of sodi...

Embodiment 3

[0066] Embodiment 3: the preparation of sodium alginate / chitosan / fucoidan sulfate composite sponge

[0067] method:

[0068] (1) Sodium alginate is dissolved in deionized water to prepare a 10% sodium alginate aqueous solution by mass percent concentration; chitosan is dissolved in 1% acetic acid by volume concentration to prepare 10% by mass percent concentration Chitosan solution;

[0069] (2) Under the condition of mixer 500r / min, according to chitosan: sodium alginate is the weight ratio of 1:3, mix sodium alginate aqueous solution and chitosan solution, keep stirring for 2h, take it out, and pour it into a fixed mold , sealed and allowed to stand overnight to obtain a gel.

[0070] (3) Take out the gel, freeze it in a refrigerator at -20°C overnight for freezing, and then transfer it to a freeze dryer to freeze-dry to obtain a cross-linked body.

[0071] (4) Preparation of fucoidan sulfate solution: dissolve fucoidan sulfate in deionized water to prepare an aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com