A welding process method of thick plate narrow gap tungsten argon arc welding

A technology of argon tungsten arc welding and welding process, which is applied in the direction of welding equipment, welding accessories, arc welding equipment, etc., and can solve the problem that the magnetic control arc method cannot weld easily magnetized materials, the gas protection of the weld seam, and the welding gap Solve problems such as limited width range, achieve the effect of improving welding construction efficiency, improving welding quality, metallurgical properties and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A thick plate narrow gap tungsten argon arc welding process, comprising the following steps:

[0070](1) Groove opening and groove treatment: 16Mn plate thickness 150mm, U-shaped groove on one side, 10mm narrow gap reserved, blunt edge reserved, rust removal at the groove; groove size: ① round bottom Arc transition radius R = 2.0mm; ② The protruding length of the blunt edge is 2.5mm, and the thickness of the blunt edge is 2.5mm; ③ The gap between the two sides is 1.0mm; ④ The groove angle is 0°;

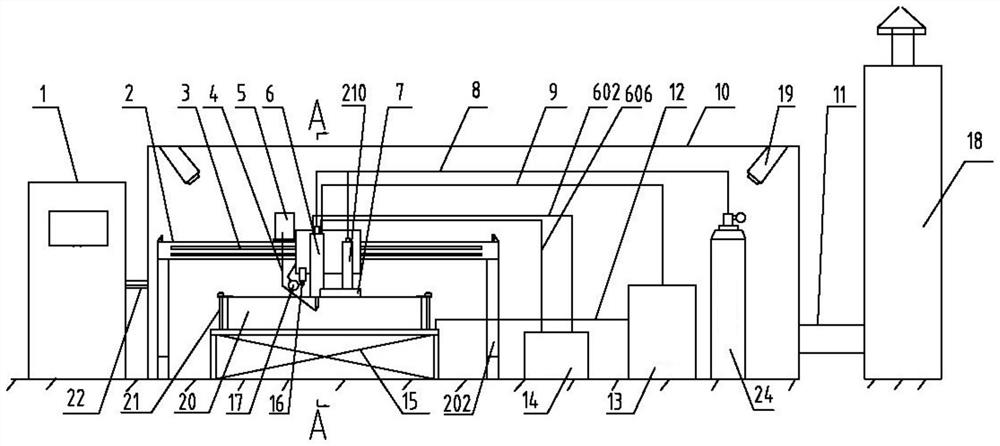

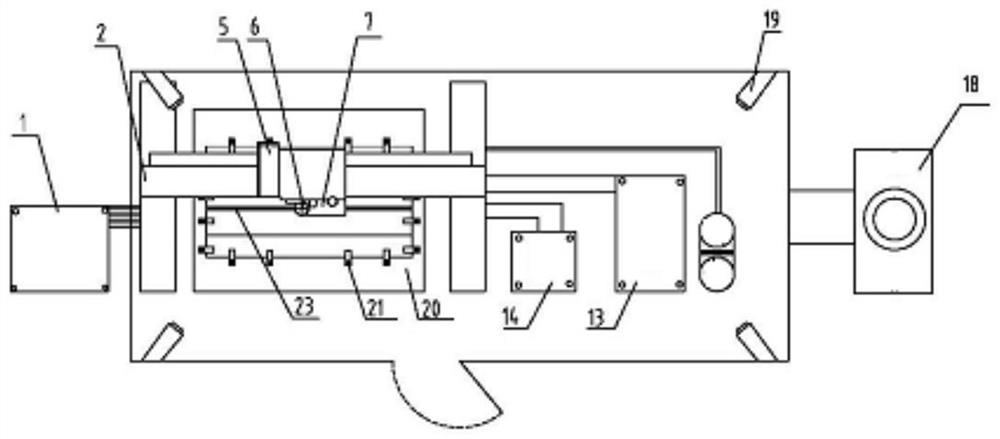

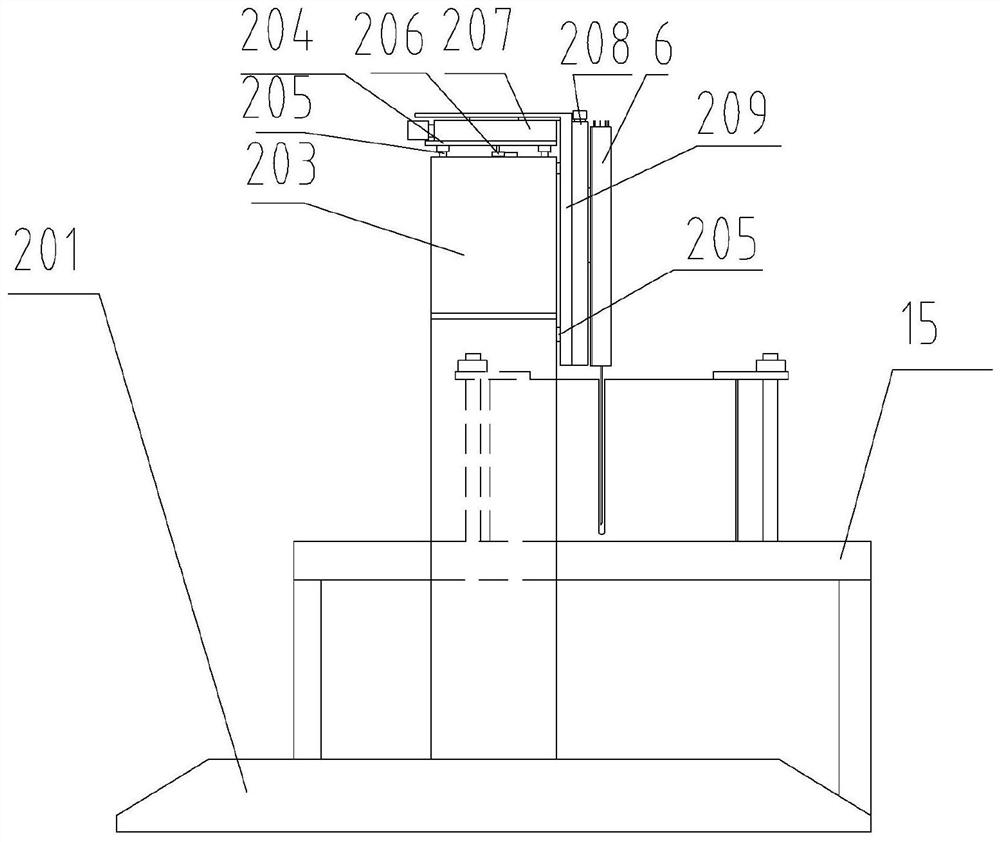

[0071] (2) Clamping: A narrow-gap tungsten argon arc welding equipment is used. The equipment includes a frame, a workbench, a welding torch, a wire feeding system, a water cooling system, a laser sensor, and an arc pressure sensor; the top of the welding torch passes through the air intake pipe and the gas cylinder. The top of the welding torch is connected to the welding power supply through the power wire. The water cooling system includes the water inlet pipe, the return p...

Embodiment 2

[0092] A thick plate narrow gap tungsten argon arc welding process, the steps are as described in embodiment 1, the difference is:

[0093] In step (1), the thickness of the 16Mn plate is 300 mm, U-shaped grooves are opened on both sides, and the gap width is 10 mm;

[0094] In step (2), the welding seam of the workpiece is fixed vertically downwards, and the method of vertical welding is adopted; two welding equipment are selected, respectively located on both sides of the workpiece, and welded vertically;

[0095] In step (3), a tungsten electrode with a diameter of 6.0 is selected, and the extension distance of the tungsten electrode is 150 mm;

[0096] In step (5), 50 layers are respectively welded on both sides of the 300mm thick plate, welding in layers, and the interlayer temperature is controlled below 100°C. The wire feeding speed is 260cm / min, the arc voltage is 18V, the welding current is 320A, the wire preheating current is 70A, the welding speed is 8cm / min, and t...

Embodiment 3

[0098] A thick plate narrow gap tungsten argon arc welding process, the steps are as described in Example 1, the difference is that in step (1), the groove size is: ① bottom arc transition radius R = 1.0mm ;②The protruding length of the blunt edge is 1.0mm, and the thickness of the blunt edge is 1.0mm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com