A water-swellable fracturing temporary plugging agent with controllable degradation, preparation method and application thereof

A temporary plugging agent and fracturing technology, which is applied in chemical instruments and methods, earthwork drilling, drilling composition, etc. Ideal and other problems, to achieve the effect of adjustable degradation time, improved degradation performance and strength, high toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the controllable degradation of the water puffing type fracturing temporary plugging agent provided in the present embodiment is as follows:

[0036] In a 500mL flask add 6g of bone gel and 200g of distilled water, heated at 60 °C until the bone gel is completely dissolved, nitrogen replaces the air, respectively, 22 g of acrylic acid and 8 g of sodium hydroxide are added to fully neutralize, followed by 28 g of acrylamide, ultrasonic dispersion is uniformly placed in a water bath at 60 °C for heating and stirring, and then 0.025 g of N, N- methylene bisacrylamide, 0.2 g of potassium persulfate, 1.5 g of sulfonated asphalt, 1.0 g of sodium hydroxymethyl cellulose, The reaction was carried out for 4h, and the initial product obtained by the reaction was placed in an 80 °C blast drying box to dry to constant weight, and the product was crushed to obtain a controllable degradation of the puffed fracturing temporary plugging agent.

Embodiment 2

[0038] The preparation method of the controllable degradation of the water puffing type fracturing temporary plugging agent provided in the present embodiment is as follows:

[0039]In a 500mL flask add 5g of gelatin and 200g of distilled water, heated at 60 °C until the gelatin is completely dissolved, nitrogen is used to displace the air, respectively, 30g of acrylic acid and 10g of sodium hydroxide are added to full neutralize, followed by 30g of acrylamide, ultrasonic dispersion is uniformly placed in a water bath at 60 °C for heating and stirring, and then 0.03g of N, N- methylene bisacrylamide, 0.28g of potassium persulfate, 1.2g of sulfonated asphalt, 1.2g of hydroxymethyl cellulose sodium, The reaction was carried out for 4h, and the initial product obtained by the reaction was placed in an 80 °C blast drying box to dry to constant weight, and the product was crushed to obtain a controllable degradation of the puffed fracturing temporary plugging agent.

Embodiment 3

[0041] In the 500mL flask added 3g of gelatin and 200g of distilled water, heated at 60 °C until the gelatin was completely dissolved, nitrogen was used to replace the air, respectively, 15g of acrylic acid and 6g of sodium hydroxide were added to fully neutralize, and then 25g of acrylamide was added, and then placed in a 60 °C water bath for heating and stirring, and then 0.02g of N, N-methylenebiacrylamide, 0.2g of potassium persulfate, 0.5g of sulfonated asphalt, 0.8g of sodium hydroxyethyl cellulose were added for 4h The initial product obtained by the reaction is placed in an 80 °C blast drying box to dry to constant weight, and the product is crushed to obtain a controllable degradation of the puffed fracturing temporary plugging agent.

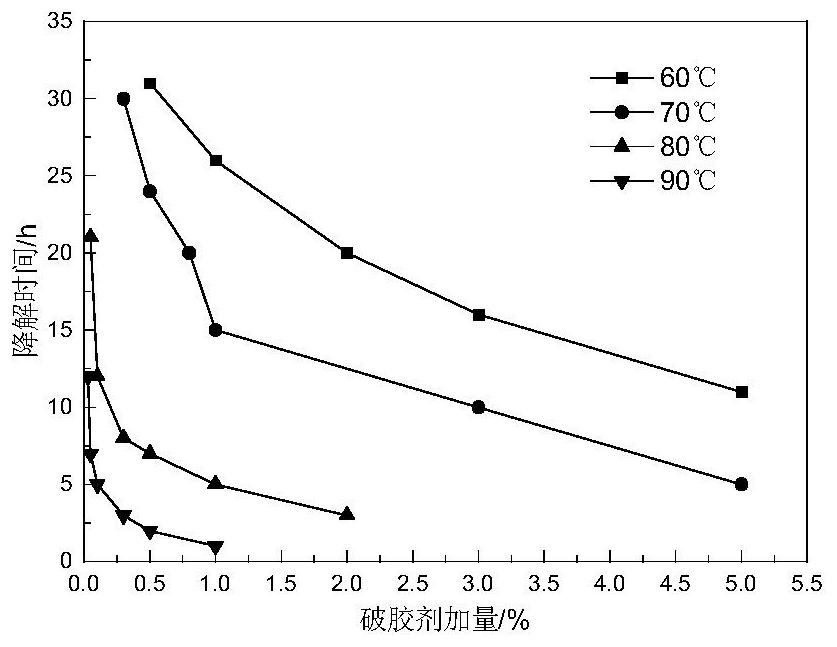

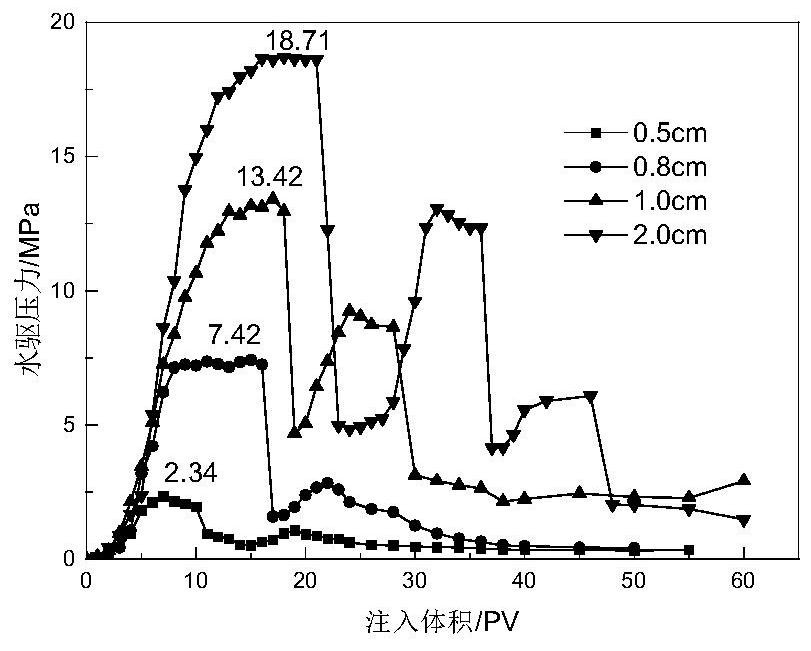

[0042] Second, the performance test of degradable fracturing temporary plugging agent

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com