Waste vinasse utilization method

A technology of distiller's grains and distiller's grains, which is applied in the field of brewing, can solve the problems of unutilized distiller's grains, and achieve the effects of improving the availability of microorganisms, lingering aftertaste, and promoting the proliferation of esterification microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

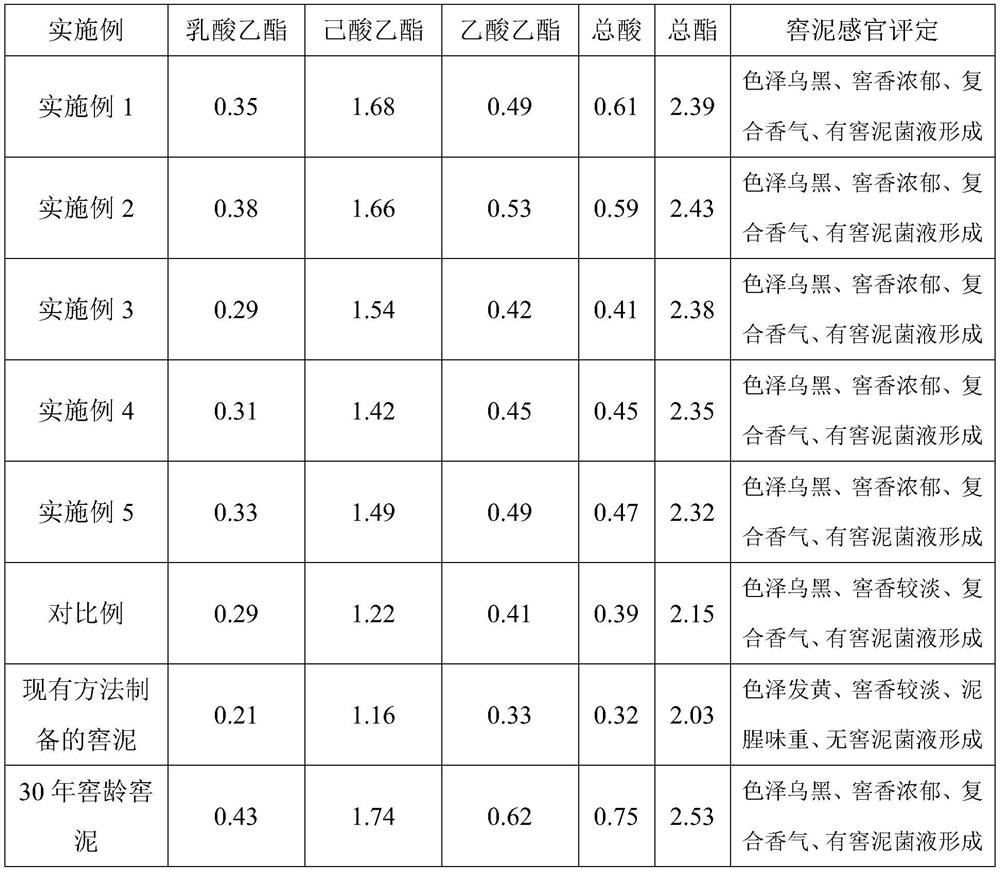

Examples

Embodiment 1

[0034] A method for utilizing waste distiller's grains, comprising the steps of:

[0035] S1. In terms of parts by mass, take 100 parts of discarded grains, and after ultrasonic pretreatment of the discarded grains, mix with 10 parts of undistilled double-wheel bottom grains, 5 parts of cellulase, 0.5 parts of phytase, 1 part of manganese sulfate, 0.3 parts of zinc acetate, 1.5 parts of calcium acetate, 0.1 parts of potassium chloride, 0.06 parts of niacin, 0.02 parts of inositol, 0.6 parts of sophorolipids, and 0.5 parts of chitin were mixed evenly, and fermented in a fermentation tank for 15 days to obtain the fermented mixture;

[0036] S2. Dehydrating and extruding the fermentation mixture to obtain distiller's grain squeeze liquid and distiller's grains;

[0037] S3. Mix 20 parts of distiller's grains squeezed liquid, 20 parts of yellow water, and 40 parts of tail water in parts by weight to obtain a mixed solution;

[0038] S4, in parts by weight, layer and layer 100 p...

Embodiment 2

[0041]S1, in parts by mass, take 50 parts of waste grains, after ultrasonic pretreatment of waste grains, 20 parts of undistilled double-wheel bottom grains, 2 parts of cellulase, 1 part of phytase, 0.5 parts of manganese sulfate, 0.5 part of zinc acetate, 1 part of calcium acetate, 0.3 part of potassium chloride, 0.02 part of niacin, 0.1 part of inositol, 0.3 part of sophorolipid, and 1 part of chitin are mixed evenly and placed in a fermenter for 7 days to obtain fermented mixture;

[0042] S2. Dehydrating and extruding the fermentation mixture to obtain distiller's grain squeeze liquid and distiller's grains;

[0043] S3. Mix 40 parts of distiller's grains squeezed liquid, 10 parts of yellow water, and 50 parts of tail water in parts by weight to obtain a mixed solution;

[0044] S4, spread 40 parts by weight of yellow mud, 30 parts of pit skin mud, 5 parts of high-quality old pit mud, 6 parts of fresh pond mud, 3 parts of Daqu powder, and 70 parts of distiller's grains, s...

Embodiment 3

[0047] S1. In terms of parts by mass, take 50 parts of discarded grains, and after ultrasonic pretreatment of the discarded grains, combine with 20 parts of undistilled double-wheel bottom grains, 0.5 parts of manganese sulfate, 0.5 parts of zinc acetate, 1 part of calcium acetate, chloride 0.3 parts of potassium, 0.02 parts of niacin, 0.1 parts of inositol, 0.3 parts of sophorolipids, and 1 part of chitin were mixed evenly, and placed in a fermentation tank for fermentation for 7 days to obtain a fermentation mixture;

[0048] S2. Dehydrating and extruding the fermentation mixture to obtain distiller's grain squeeze liquid and distiller's grains;

[0049] S3. Mix 40 parts of distiller's grains squeezed liquid, 10 parts of yellow water, and 50 parts of tail water in parts by weight to obtain a mixed solution;

[0050] S4, spread 40 parts by weight of yellow mud, 30 parts of pit skin mud, 5 parts of high-quality old pit mud, 6 parts of fresh pond mud, 3 parts of Daqu powder, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com