A low-carbon brake disc and its manufacturing method

A technology of carbon brake discs and manufacturing methods, applied in the direction of brake discs, brake types, brake components, etc., can solve problems such as high production costs, achieve the effects of reducing high production costs, improving smelting efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

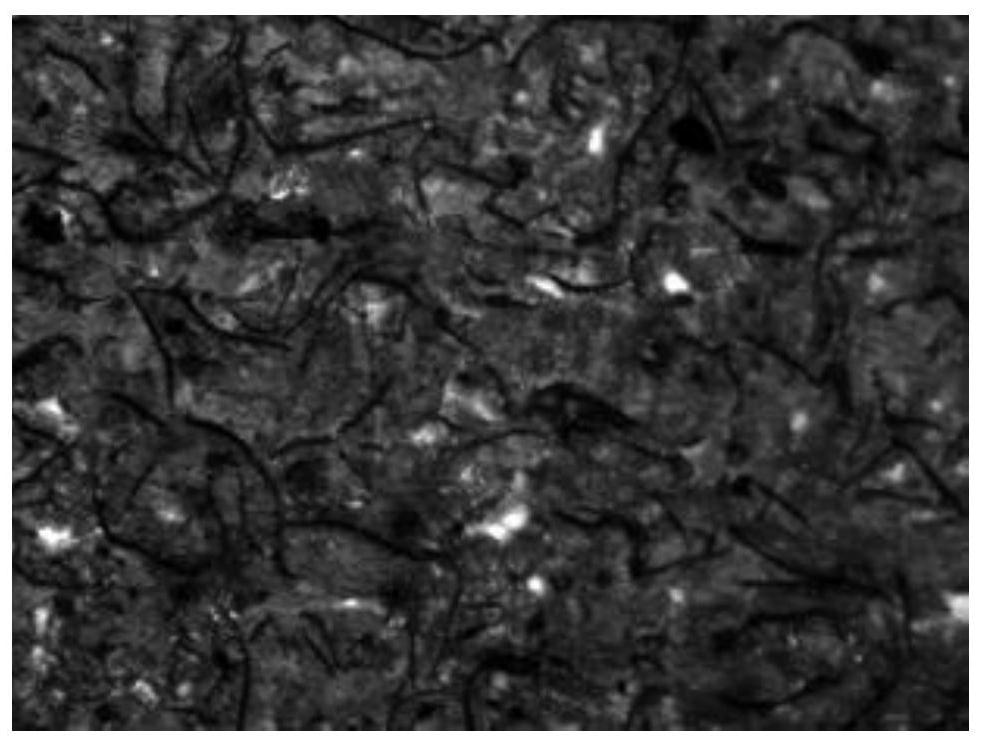

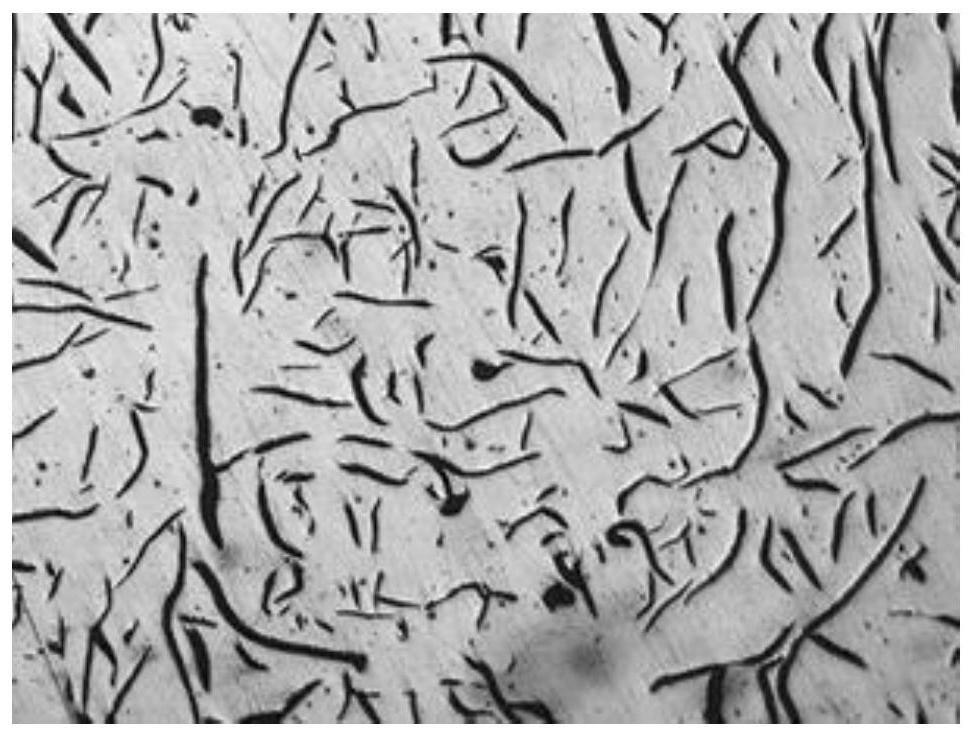

Image

Examples

Embodiment 1

[0050] This embodiment provides a low-carbon brake disc, which is made of the following components in weight percentage:

[0051] 3.12% carbon, 2.23% silicon, 0.70% manganese, 0.06% phosphorus, 0.06% sulfur, 0.01% antimony, 93.82% iron. agent.

[0052] The manufacturing method of described a kind of low-carbon brake disc, comprises the following steps:

[0053] S1 ingredients, calculate the content of each component according to the requirements, and weigh them for use;

[0054] S2 smelting, the prepared raw materials are put into the intermediate frequency induction furnace in batches for smelting, and carburizer is added, the power is adjusted to 450kW within 1 to 20 minutes, and the power is gradually adjusted to 1440kW after 20 minutes, and iron filings, scrap steel and Returning to the furnace charge, the recarburizer is added in batches with the iron filings, and the power is gradually increased to heat up and keep warm until all the charge is melted. The composition o...

Embodiment 2

[0068] The low-carbon brake disc provided in this embodiment is made of the following components in weight percentage:

[0069] 3.15% carbon, 2.20% silicon, 0.75% manganese, 0.05% phosphorus, 0.08% sulfur, 0.015% antimony, 93.76% iron. agent.

[0070] The manufacturing method of described a kind of low-carbon brake disc, comprises the following steps:

[0071] S1 ingredients, calculate the content of each component according to the requirements, and weigh them for use;

[0072] S2 smelting, the prepared raw materials are put into the intermediate frequency induction furnace in batches for smelting, and carburizer is added, the power is adjusted to 450kW within 1 to 20 minutes, and the power is gradually adjusted to 1440kW after 20 minutes, and iron filings, scrap steel and Returning to the furnace charge, the recarburizer is added in batches with the iron filings, and the power is gradually increased to heat up and keep warm until all the charge is melted. The composition of...

Embodiment 3

[0080] This embodiment provides a low-carbon brake disc, which is made of the following components in weight percentage:

[0081] 3.10% carbon, 2.25% silicon, 0.75% manganese, 0.08% phosphorus, 0.08% sulfur, 0.01% antimony, 93.73% iron. agent.

[0082] The manufacture method of described a kind of low-carbon brake disc, comprises the following steps:

[0083] S1 ingredients, calculate the content of each component according to the requirements, and weigh them for use;

[0084] S2 smelting, the prepared raw materials are put into the intermediate frequency induction furnace for smelting in batches, and carburizer is added, the power is adjusted to 450kW within 1 to 20 minutes, and the power is gradually adjusted to 1440kW after 20 minutes, and iron filings, scrap steel and Returning to the furnace charge, the recarburizer is added in batches with the iron filings, and the power is gradually increased to heat up and keep warm until all the charge is melted. The composition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com