Method for testing content of residual dimethyl sulfoxide in polyacrylonitrile precursor in carbon fiber production process

A polyacrylonitrile, production process technology, applied in the field of testing the residual dimethyl sulfoxide content in polyacrylonitrile raw silk, can solve the problems of high test equipment requirements, high cost, complicated use, etc., and achieve low and accurate detection requirements The effect of high test and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

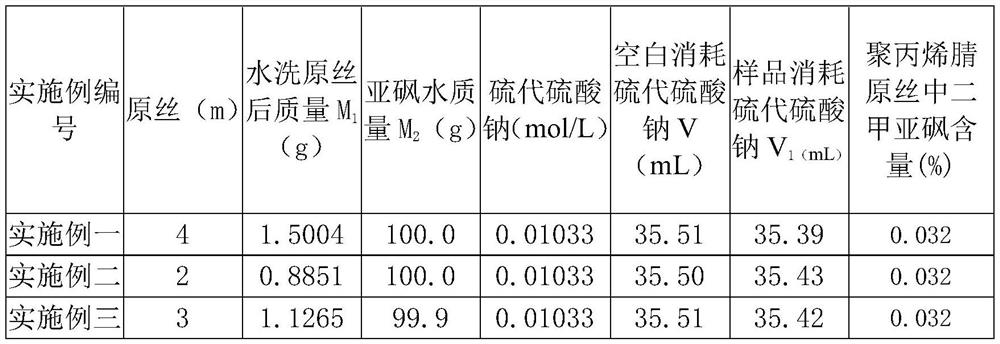

Embodiment 1

[0038] This embodiment is a method for testing the content of residual dimethyl sulfoxide in polyacrylonitrile precursors during the production of carbon fibers, and its specific process is:

[0039] Step 1: Measure 4m polyacrylonitrile precursor and put it into a 1000mL round bottom flask, add 300mL deionized water in the flask;

[0040] Step 2: Add 10 zeolites into the round bottom flask, install a spiral condenser at the mouth of the flask, plug the upper end of the condenser with absorbent cotton, and place it on an electric heating mantle for heating;

[0041] Step 3: Stop heating after the aqueous solution boils for 3 hours, turn off the cooling water when the solution drops to room temperature, and rinse the condenser with 100mL deionized water;

[0042] Step 4: Transfer the solution in the round bottom flask to a 1000mL volumetric flask, pour the polyacrylonitrile precursor with 200mL deionized water, and prepare a 1000mL aqueous solution;

[0043] Step 5: Put the cle...

Embodiment 2

[0053] This embodiment is a method for testing the content of residual dimethyl sulfoxide in polyacrylonitrile precursors during the production of carbon fibers, and its specific process is:

[0054]Step 1: Measure 2m polyacrylonitrile precursor and put it into a 1000mL round bottom flask, add 300mL deionized water in the flask;

[0055] Step 2: Add 10 zeolites into the round bottom flask, install a spiral condenser at the mouth of the flask, plug the upper end of the condenser with absorbent cotton, and place it on an electric heating mantle for heating;

[0056] Step 3: Stop heating after the aqueous solution boils for 3 hours, turn off the cooling water when the solution drops to room temperature, and rinse the condenser with 100mL deionized water;

[0057] Step 4: Transfer the solution in the round bottom flask to a 1000mL volumetric flask, pour the polyacrylonitrile precursor with 200mL deionized water, and prepare a 1000mL aqueous solution;

[0058] Step 5: Put the clea...

Embodiment 3

[0068] This embodiment is a method for testing the content of residual dimethyl sulfoxide in polyacrylonitrile precursors during the production of carbon fibers, and its specific process is:

[0069] Step 1: Measure 3m polyacrylonitrile precursor and put it into a 1000mL round bottom flask, add 300mL deionized water in the flask;

[0070] Step 2: Add 10 zeolites into the round bottom flask, install a spiral condenser at the mouth of the flask, plug the upper end of the condenser with absorbent cotton, and place it on an electric heating mantle for heating;

[0071] Step 3: Stop heating after the aqueous solution boils for 3 hours, turn off the cooling water when the solution drops to room temperature, and rinse the condenser with 100mL deionized water;

[0072] Step 4: Transfer the solution in the round bottom flask to a 1000mL volumetric flask, pour the polyacrylonitrile precursor with 200mL deionized water, and prepare a 1000mL aqueous solution;

[0073] Step 5: Put the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com