Method and device for treating polluted acid containing thallium and arsenic

A technology of arsenic polluted acid and polluted acid, which is applied in the direction of filtration treatment, special treatment targets, multi-stage water treatment, etc. It can solve problems such as difficult discharge or quick return, harsh working environment, and poor quality of supernatant water, etc., to achieve equipment The corrosion is small, the effluent is stable and up to standard, and the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The sewage acid of a smelter contained 956mg / L of arsenic, 10.3mg / L of thallium, 29g / L of sulfuric acid, and the total amount of sewage was 400t / d.

[0054] S1 sewage acid neutralization section

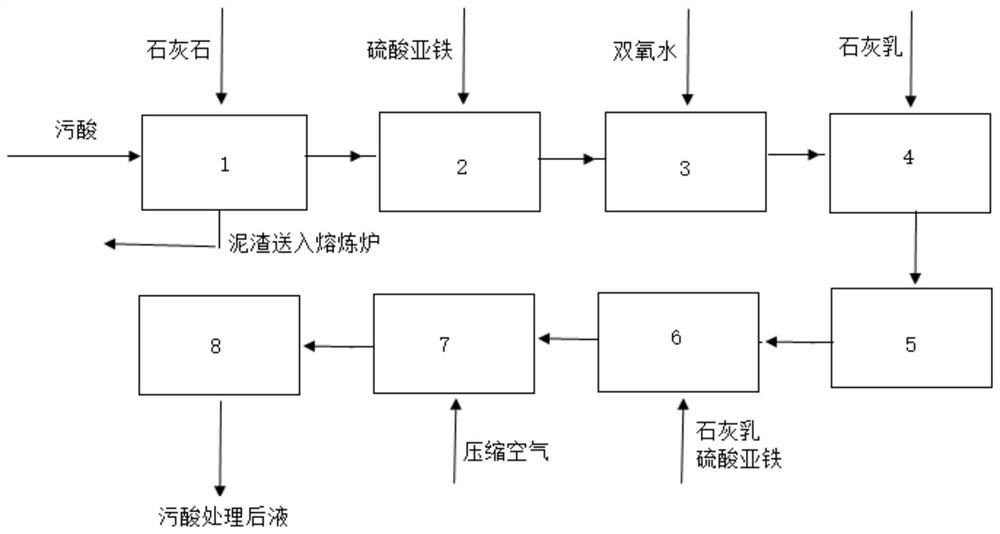

[0055] Such as figure 1 As shown, the thallium- and arsenic-containing polluted acid is sent to the polluted acid neutralization reaction tank 1, and a limestone solution with a mass concentration of 25% is added to the polluted acid neutralization reaction tank 1 to carry out neutralization reaction and control the pH of the effluent clear liquid 2.5, the bottom mud is sent to the filter press for filtration, and the obtained sludge is sent to the smelting furnace for batching, which can effectively use the sludge and reduce the discharge of sludge.

[0056] S2, an oxidation stage

[0057] Send the effluent obtained in S1 into the first reaction tank 2 of the first-stage oxidation section, add ferrous sulfate to the first reaction tank 2 of the first-stage oxidation section...

Embodiment 2

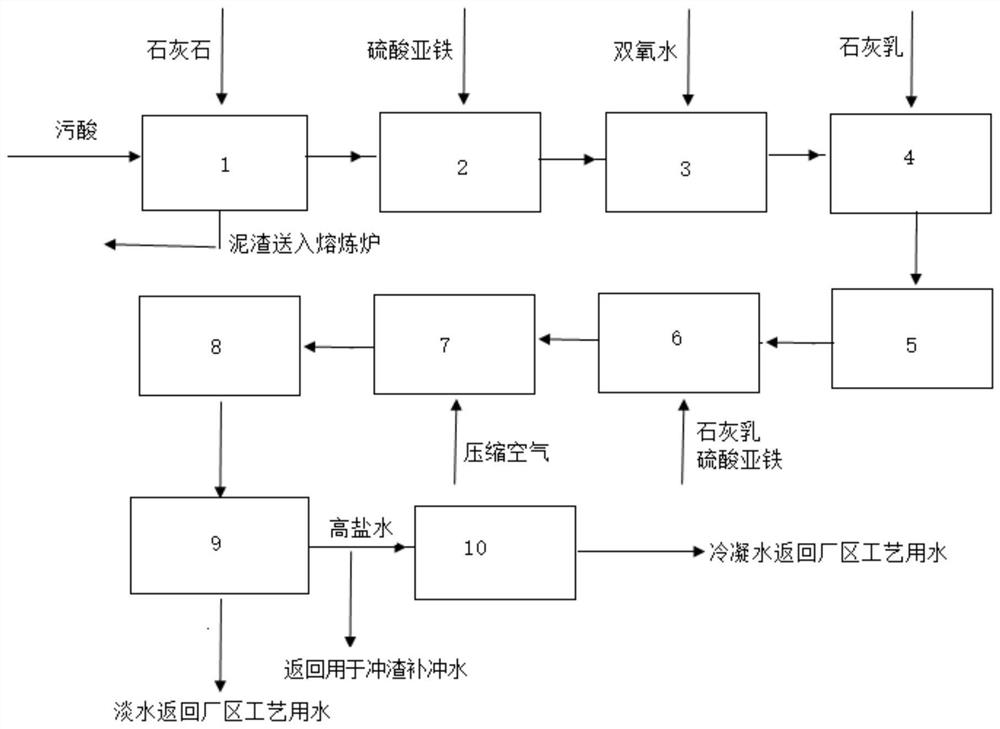

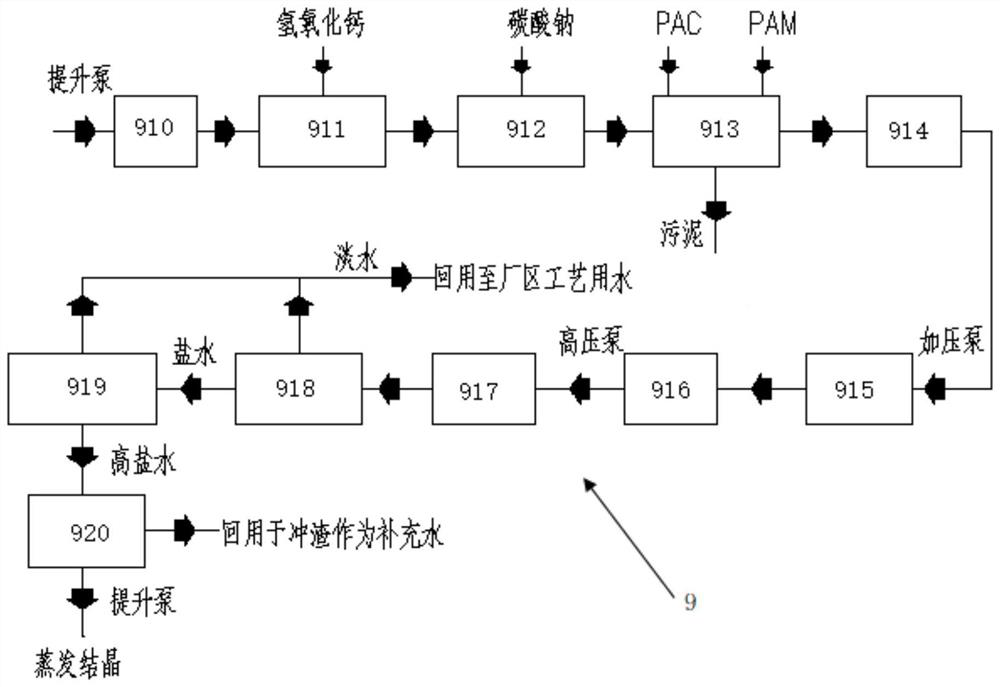

[0064] Such as figure 2 and 3As shown, the liquid after sewage acid treatment obtained in Example 1 is sent into the membrane treatment device 9, the liquid after sewage acid treatment is pressurized to the regulating tank 910 by a pump, and the waste water in the regulating pool 910 is lifted to the first reaction tank 911 by a pump In the first reaction tank 911, calcium hydroxide is added to remove the temporary hardness in the water, and the effluent enters the second reaction tank 912, and sodium carbonate is added to the second reaction tank 912 to remove the permanent hardness in the water, and the effluent enters the coagulation sedimentation pool 913, add coagulant to the coagulation sedimentation tank 913 to further remove various impurities in the water, and pressurize the underflow to the filter press with a sludge pump. The supernatant flows into the pressurized water pool 914, and is sent to the filter 915 by a pressurized pump, and the effluent enters the ultr...

Embodiment 3-4

[0069] The method is the same as in Example 1, except that the content of thallium and arsenic in the polluted acid is different and the pH value control in steps S3 and S4 is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com